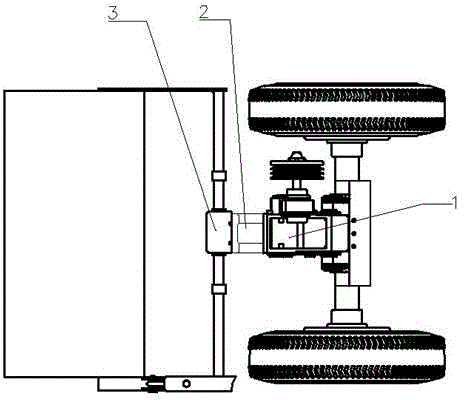

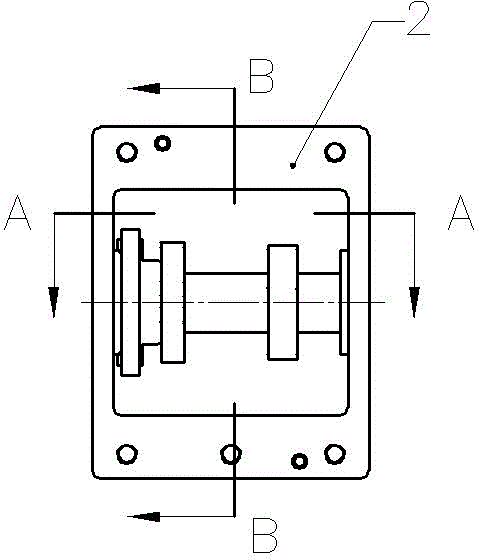

Rotary tillage part and carriage connection device

A technology for connecting devices and chassis, applied in the fields of tillage equipment, applications, agricultural machinery and implements, etc., can solve the problems that the rotary tillage components affect the efficiency of rotary tillage operations and the effect of rotary tillage operations, etc., so as to improve the efficiency of rotary tillage operations and improve the Rotary tillage effect, the effect of eliminating wheel marks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

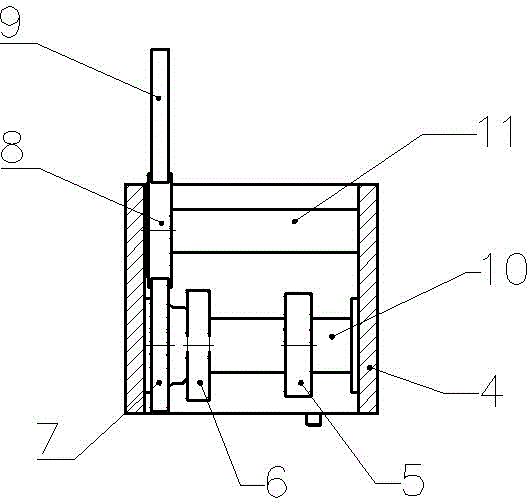

[0024] Make the distance between rotary tillage part 3 and chassis 1 longer by 150mm, then the center distance between E gear 9 and B gear 7 is 150mm, E gear 9, A gear 8 and B gear 7 are on the same straight line, E gear 9 and B gear 7 The diameter of the indexing circle is 81mm. According to the tangential design of the indexing circle of the external meshing gear, the diameter of the indexing circle of gear A 8 is 69mm. According to the equal modulus of the meshing gears, the modulus of the gears is 3. Therefore, The parameters of A gear 8: M=3; Z=23, α=20° (standard cylindrical spur gear).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com