Acidic carboxymethylcellulose condensate treatment method

A technology of carboxymethyl cellulose and treatment methods, applied in chemical instruments and methods, wastewater treatment in processing, multi-stage water/sewage treatment, etc., can solve problems such as engineering application reports that have not been seen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

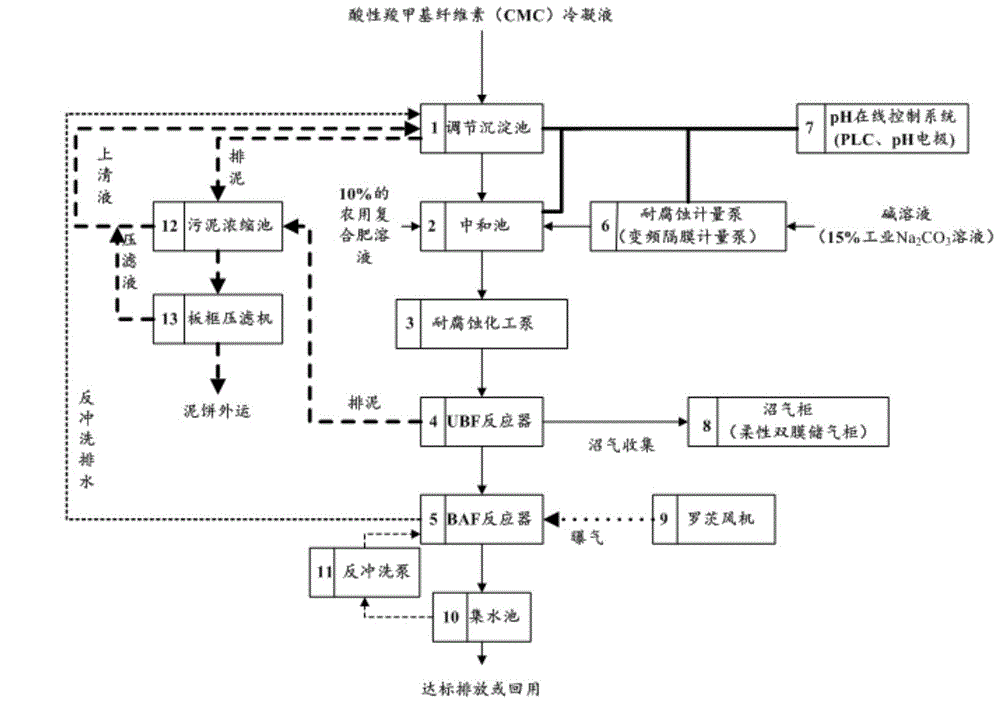

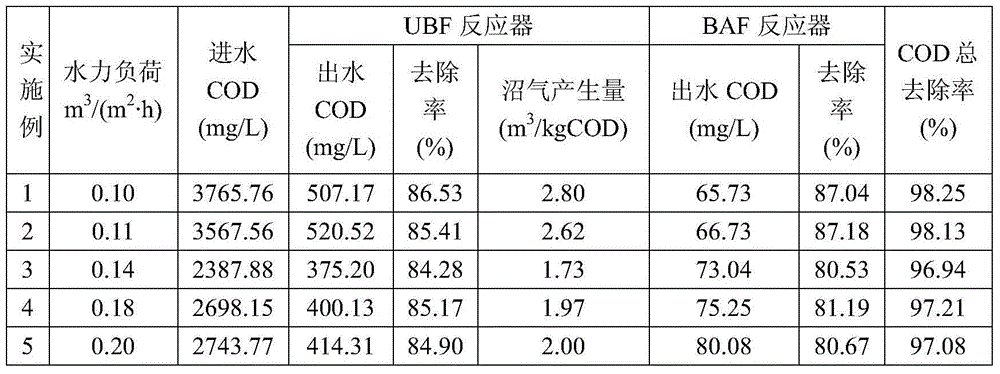

[0028] The acidic CMC condensate treatment process of the present invention first adopts UBF reactor anaerobic treatment, and then utilizes BAF aerobic treatment, and its process flow chart is as attached figure 1 shown. After the acidic CMC condensate enters the adjustment sedimentation tank 1 for homogenization and precipitation, it flows into the neutralization tank 2 by gravity, and industrial Na with a mass fraction of 15% is added to the tank. 2 CO 3 Alkaline solution, so that the pH value of the wastewater in the neutralization pool is stable between 6.5-7.5, and at the same time, a 10% agricultural compound fertilizer solution by mass is added dropwise. The wastewater stirred by the electric submersible mixer at the bottom of the neutralization tank is injected into the bottom of the UBF reactor 4 by the corrosion-resistant chemical pump 3, and the wastewater is anaerobically purified by the biofilm on the carrier in the reactor and flows into the BAF reactor 5 at the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com