Molten steel dearsenication fluxing agent, and preparation method and application method thereof

A technology of arsenic removal and flux, applied in the field of metallurgy, can solve the problems of molten steel contaminated by arsenic removal products, corrosion of refractory materials, low efficiency of arsenic removal, etc., to improve stability and metallurgical effect, strong arsenic removal ability, and improve working environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] The present invention will be further elaborated below in conjunction with the examples; the examples are only used to illustrate the present invention, but not to limit the present invention in any way.

[0030] (1) Preparation of pre-melted arsenic-desorbing flux

[0031] The raw materials that embodiment adopts are as follows, and when referring to percentage below, be weight percent:

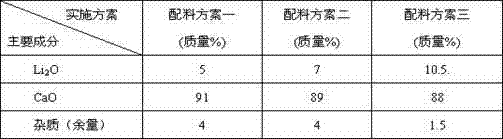

[0032] The chemical composition of active lime is: 100%>CaO≥90.0, 5%≥MgO>0, 2.5%≥SiO 2 >0, the rest are Al 2 o 3 and other trace impurities.

[0033] The chemical composition of industrial lithium oxide is: 100%>Li 2 O≥85.0, 8%≥SiO 2 >0,3%≥Al 2 o 3 >0, 2%>CaO≥0, the rest is Na 2 O and K 2 O and other trace impurities.

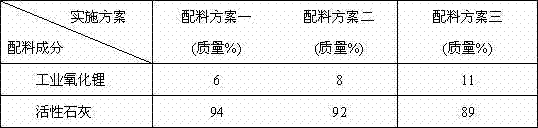

[0034] Take the above-mentioned raw materials and weigh them after baking at 200-250°C, and mix them according to the three batching methods in Table 1; break each raw material into 2mm or less, mix them mechanically, add them to a new ladle, and heat them ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com