Giant engineering tire forming drum

A technology for engineering tires and forming drums, applied in the field of material forming, can solve the problems of damage to tire forming quality, lower tire forming quality, large axial movement size of the auxiliary core of the forming drum, etc., so as to avoid tangential extrusion of tire blanks. , Excellent molding quality of tire blanks, and the effect of improving molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

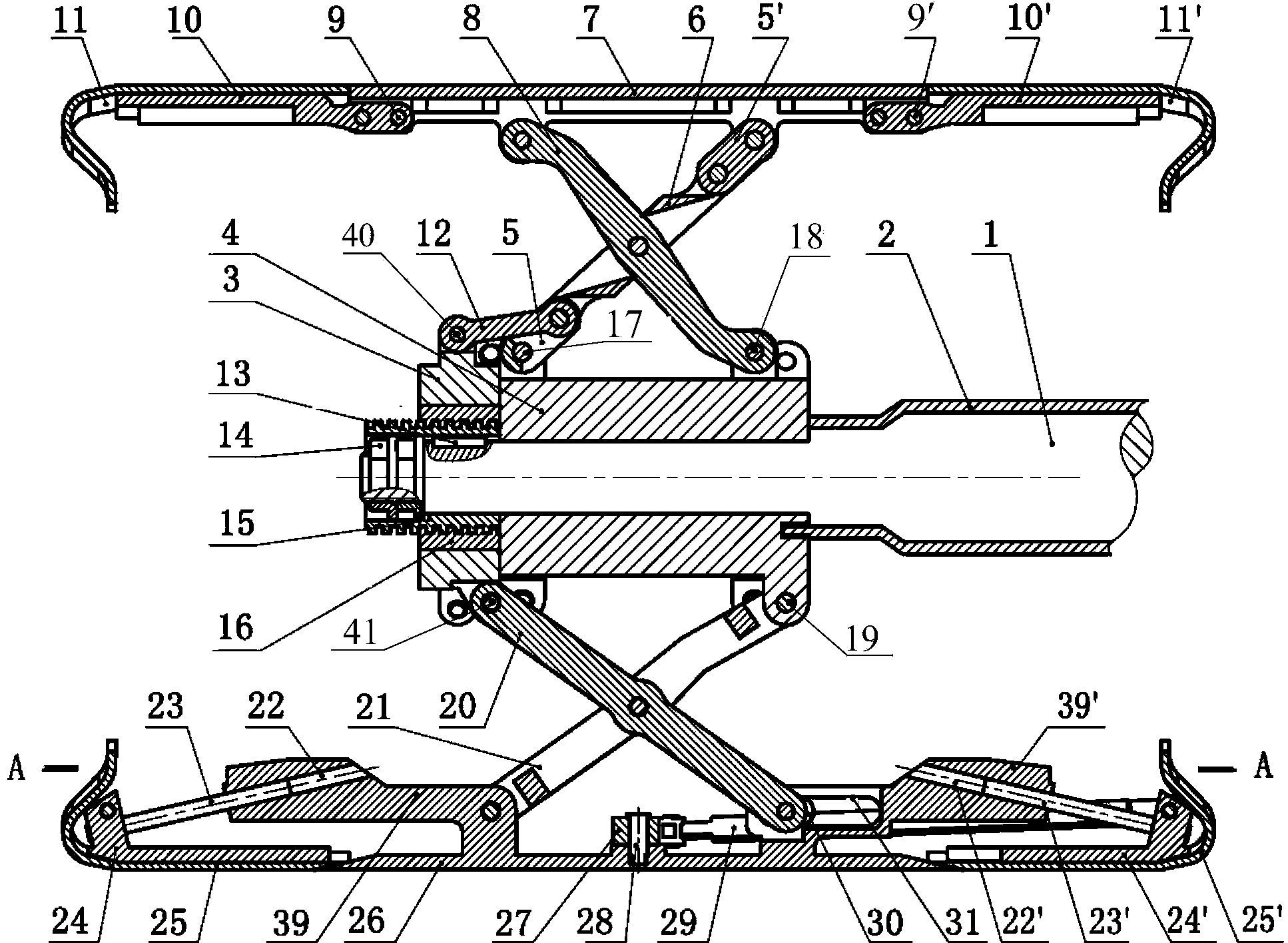

[0030] Such as Figure 1a , 1b As shown, the giant OTR tire building drum includes: a drum shoe group, a drum shoe expansion and contraction mechanism, and a narrow drum shoulder contraction mechanism.

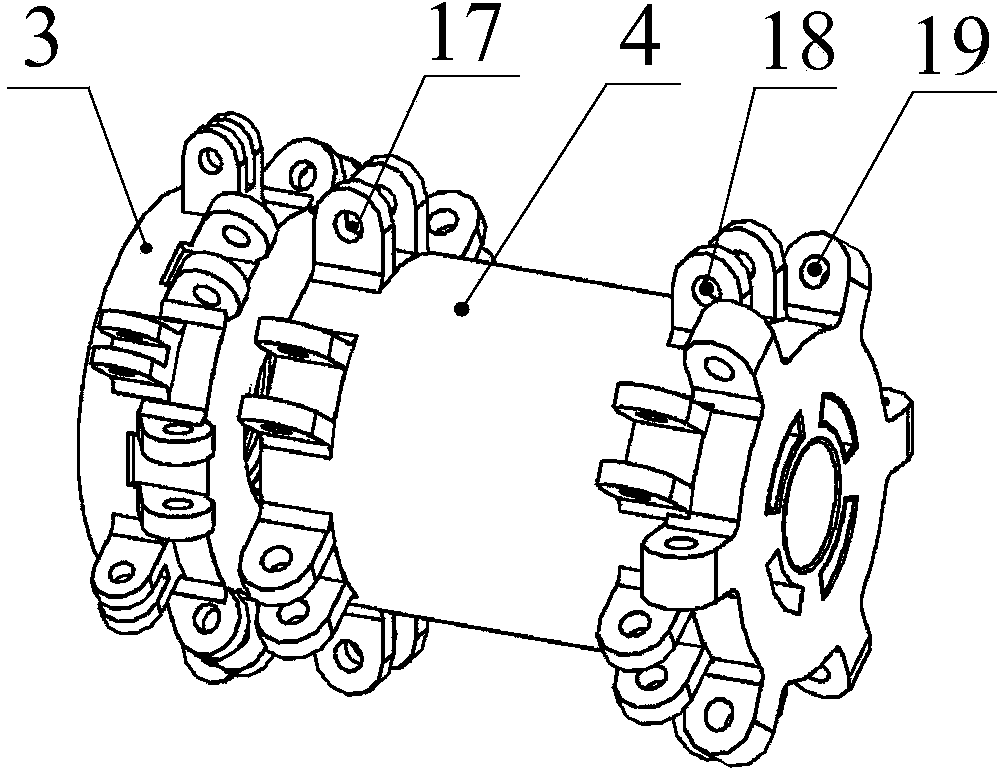

[0031] Drum tile group, including wide drum tiles 7 and narrow drum tiles 26; wide drum tiles 7 and narrow drum tiles 26 are alternately and evenly arranged in the circumferential direction of the giant engineering tire building drum, and the number of uniform distribution is six. The alternating angle between the two is 30 degrees, such as Figure 1f shown.

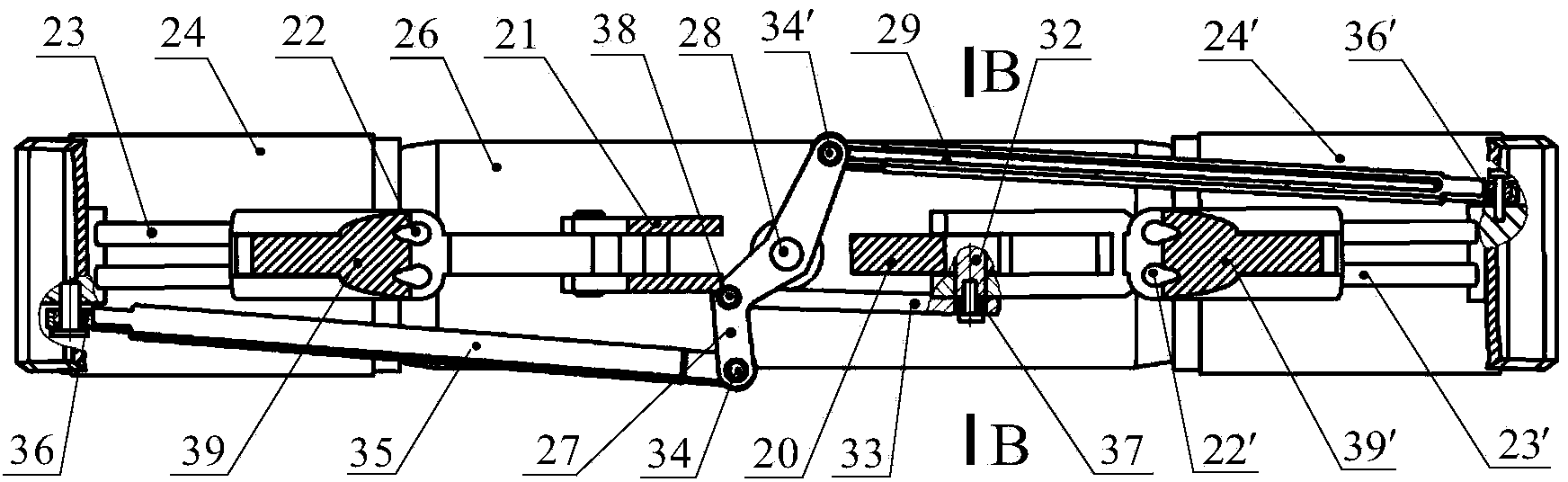

[0032] The inner side of the wide drum tile 7 has two parallel pin holes, and the wide drum tile 7 has a left wide drum shoulder 11 and a right wide drum shoulder 11' at both axial ends; the left wide drum shoulder 11 and the right wide drum shoulder The drum shoulders 11' are fixedly connected with the left wide drum shoulder connecting body 10 and the right wide drum shoulder connecting body 10' respectively; the lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com