Head box for a paper machine

A headbox, paper machine technology, applied in paper machine, paper machine, wet end of paper machine, etc., can solve the problems of increased wear, complexity and large pressure drop of turbulence generators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

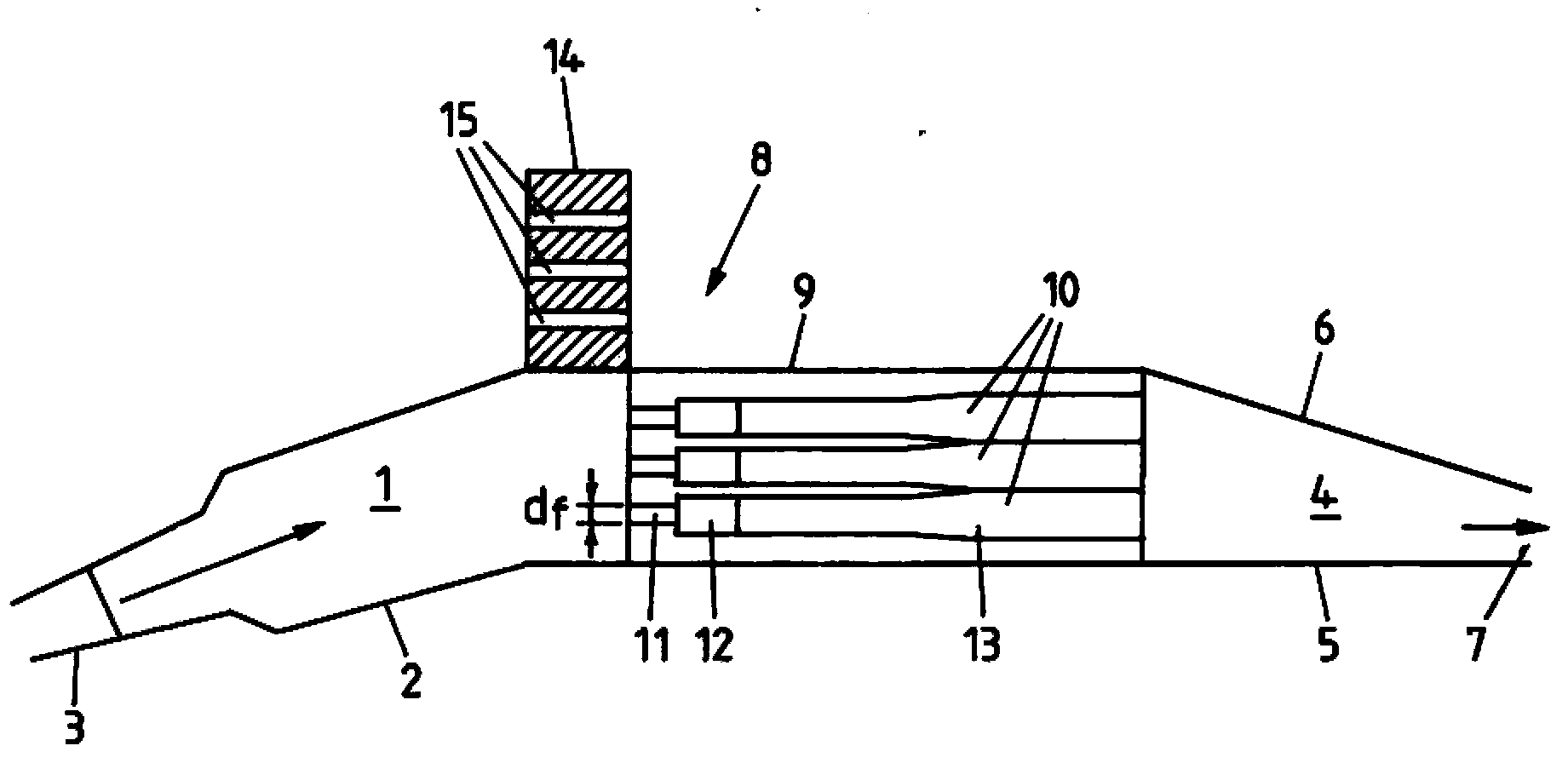

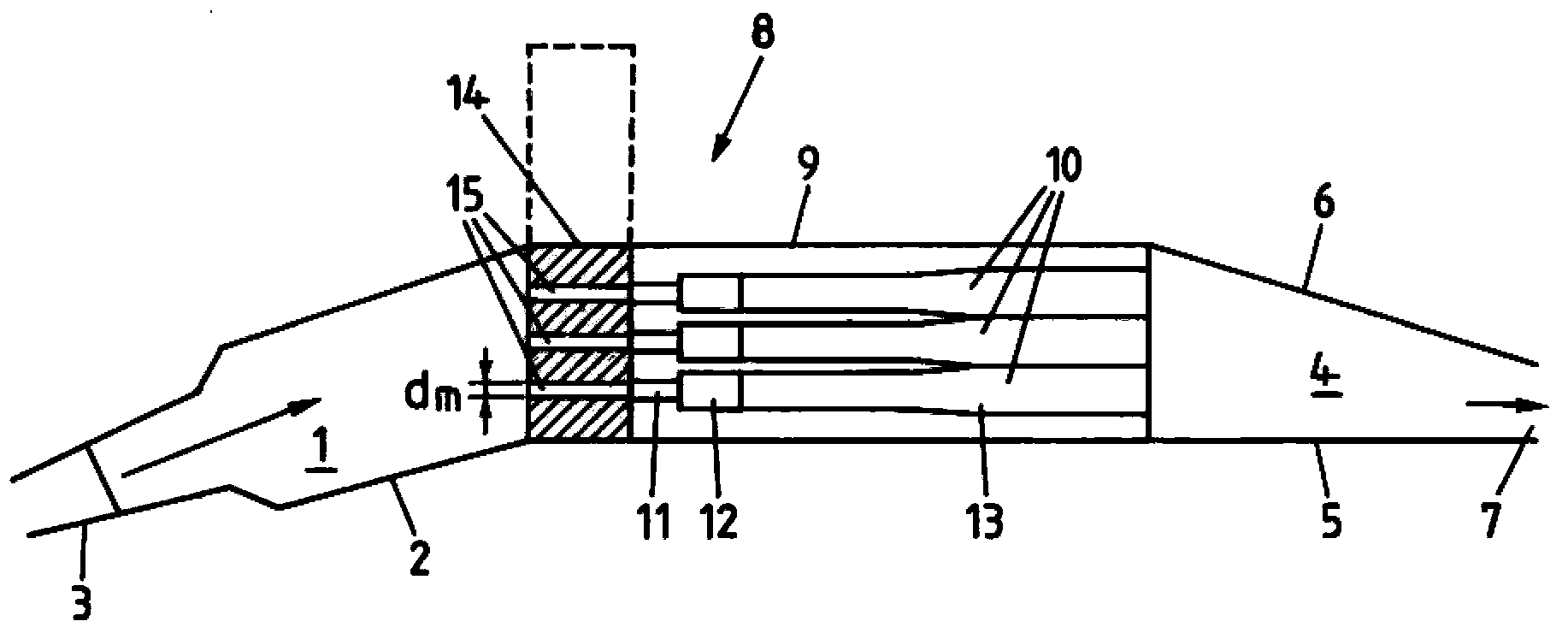

[0010] The headbox distributes the pulp from the central distributor on the conveyor belt of the paper machine. The direction of pulp flow is indicated by arrows. The headbox comprises an inflow chamber 1 at the upstream end. The inflow chamber 1 is surrounded by a housing 2 with a plurality of connectors 3 arranged side by side. On each connector 3 is connected an elastic feed pipe protruding from the central distributor. All feed tubes have the same length. On the downstream end on the opposite side, the headbox comprises an outflow chamber 4 formed between a bottom plate 5 and a cover plate 6 and having a constant cross-section in a transverse direction perpendicular to the flow direction. The volume of the outflow chamber 4 decreases in flow direction so that it ends in a horizontal outflow chute 7 arranged above the conveyor belt.

[0011] A turbulence generator 8 is arranged between the inflow chamber 1 and the outflow chamber 4 . The turbulence generator comprises ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com