A method for formulating the stirring position of the built-in electromagnetic stirrer in the billet crystallizer

An electromagnetic stirrer and electromagnetic stirring technology, which is applied in the field of iron and steel smelting and continuous casting technology, can solve the problems of lack of theoretical guidance on flow field behavior, incorrect stirring position, and deterioration of stirring effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] The method for formulating the stirring position of the built-in electromagnetic stirrer of the billet crystallizer, the specific steps are as follows:

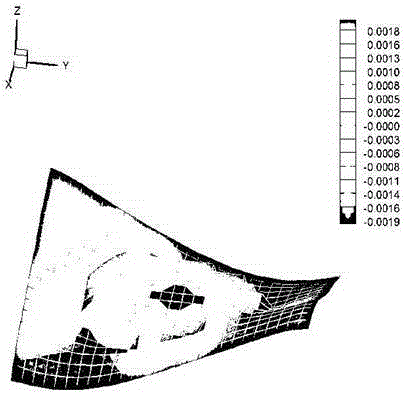

[0082] (1) Establish a flow field model

[0083] (1.1) Numerical simulation of billet mold flow field without magnetic field

[0084] The flow field in the billet crystallizer is mainly turbulent flow. According to fluid mechanics, the main parameters to be considered in establishing the turbulent flow field model are the velocity of the fluid in the X, Y, and Z directions in the coordinate system and the turbulent flow of the fluid. Kinetic energy and turbulent pulsation dissipation rate, set the speed in X, Y, Z direction with u, v, w, the turbulent pulsation kinetic energy of the fluid is expressed with K, turbulent pulsation dissipation rate with It means that the above main parameters need to be calculated on the basis of discretization equations, and the speed U(u, v, w) of the above main parameters in the X, Y, ...

Embodiment 2

[0150] The method for formulating the stirring position of the built-in electromagnetic stirrer of the billet crystallizer, the specific steps are as follows:

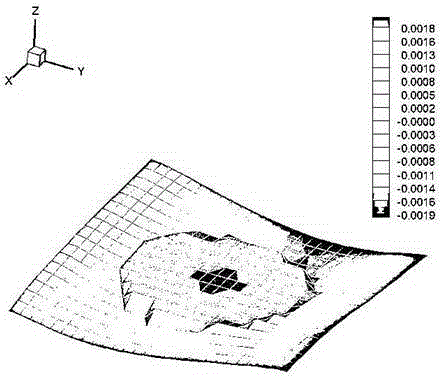

[0151] (1) Establish a flow field model

[0152] (1.1) Numerical simulation of billet mold flow field without magnetic field

[0153] The flow field in the billet crystallizer is mainly turbulent flow. According to fluid mechanics, the main parameters to be considered in establishing the turbulent flow field model are the velocity of the fluid in the X, Y, and Z directions in the coordinate system and the turbulent flow of the fluid. Kinetic energy and turbulent pulsation dissipation rate, set the speed in X, Y, Z direction with u, v, w, the turbulent pulsation kinetic energy of the fluid is expressed with K, turbulent pulsation dissipation rate with It means that the above main parameters need to be calculated on the basis of discretization equations, and the speed U(u, v, w) of the above main parameters in the X, Y...

Embodiment 3

[0219] The method for formulating the stirring position of the built-in electromagnetic stirrer of the billet crystallizer, the specific steps are as follows:

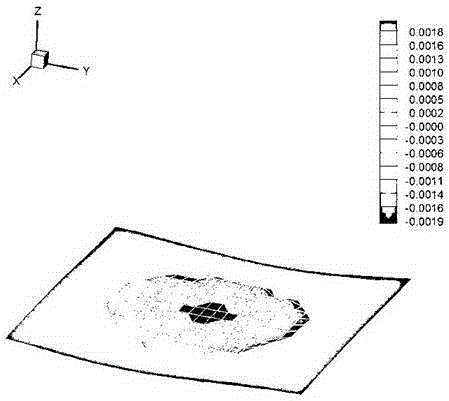

[0220] (1) Establish a flow field model

[0221] (1.1) Numerical simulation of billet mold flow field without magnetic field

[0222] The flow field in the billet crystallizer is mainly turbulent flow. According to fluid mechanics, the main parameters to be considered in establishing the turbulent flow field model are the velocity of the fluid in the X, Y, and Z directions in the coordinate system and the turbulent flow of the fluid. Kinetic energy and turbulent pulsation dissipation rate, set the speed in X, Y, Z direction with u, v, w, the turbulent pulsation kinetic energy of the fluid is expressed with K, turbulent pulsation dissipation rate with It means that the above main parameters need to be calculated on the basis of discretization equations, and the speed U(u, v, w) of the above main parameters in the X, Y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com