Wireless remote control comprehensive hole measuring robot for rock mass engineering

A wireless remote control and robot technology, applied in the field of geotechnical engineering, can solve the problems of threats to the life safety of operators, large energy and time consumption, and danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

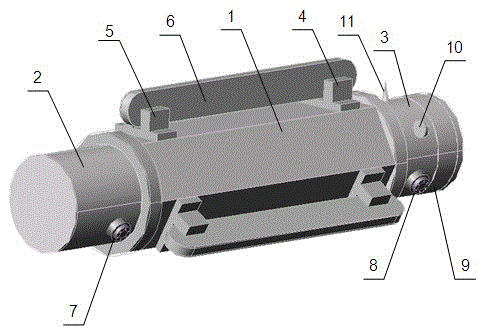

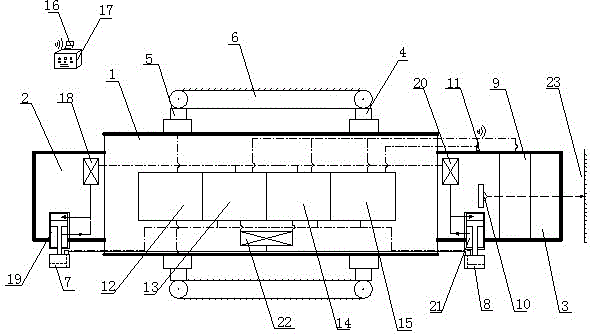

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0016] see Attachment

[0017] A wireless remote control comprehensive hole measuring robot for rock mass engineering. The hole measuring robot consists of a carrying platform 1, a front carrying cabin 3, a rear carrying cabin 2, a battery 13, a drive system, a data acquisition system 15, a sound wave testing system, and a digital drilling camera. 9. Laser rangefinder 10, internal control system 14, external control system 16, transmission antenna 11, and data receiving platform 17. The carrying platform 1 is in the shape of a regular hexagonal prism. The front carrying cabin 3 and the rear carrying cabin 2 are respectively located on the carrying platform 1. The front end and the rear end, the front loading cabin 3 and the rear loading cabin 2 are all cylindrical, and the drive system is composed of a rear base 5, a front base 4, a crawler belt 6, and a step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com