Liquid level measuring device for flotation pulp

A liquid level measurement device and floating ball technology, which is applied in buoy liquid level indicators, flotation, solid separation, etc., can solve the problems of floating ball instability, system liquid level value distortion, and hindering free movement of floating balls, etc., to achieve Reduce dynamic friction resistance, prolong service life, and not easily damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

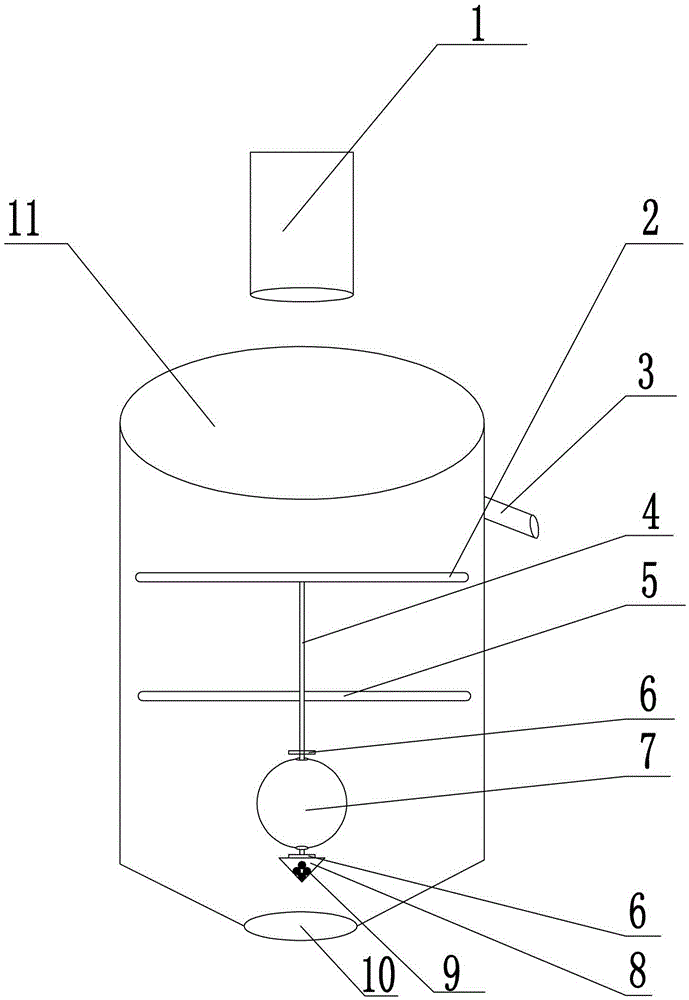

[0021] Such as figure 1 As shown, the liquid level measuring device for flotation pulp of the present invention includes an isolation cylinder 11, a measuring float arranged in the isolation cylinder 11, a laser distance measuring sensor arranged above the axial centerline of the isolation cylinder 11 1. It is characterized in that it also includes a flushing water nozzle 3 arranged on the top of the isolation cylinder 11,

[0022] The measuring float includes a connecting rod 4, a reflecting disk 2 arranged on the top of the connecting rod 4, a balance disk 5 arranged at the bottom of the reflecting disk 2, and two stoppers arranged at the bottom of the connecting rod 4 Card 6, a counterweight cone 8 arranged at the bottom end of the connecting rod 4, a floating ball 7 arranged between the two limit stops 6, and the floating ball...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com