An integral reinforcement machine suitable for different beam-column structures

A technology of beam-column structure and reinforcement machine, which is applied in building structure, processing of building materials, construction, etc., can solve problems such as time-consuming, lack of responsibility of construction personnel, deviation of longitudinal main reinforcement of beam-column, etc., and achieve Reduce the infringement of the body, overcome the slow work efficiency, and install the adjustable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

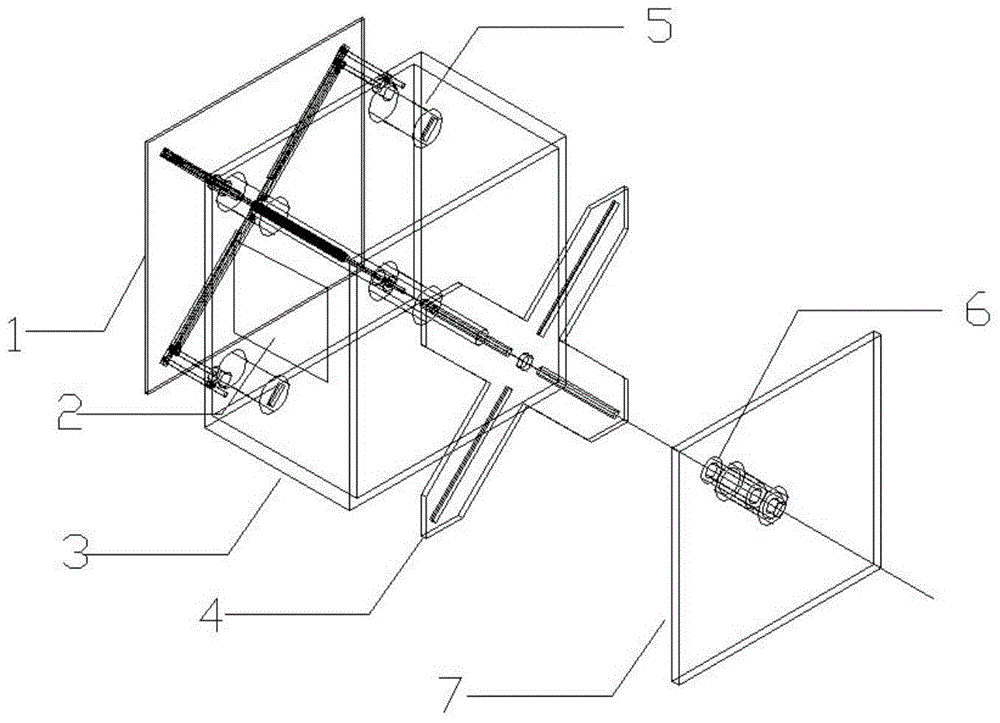

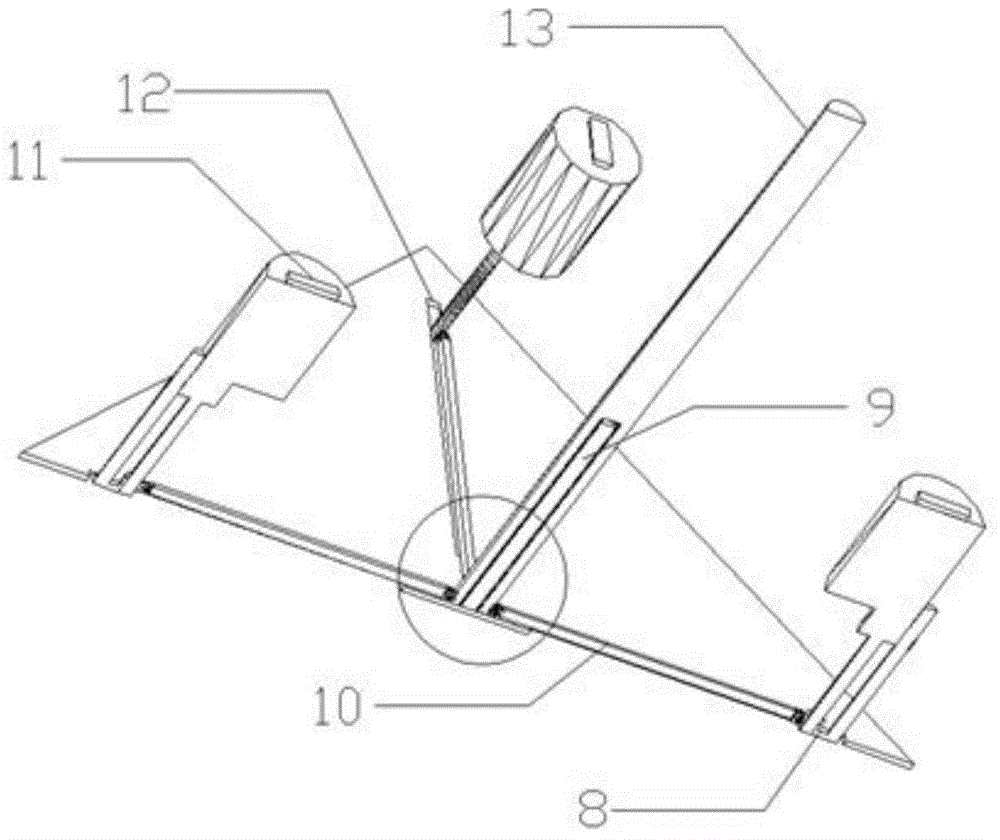

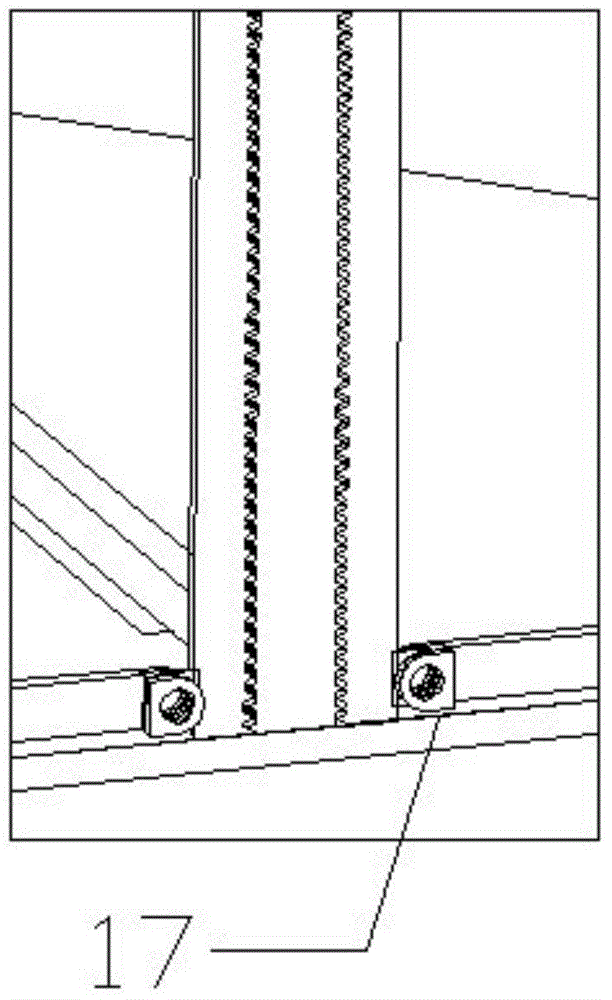

[0024] The overall reinforcement machine as shown in the accompanying drawings includes a machine cover 3, a force transmission plate 4, a through-hole jack 6 and a central axis screw 9, the bottom of the machine cover 3 is fixed to the base plate 1, and the upper part is covered by a cover plate 7. The central axis screw 9 is an outer thread bolt structure and is vertically fixed on the base plate 1, and is covered with an outer sleeve 13 through the outer thread; the base plate 1 has a No. 1 slide groove 12 with 4 equal parts centered on the central axis screw 9 , there are 4 locating parts 8 that are respectively stuck in the No. 1 sliding groove 12 that is divided into 4 equal parts. 14 matching annular structure, the positioning block 15 is stuck in the No. 1 sliding groove 12 for translational movement, and one end of the positioning hole 16 is a hinged connector 17, which corresponds to the outer sleeve 13 through the connecting rod 10. The hinge joint 17 is connected; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com