Three-phase woven fabric half-sleeved shirt with slide fastener

A braided fabric and short-sleeved technology, applied in the field of three-phase braided short-sleeved fabrics, can solve the problems of inability to produce a sense of layering, three-dimensional color, bursting, and difficulty in penetration, so as to increase the density and firmness, and the operation is simple , rich color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

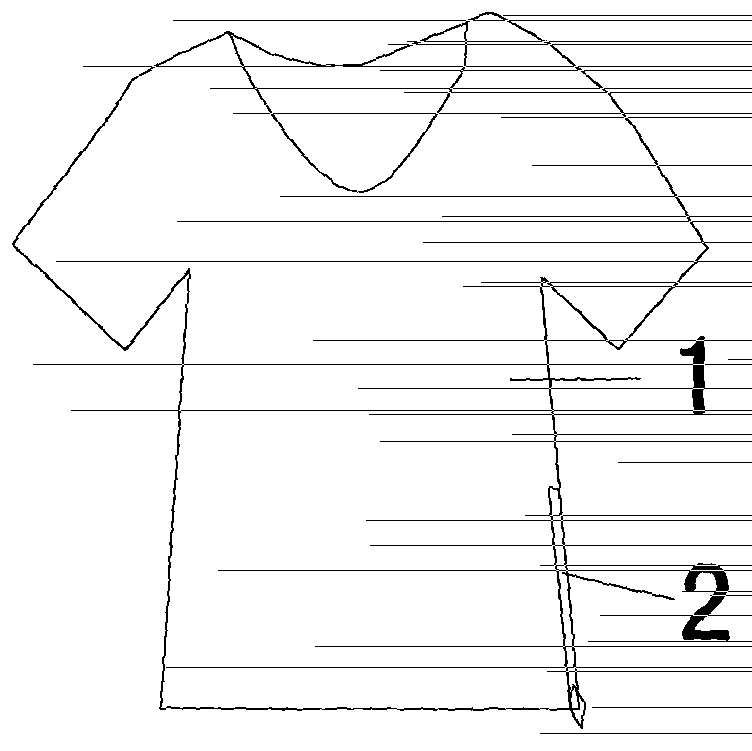

[0012] see figure 1 The present invention relates to a three-phase braided short sleeve with a zipper, comprising a short sleeve body 1, a section of zipper 2 is provided at the bottom of the short sleeve body 1, and the zipper 2 is arranged on the side of the short sleeve body 1 or At the back, the zipper 2 is opened from bottom to top. The short-sleeved body 1 is made of a three-phase braid, and the three-phase braid is formed by interweaving yarns, the yarns include weft yarns, and left-leaning warp yarns, right-leaning warp yarns, among the left-leaning warp yarns and right-leaning warp yarns, The law of weaving is: a weft yarn is passed under a left-leaning warp yarn to the adjacent right-leaning warp yarn, and then enters under the next left-leaning warp yarn, and weaves accordingly; The weft yarn passes under a right-leaning warp yarn to the next left-leaning warp yarn, and then enters under the next right-leaning warp yarn, and weaves accordingly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com