Hydraulic swivel joint not prone to oil leakage

A technology for rotary joints and oil leakage, applied in the direction of pipe components, etc., can solve the problems of easy oil leakage of rotary joints, poor sealing performance, affecting the performance of rotary joints, etc., and achieve the effect of ensuring performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

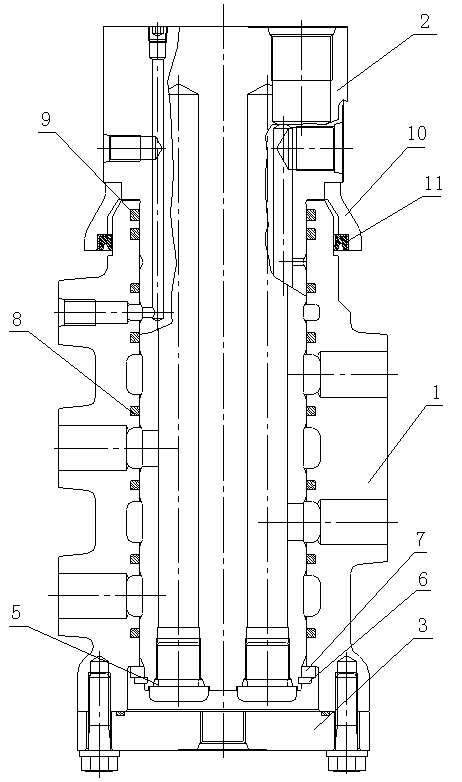

[0011] see figure 1 , the present invention relates to a hydraulic rotary joint not prone to oil leakage, comprising a rotary body 1 and a rotary shaft 2, the bottom end of the rotary shaft 2 is axially inserted from the top end of the rotary body 1, and the top end of the rotary shaft 2 is exposed on the The rotary body 1, the rotary body 1 is connected with the bottom of the rotary shaft 2 through the cover plate 3, the bottom of the oil hole of the rotary shaft 2 is longitudinally provided with a cone plug 4, and an O-shaped plug is arranged between the cover plate 3 and the cone plug 4 Ring I5, between the lower end of the rotary body 1 and the lower end of the rotary shaft 2, a shaft retaining ring 6 and a retaining ring 7 are provided, and a rotary sealing ring 8 and O Shaped ring II9, a dust-proof cover 10 is set on the periphery of the gap between the top of the revolving body 1 and the revolving shaft 2, and a dust-proof ring 11 is arranged between the lower end of th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap