A c-band coupler with a rectangular notch

A rectangular notch, C-band technology, applied in waveguide-type devices, electrical components, connecting devices, etc., can solve the problems of unstable high and low temperature performance, narrow working bandwidth, poor consistency in mass production, etc., to achieve stable high and low temperature performance, improve Working frequency bandwidth, the effect of solving large interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the implementation scope of the present invention is not limited thereto.

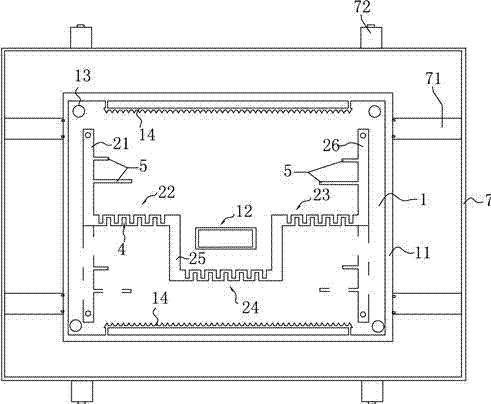

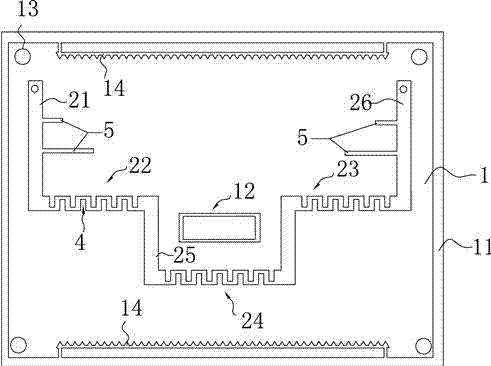

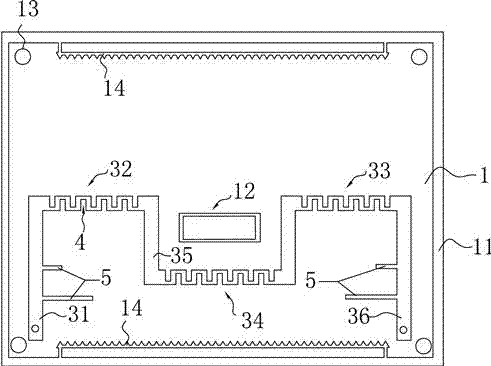

[0024] Such as Figure 1 to Figure 5 As shown, a C-band coupler with a rectangular notch described in this embodiment includes a metal casing 7, an insulating bridge 71 disposed in the metal casing 7, and a PCB board 1 disposed on the insulating bridge; The front of the PCB board 1 is provided with a first input section 21 and a second input section 26, one end of the first input section 21 extends laterally to the second input section 26 with a first coupling section 22, and the second One end of the input section 26 extends laterally to the side of the first input section 21 with a second coupling section 23; the free ends of the first coupling section 22 and the second coupling section 23 respectively extend downward with a first connecting section 25, so...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap