Easy-to-adjust multi-rotary universal rotary tiller

A general-purpose, rotary tiller technology, applied in the field of agricultural machinery, can solve the problems of not realizing the reversal of the rotary tiller machete, the inability of the blade to enter the soil, and the complex structure of the transmission device, so as to improve the efficiency of rotary tillage operations, simplify the structure, The effect of reducing renovation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

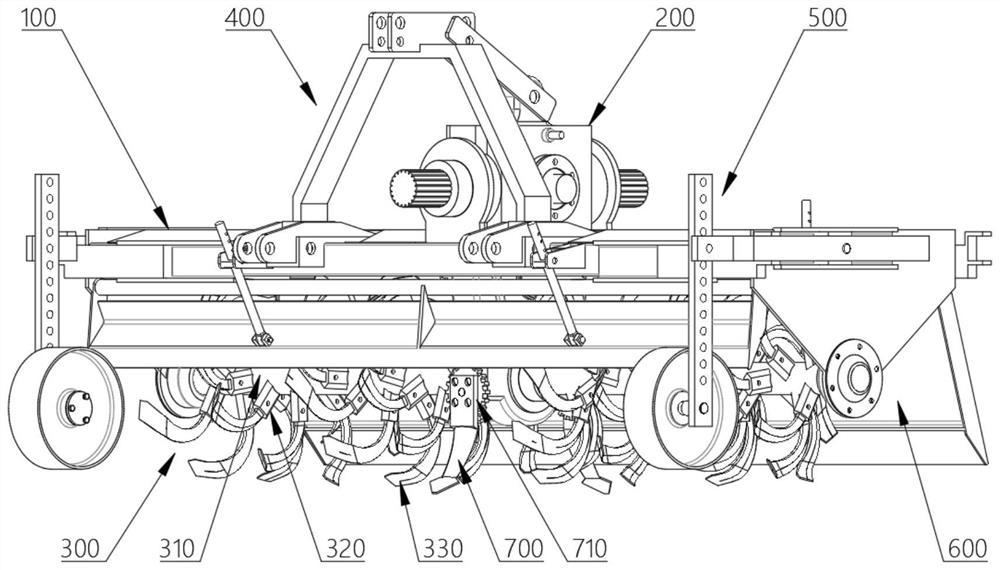

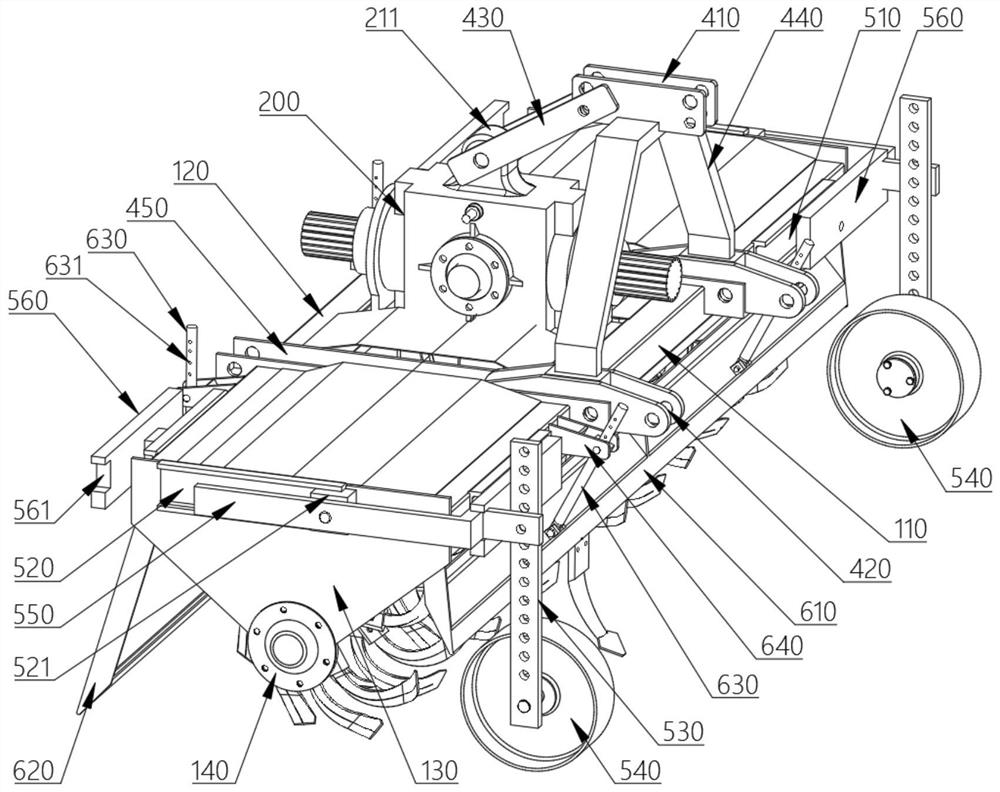

[0044] Such as Figure 1-8 As shown, the easy-to-adjust multi-rotation universal rotary tiller designed in this embodiment includes a frame 100, a gearbox 200 and a knife roller 300, wherein:

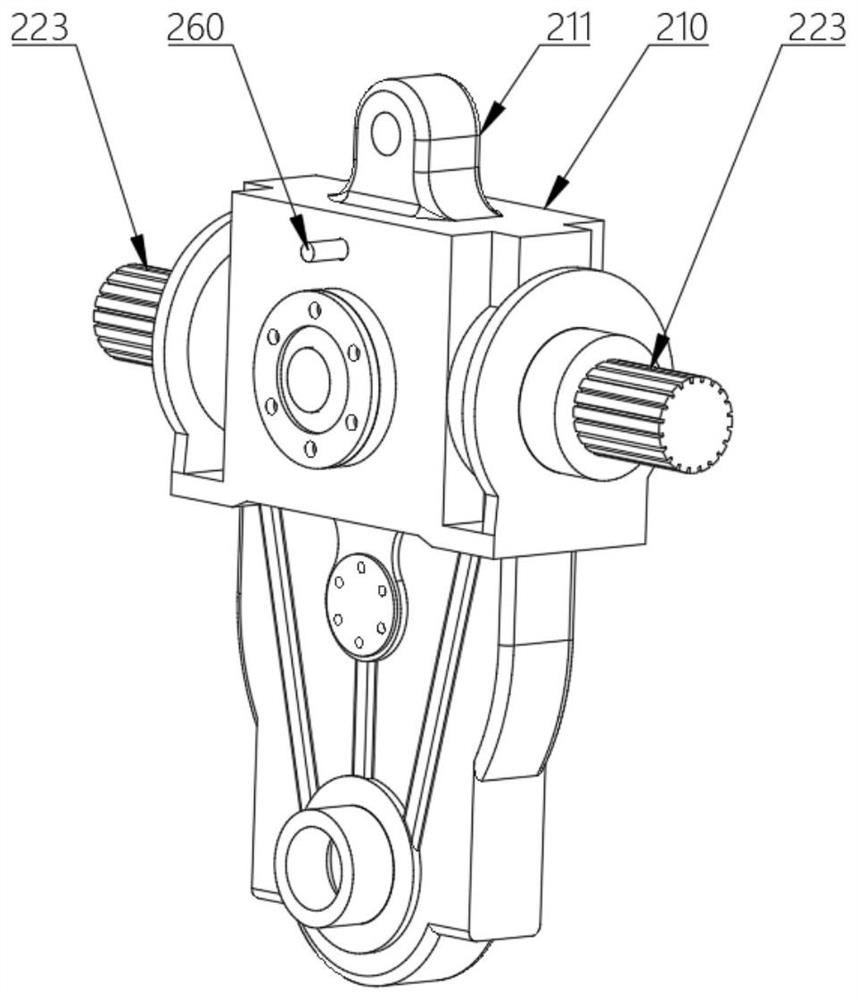

[0045] Such as image 3 , Figure 4 As shown, the gearbox 200 includes a gearbox housing 210 , a bevel gear train 220 and a spur gear train 230 .

[0046] The bevel gear train 220 includes two identical small bevel gears 221 and two identical large bevel gears 222; the two small bevel gears 221 are respectively mounted on the front and rear sides of the gearbox housing 210 through a small bevel gear shaft 223 ; Two large bevel gears 222 are installed on the left and right sides of the gearbox housing 210 through a large bevel gear shaft 224 respectively; each small bevel gear 221 meshes with two large bevel gears 222 simultaneously, and each large bevel gear 222 simultaneously Meshes with two small bevel gears 221 .

[0047] The spur gear train 230 includes a small spur gear 231 , a...

Embodiment 2

[0065] This embodiment describes the operation mode and power transmission method of the easy-to-adjust multi-rotation general-purpose rotary cultivator (using an asymmetric rotary cultivator roller) provided in Embodiment 1.

[0066] Operation mode one: such as Figure 9 In the power transmission mode shown, the surface of the frame 100A is connected to the power output shaft of the tractor through a universal joint. At this time, the front fender 610 is in the folded state, and the rear fender 620 is in the extended state. The position changes the depth depth of the depth gauge wheel 540 and connects the two half-clutches of the first clutch 240 through the operating mechanism 260 . At this time, the direction of rotation is as Figure 13 As shown by the arrow in the middle line, the asymmetric structure of the rotary tiller roller 300 is adopted, and the tangential cutting edge of the rotary tiller 330 is close to the ground surface during operation, and the normal rotatio...

Embodiment 3

[0071] This embodiment describes the operation process of the easy-to-adjust multi-rotation general-purpose rotary cultivator (using a double-sided symmetrical rotary cultivator roller) provided in Embodiment 1. The operation mode of this embodiment is exactly the same as that of Embodiment 2, and the difference is only in the type of the rotary blade roller 300 .

[0072] when using Figure 9 In the power transmission mode shown, the status of the rotary tiller is as follows Figure 15 As shown, the rotation direction is shown by the solid arrow in the figure, and the forward rotation operation is performed (that is, the rotation direction is the same as that of the tractor wheel, the same below).

[0073] when using as Figure 10 In the power transmission mode shown, the status of the rotary tiller is as follows Figure 16 As shown, the rotation direction is shown by the solid arrow in the figure, and the anti-rotation operation is performed (that is, the rotation directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com