An automatic tracking lighting system

A lighting system and automatic tracking technology, which is applied in the field of lighting systems, can solve the problems that lighting equipment cannot move equipment operating parts, affect work efficiency, and poor lighting effects, etc., and achieve good lighting effects, simple structure, and concentrated lighting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

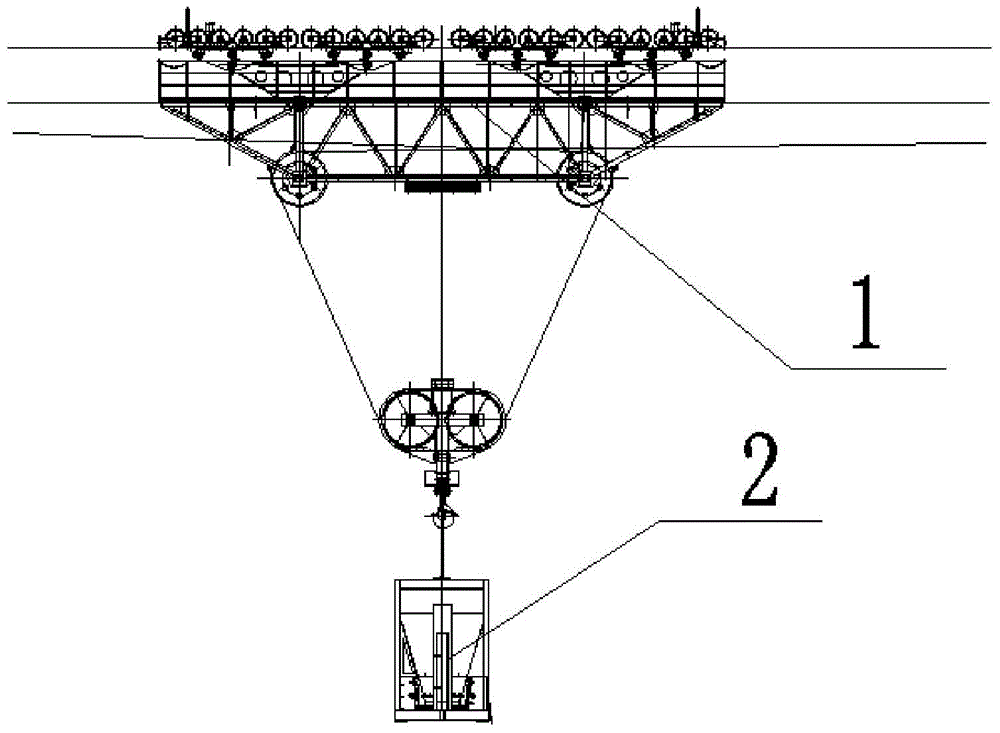

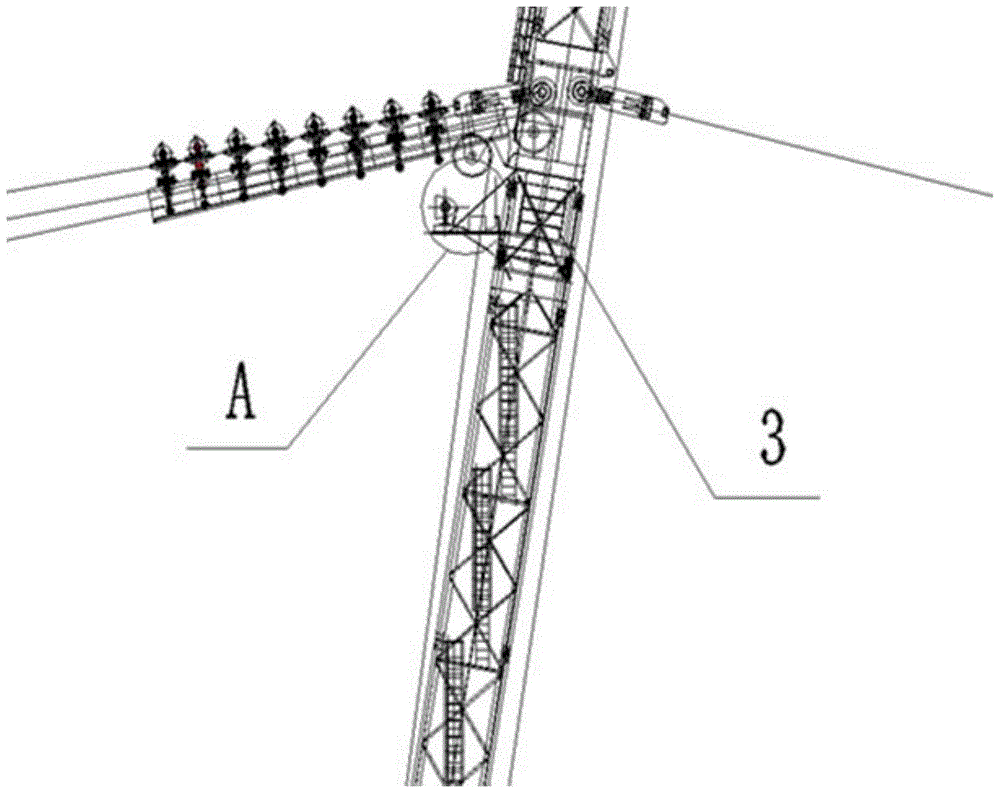

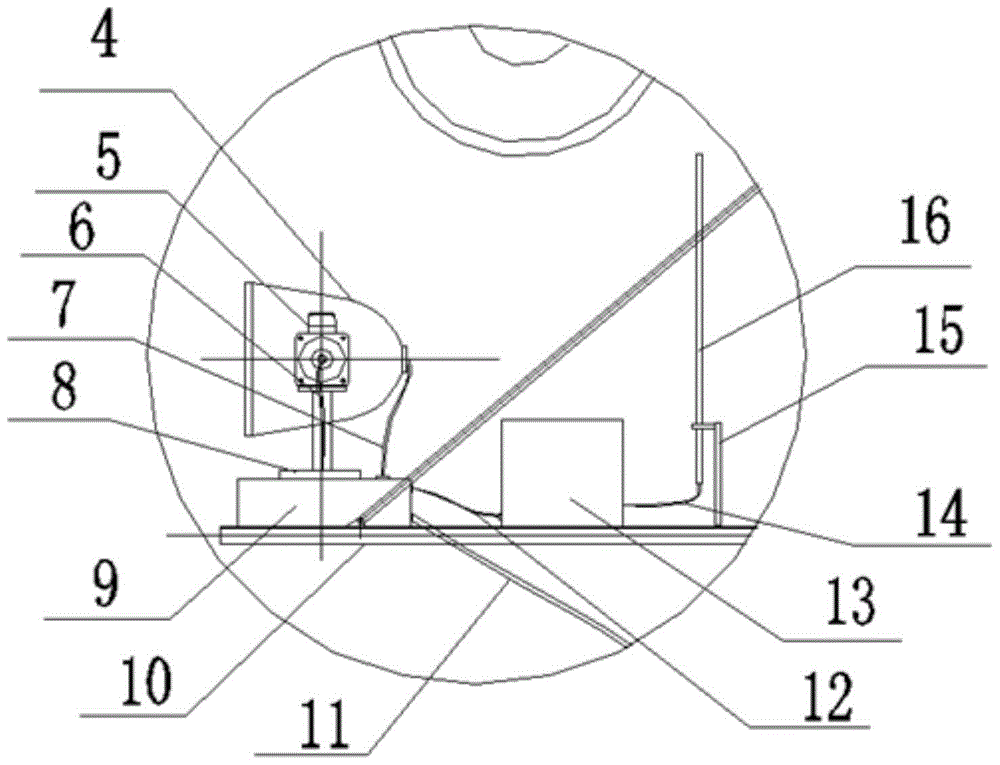

[0033] like Figure 1~4 As shown, the automatic tracking lighting system of the present invention includes an execution unit, and the execution unit includes a support platform 10 . A searchlight 4 is arranged on the support platform 10 , and a driving mechanism for driving the searchlight 4 is arranged on the searchlight 4 . The driving mechanism includes a pitching mechanism 5 and a horizontal rotary platform 8 that are all connected to the searchlight 4. The pitching mechanism 5 can drive the searchlight 4 to perform a pitching action, and the horizontal rotary platform 8 can control the searchlight 4 to perform a horizontal motion. turn.

[0034] The system data control box 13 for controlling the pitch mechanism 5 and the horizontal rotary platform 8 is also provided on the support platform 10. The present invention can use an external power supply or a storage battery as the system data control box 13, the searchlight 4, and the pitch mechanism. 5 and horizontal rotary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com