Dry clutch friction plate assembly

A dry clutch and friction plate technology, applied in the field of clutches, can solve problems such as inconsistent operating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The following description is merely exemplary in nature and in no way intended to limit the invention, application, or use.

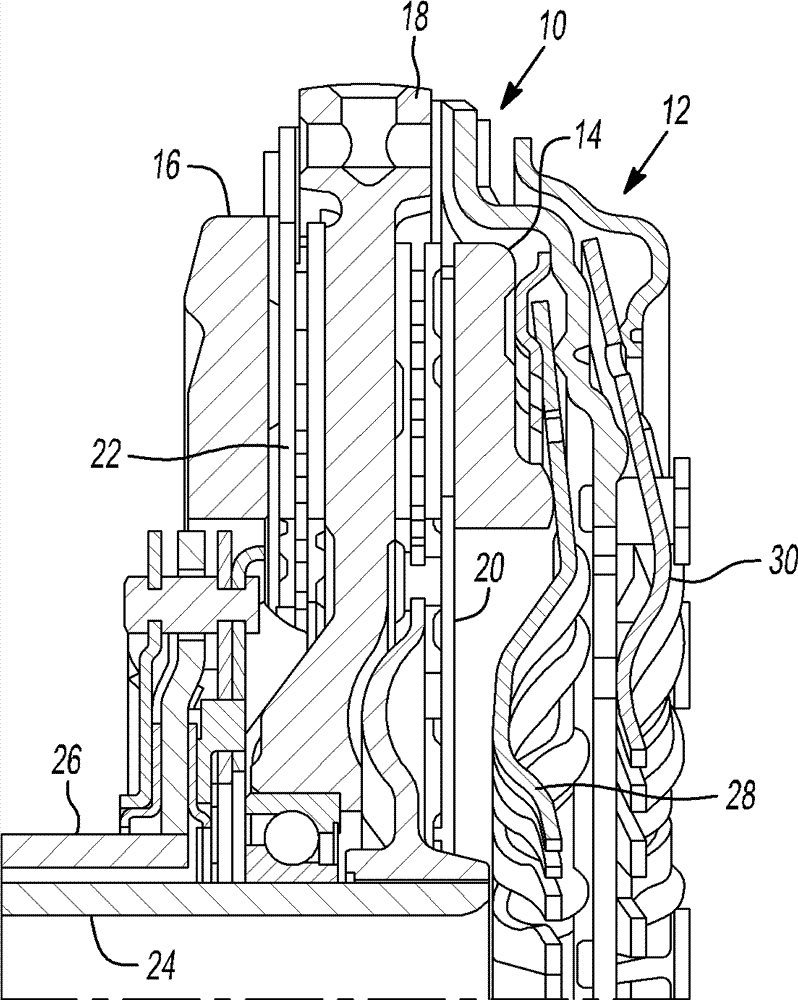

[0062] Referring to the drawings, wherein like reference numerals refer to like parts, in figure 1 In , a radial view of the dual clutch torque transmitting assembly 10 is illustrated and will now be described in accordance with an example of the present invention. The dual clutch torque transmitting assembly 10 includes an input assembly 12; first and second clutch apply members or plates 14, 16; a clutch support member 18, first and second clutch friction plate assemblies 20, 22 and first and second transmission input Members or shafts 24,26. The input assembly 12 is rotationally driven by, for example, a flywheel or other type of engine output member (not shown). The first and second clutch apply members 14 , 16 are in turn rotationally driven by the input assembly 12 and are axially movable via actuation of the first and second spring plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com