Device and method for implementing and monitoring a laser transmission welding process of plastics

A laser transmission welding and process technology, applied in laser welding equipment, measuring devices, welding equipment, etc., can solve the problem of workpiece rejection, no more detailed description of the welding seam, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

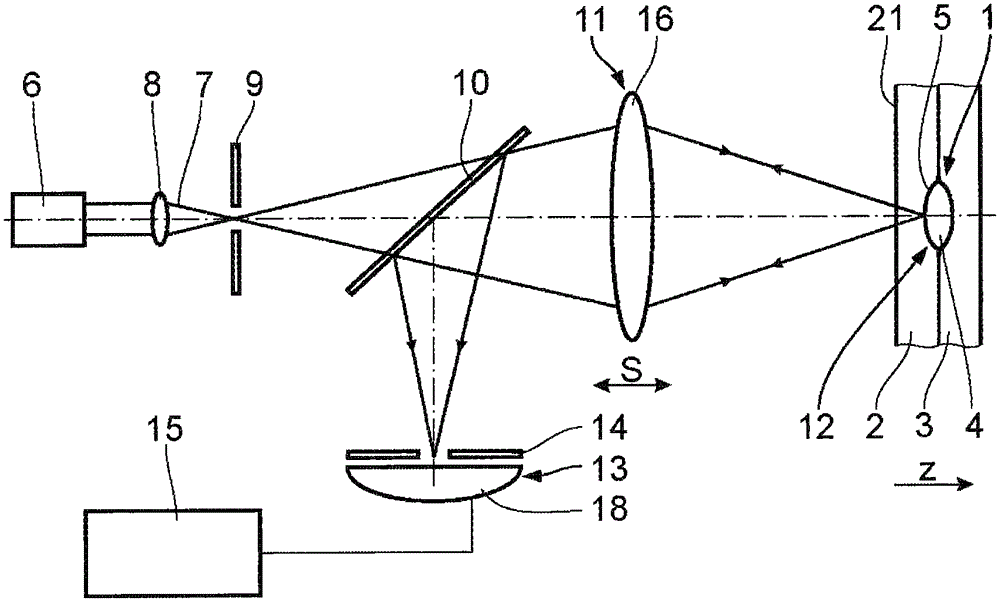

[0024] figure 1 A first embodiment of a device for carrying out and monitoring a plastic laser transmission welding process is shown. The process beam source for generating and emitting a laser beam which is used as a process beam entering the joining region 1 of the two joining elements 2, 3 is not shown in more detail, since it corresponds to the Process beam source used in traditional laser transmission welding. The process beam source is used to form a weld seam 4 between two joining elements 2, 3, as in the figure 1 Between the two joining elements 2, 3 is shown in a cross-sectional view.

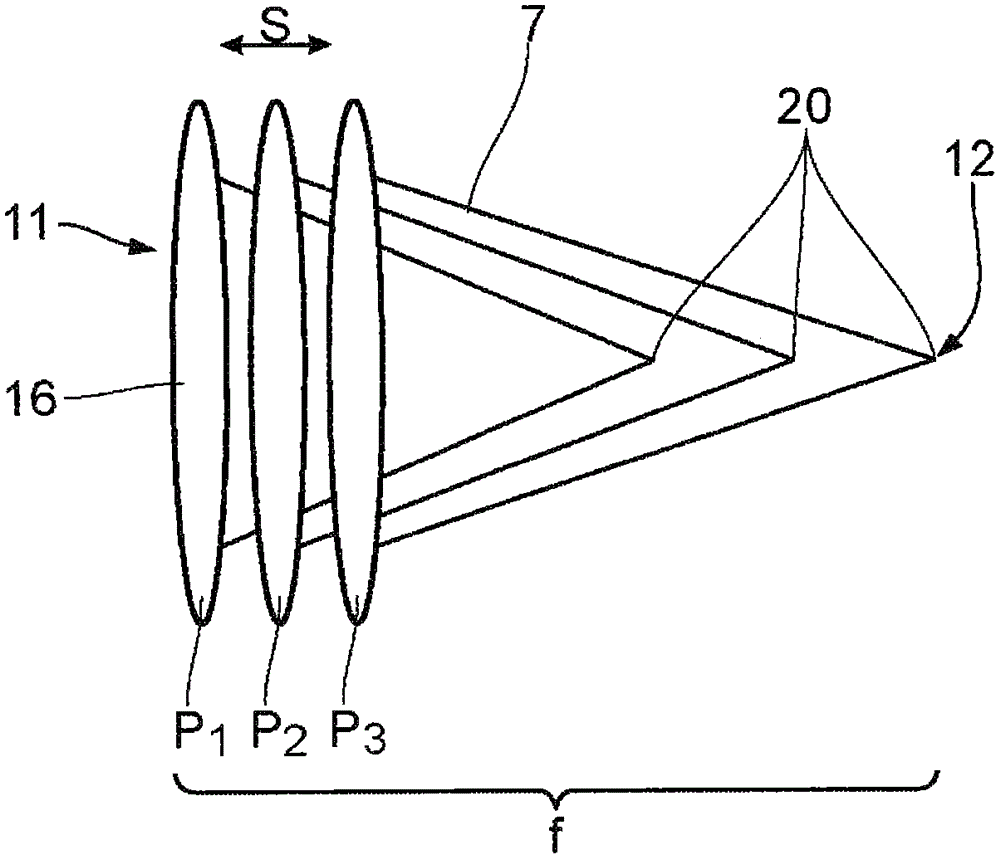

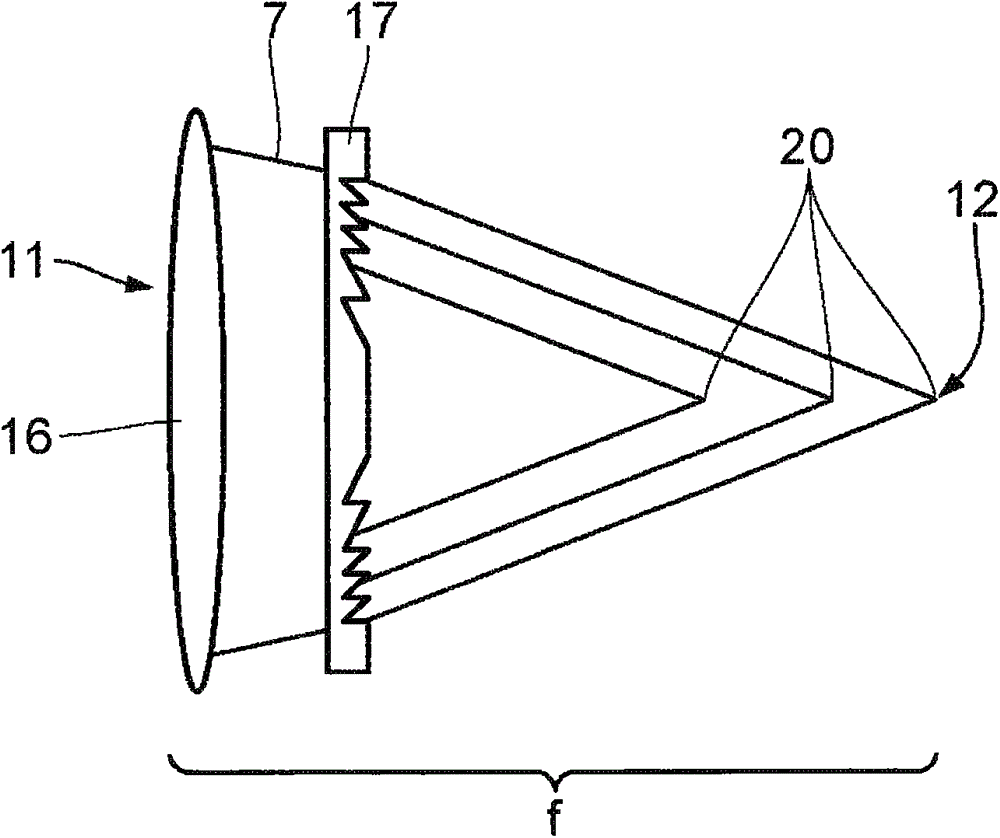

[0025] In order to determine the depth position of the interface 5 between the weld seam 4 and the joining elements 2, 3, in other words for welding depth monitoring in the corresponding laser transmission welding process, a measuring beam source 6 in the form of a point light source is provided, which The measuring beam 7 is processed by a lens 8 and an aperture 9 to obtain a focus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com