Hydraulic slewing connector with large slewing angle

A technology of swivel joints and swivel angles, applied in the direction of load hanging components, earth movers/excavators, construction, etc., can solve the problems of the influence of the rotary body and the rotary shaft, short life of the pipeline, poor sealing performance, etc., to achieve The effects of reducing labor intensity, long pipeline life, and improving applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

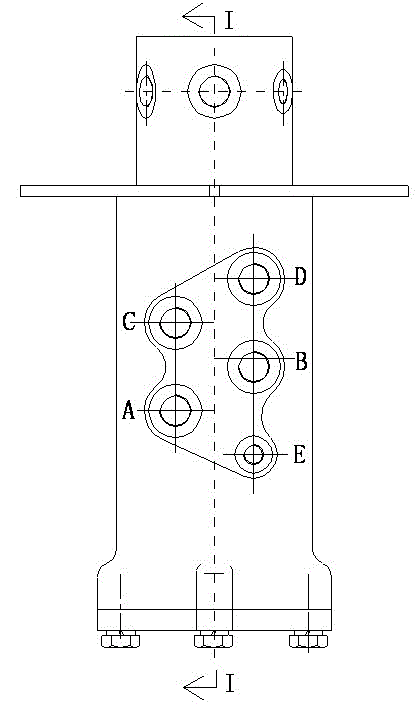

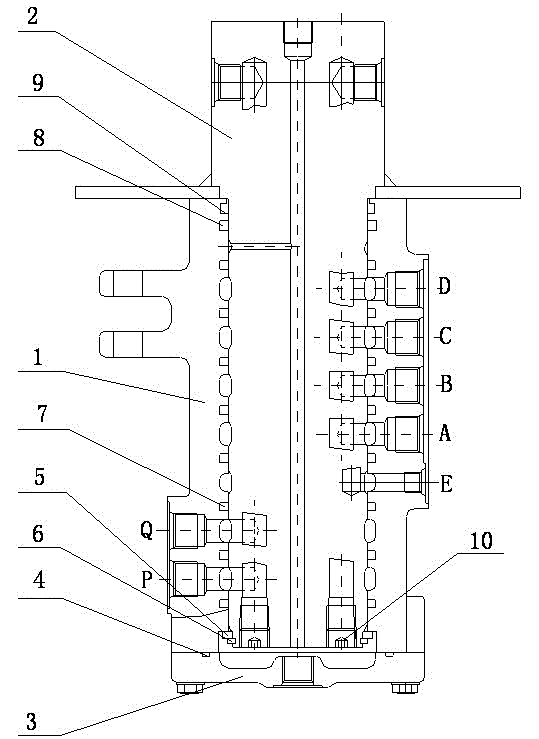

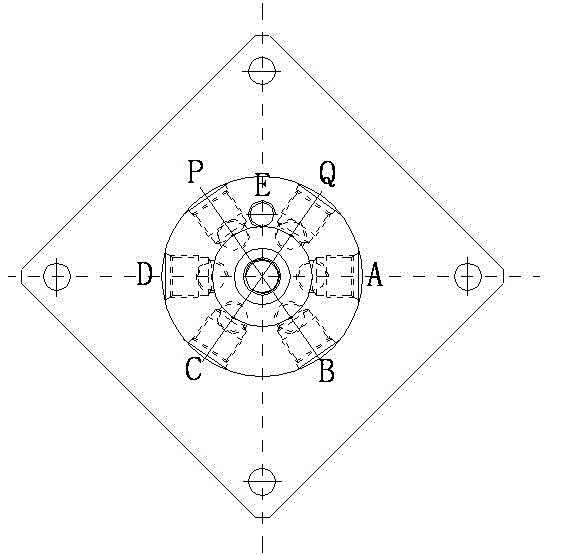

[0017] see Figure 1 to Figure 5 , the present invention relates to a rotary joint with a large rotary angle, comprising a rotary body 1 and a rotary shaft 2, the lower end of the rotary shaft 2 is axially inserted into the rotary body 1 from the upper end of the rotary body 1, and the upper end of the rotary shaft 2 is exposed In the revolving body 1, the lower end of the revolving body 1 is provided with an end cover 3, and the end cover 3 is fixed on the lower end of the revolving body 1 by bolts, and an O-shaped Ring I4, a retaining ring 5 and a shaft elastic retaining ring 6 are provided between the lower end of the rotary body 1 and the lower end of the rotary shaft 2, and a rotary seal is installed in the annular groove between the rotary body 1 and the rotary shaft 2 Ring 7, O-ring II 8 and dust-proof ring 9, the side of the dust-proof ring 9 in contact with the rotary shaft 2 is provided with two upper and lower lips 9.1 to form a double lip, and the upper and lower t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap