A kind of repair method of thermoplastic honeycomb panel

A repair method and thermoplastic technology, applied in the field of composite materials, can solve the problems of damage of thermoplastic honeycomb composite panels, poor mechanical strength of plates, obvious repair marks, etc., and achieve the effects of fast repair speed, high firmness and good visual effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

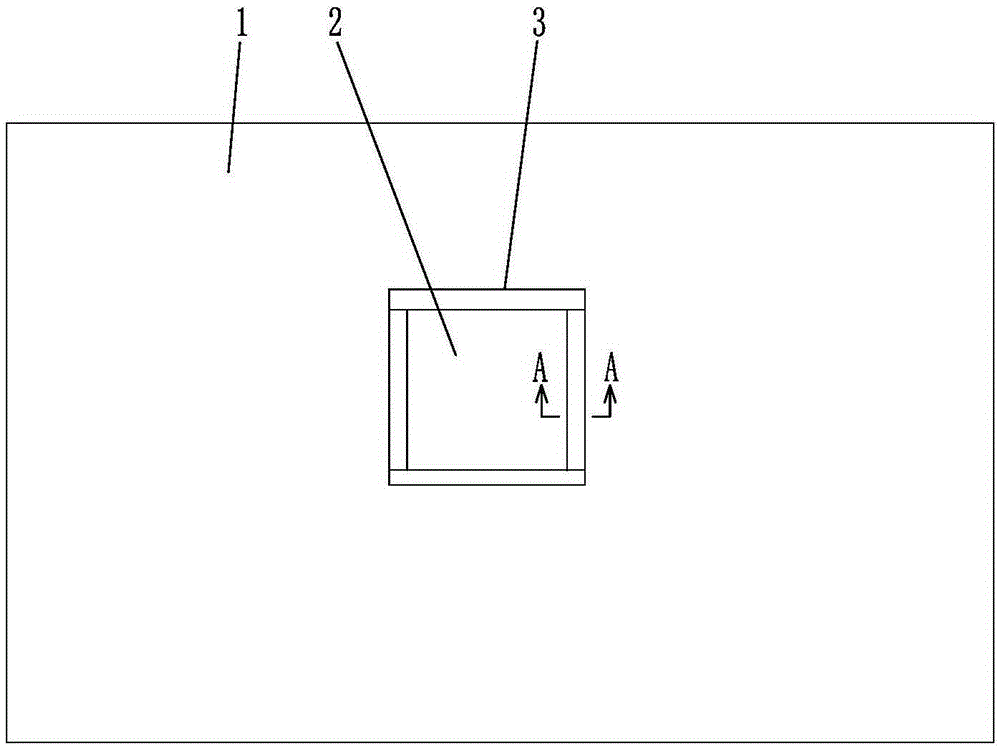

[0021] A method for repairing a thermoplastic honeycomb panel, comprising the steps of:

[0022] 1) Positioning: When a piece of thermoplastic honeycomb composite panel A is partially damaged, according to the size and shape of the damage, enlarge the damaged area and draw a line to form an auxiliary identification area;

[0023] 2) Sawing: use a cutting tool to cut through the thermoplastic honeycomb composite panel from the entrance of the scribed line, and cut off the entire auxiliary marking area to form a gap;

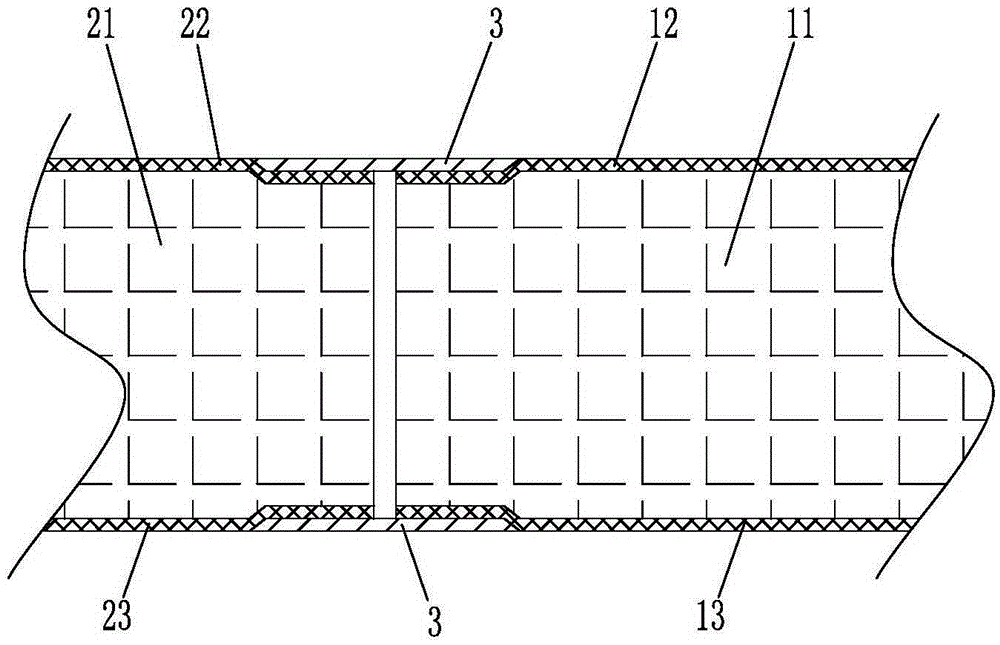

[0024] 3) Filling: Cut the thermoplastic honeycomb composite board B with a cutting tool to cut out a filling board of the same shape and size as the gap of the thermoplastic honeycomb composite board A, put the filling board into the gap of the thermoplastic honeycomb composite board A, and place it smooth;

[0025] 4) Flat ironing: choose glass fiber reinforced polypropylene surface material with a thickness of 0.5-1.0mm and a width of 30-70mm; ℃), the surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com