Goss N75 Printable Wide and Narrow Newspaper Transformation Method and Printable Wide and Narrow Newspaper Double-width Rotary Machine

A wide-narrow and Gaussian technology, which is applied in the transformation method of Goss N75 printable wide-narrow newspapers and the field of double-width rotary machines that can print wide-narrow newspapers, can solve problems such as difficult paper pressing, small horizontal spacing of triangle plates, loss of paper threading power, etc., and achieve cost Inexpensive, quick adjustment, less labor-consuming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

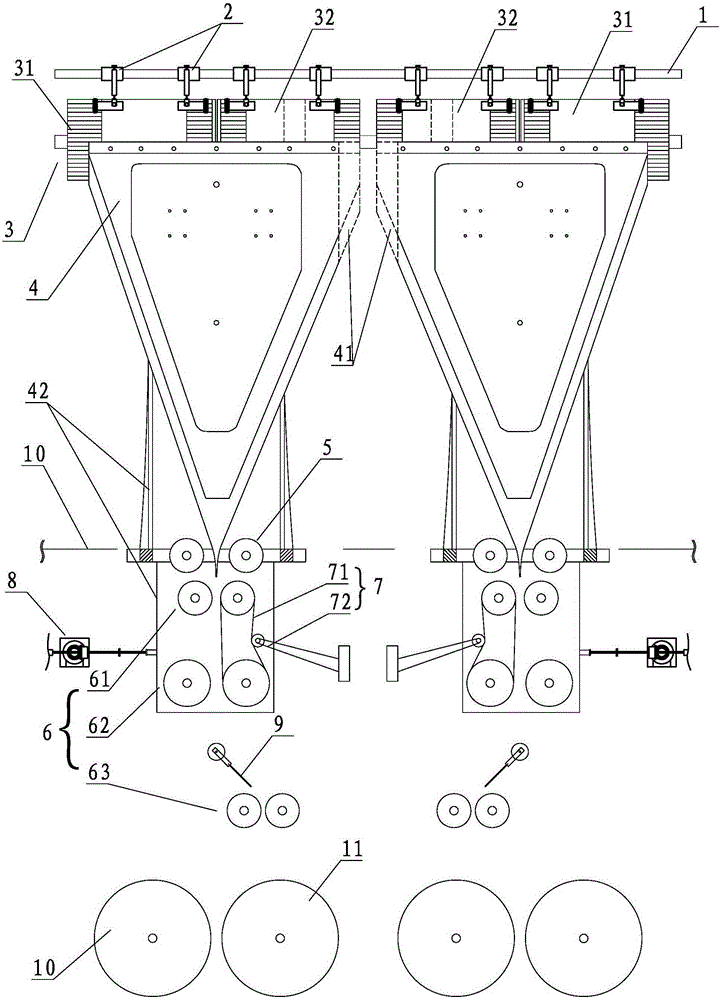

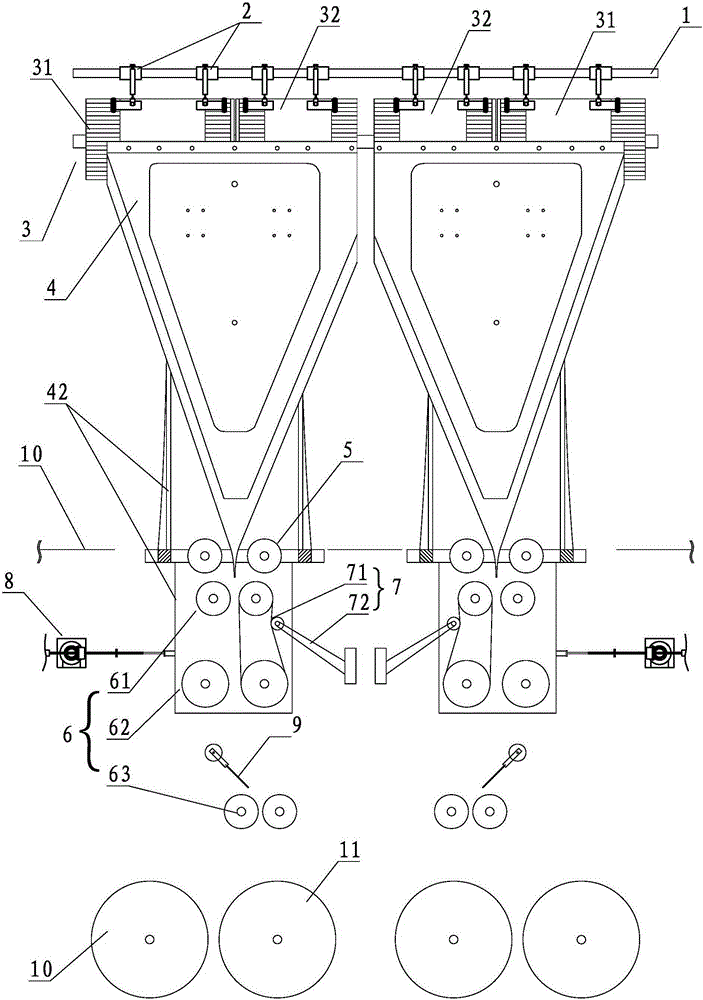

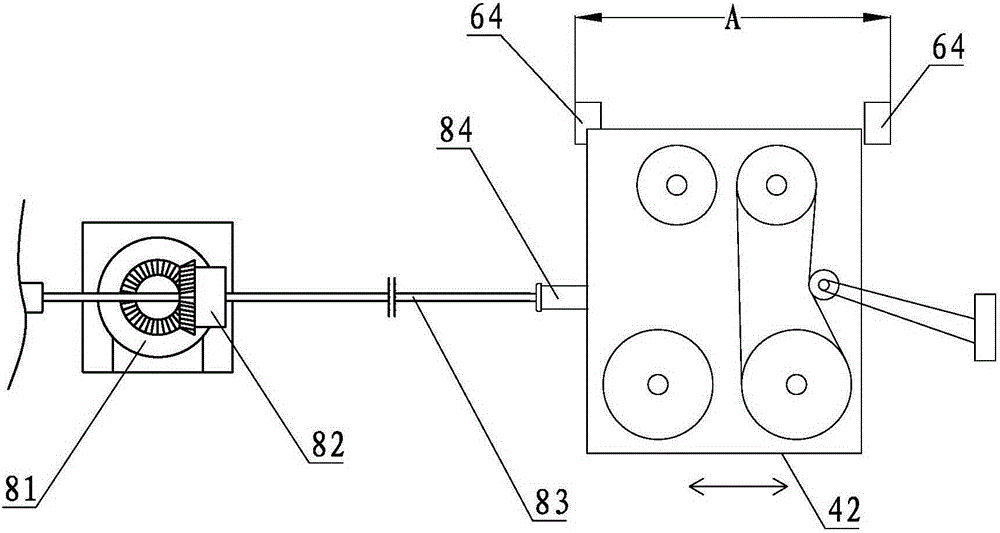

[0044] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0045] Aiming at the Goss N75 double-width rotary machine commonly used in the newspaper industry mentioned in the background technology, in order to make it adapt to the printing of wide and narrow newspapers with different widths, the present invention provides a transformation method for Goss N75 that can print wide and narrow newspapers, corresponding to Including transformation process and printing adjustment process two parts.

[0046] Among them, the most core Transformation process Specifically include:

[0047] According to the required amount of horizontal movement, the part of the adjacent corner of the two triangular plates is cut, so that the corner and the triangular plate become independent such as figure 1 The steps of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com