Cap feeding apparatus and method

A technology of a supply device and a filling machine, which is applied in the field of cap supply, can solve the problems of easy failure, additional cost, damaged caps, etc., and achieves the effect of less failure and less maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

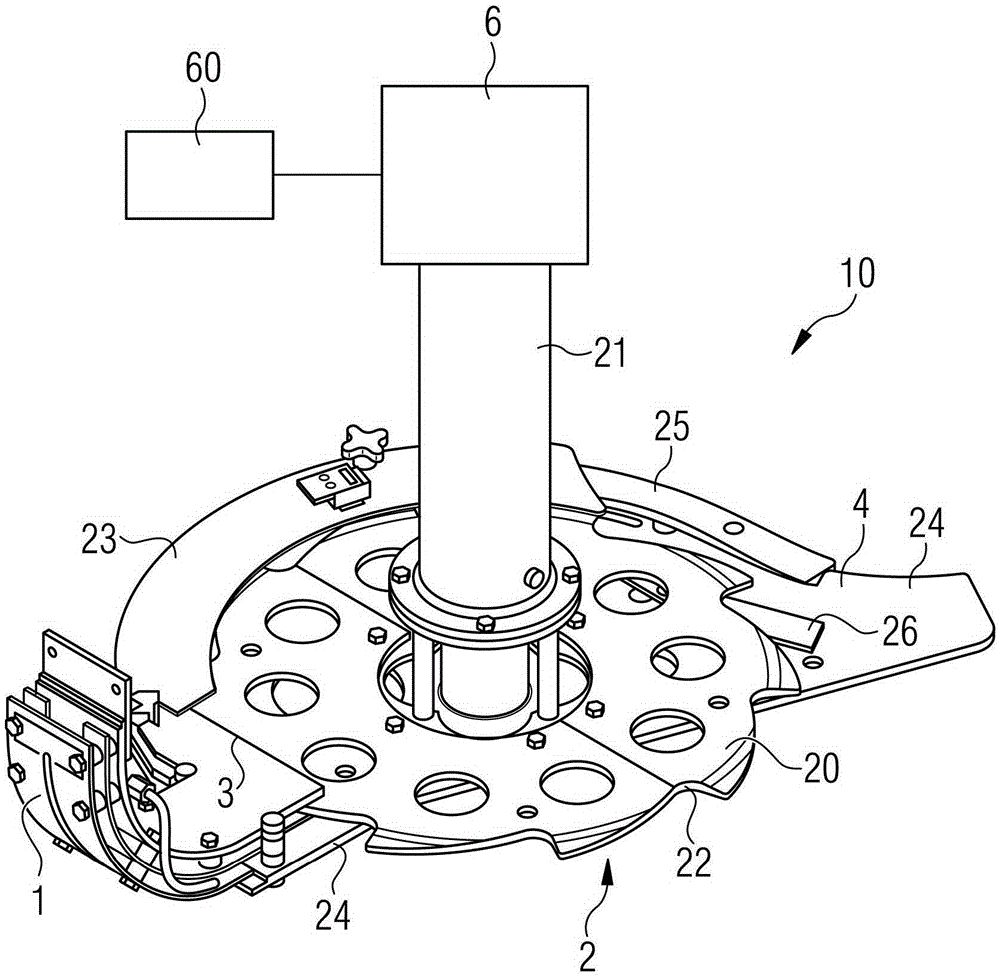

[0041] Preferred embodiments are described below in conjunction with the accompanying drawings. Here, identical, similar or identically acting elements are identified with the same reference numerals and a repeated description of these elements is omitted in the following description in order to avoid redundancy.

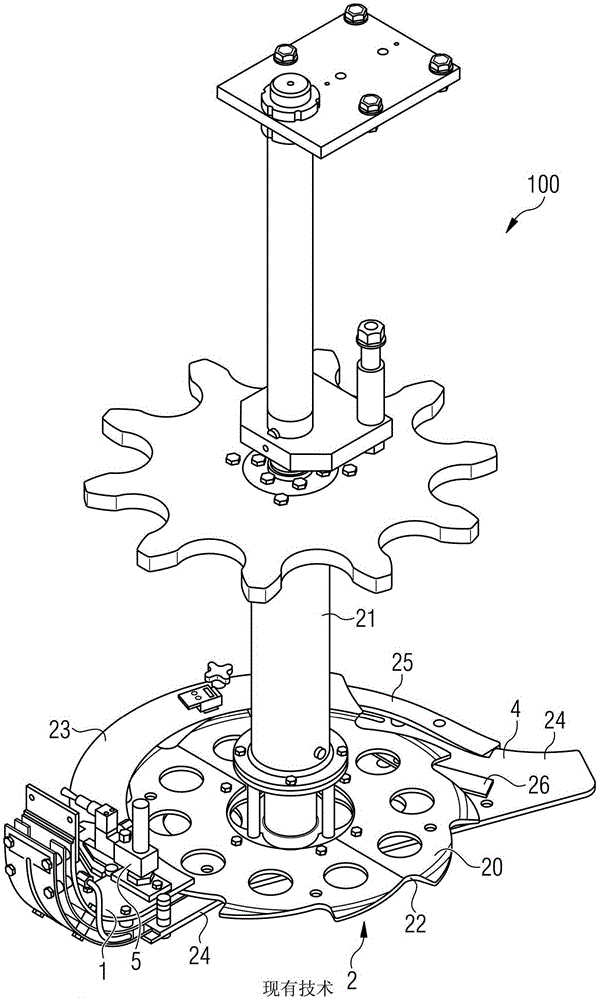

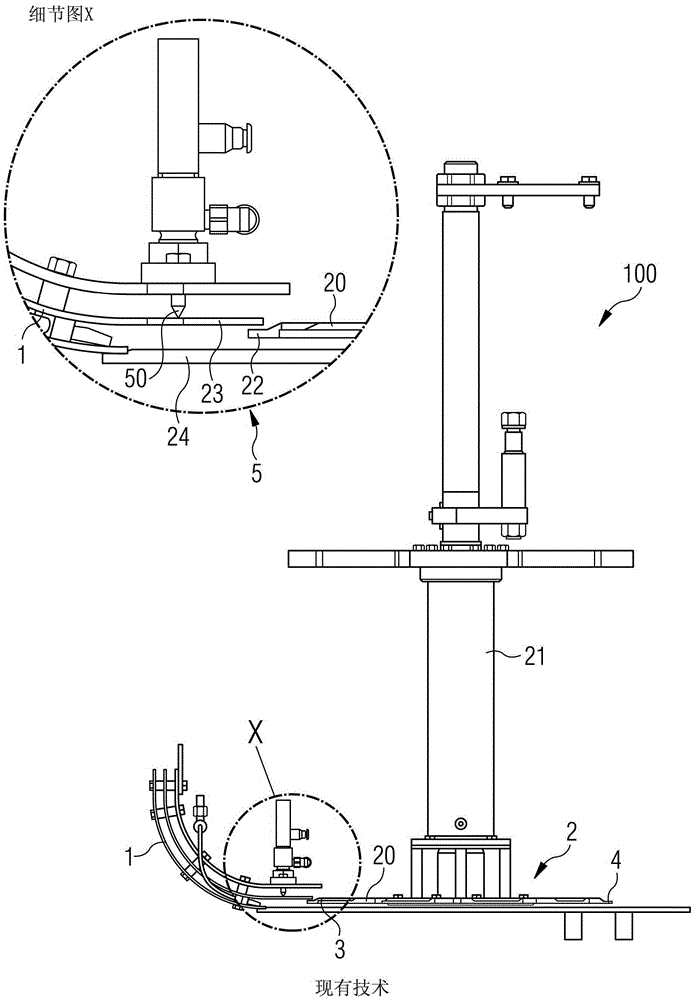

[0042] figure 1 A device 100 according to the prior art is shown schematically in a perspective view for supplying caps not shown here. figure 2 A schematic side view of the device 100 according to the prior art is shown.

[0043] figure 1 and figure 2 The illustrated cap supply device 100 comprises a supply unit 1 for continuously supplying caps to a take-up wheel 2 . The supply unit 1 is designed as a cap supply chute, through which a certain stagnation pressure is brought to the caps, and then the caps are supplied to the receiving wheel 2 .

[0044] The take-up wheel 2 has a disc-shaped body 20 and is driven by a drive shaft 21 . On the periphery of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com