Method for resuming operation of wire saw and wire saw

一种再次开始、运转方法的技术,应用在锯床的附属装置、金属锯切设备、精细的工作装置等方向,能够解决无法修正阶梯差等问题,达到抑制纳米形貌的恶化、防止成为不良的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 3)

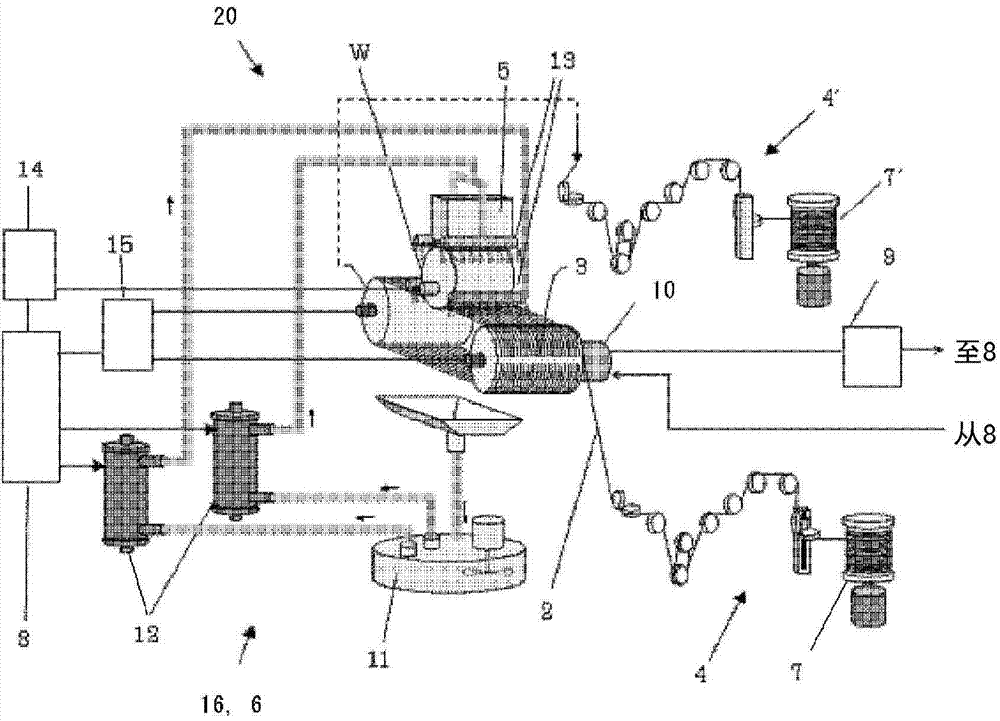

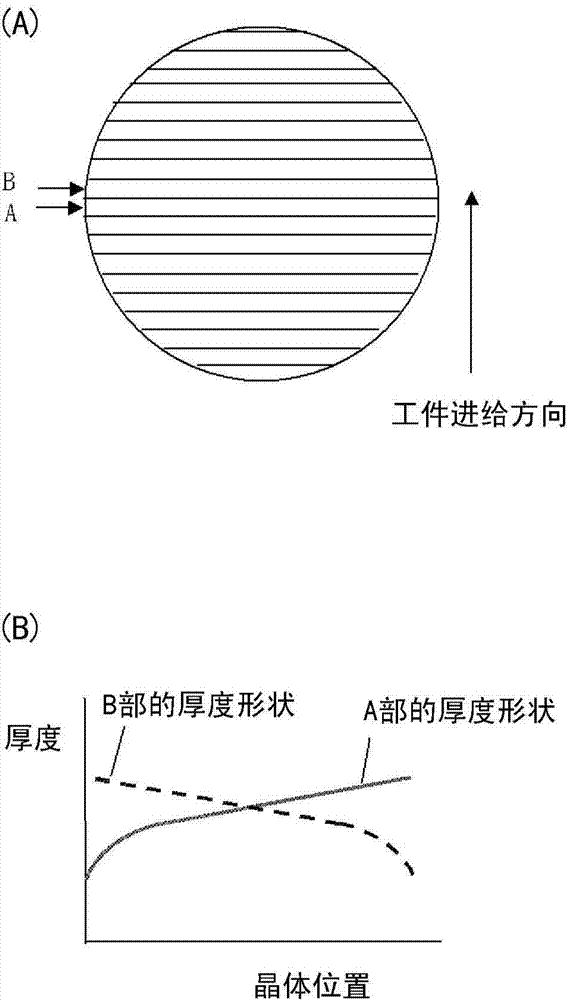

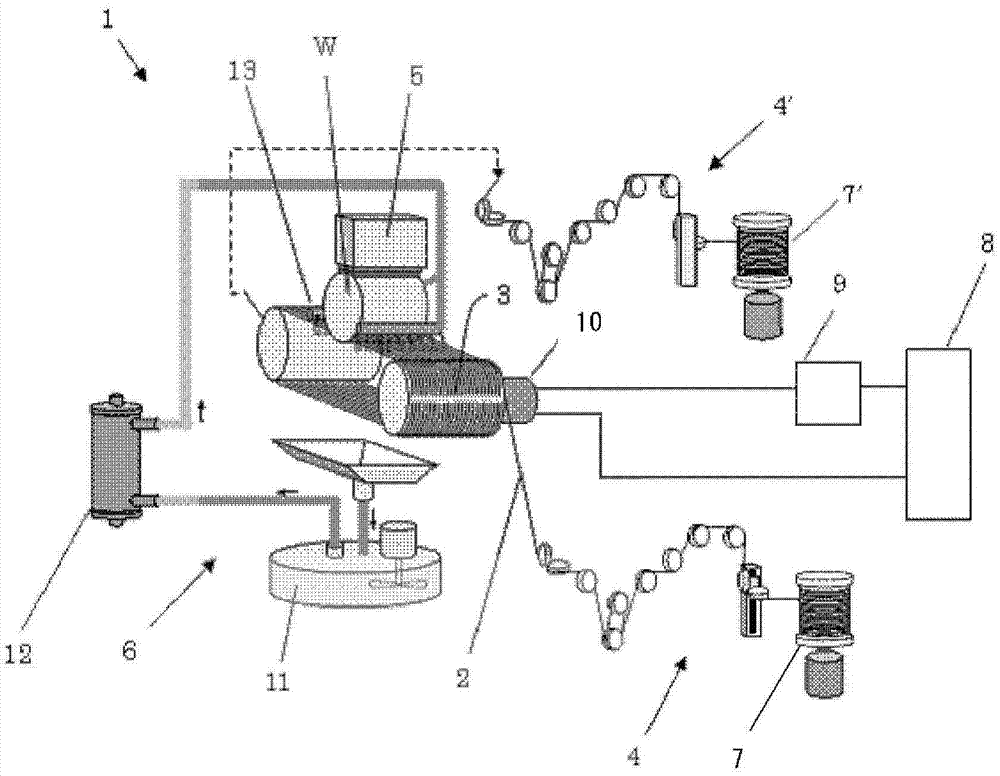

[0076] Use as figure 1 The wire saw of the present invention shown starts cutting a silicon ingot with a diameter of 300 mm into a wafer shape, interrupts the cutting in the middle of the cutting, and restarts the cutting by the restarting operation method of the present invention. Then, the nano-topography of the cut wafer was evaluated. Here, the maximum value of the nano-topography in the range of 10 mm×10 mm measured in the range near the cutting interruption position was evaluated.

[0077] In addition, in the cutting of the workpiece, the steel wire is Figure 4 The travel speed curve shown travels. This travel speed curve has the following travel cycle: starting from the time point represented by 0, the steel wire is moved in the forward direction, at the time point represented by B, decelerating with a prescribed acceleration, and starting at the time point represented by B′ Make the steel wire travel in the backward direction.

[0078] First, while detecting and recordi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap