Front-end modules for motor vehicles

A technology for front-end modules and motor vehicles, which is applied to vehicle components, superstructures, substructures, etc., and can solve problems such as increasing repair costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The same components in different figures have the same reference numerals.

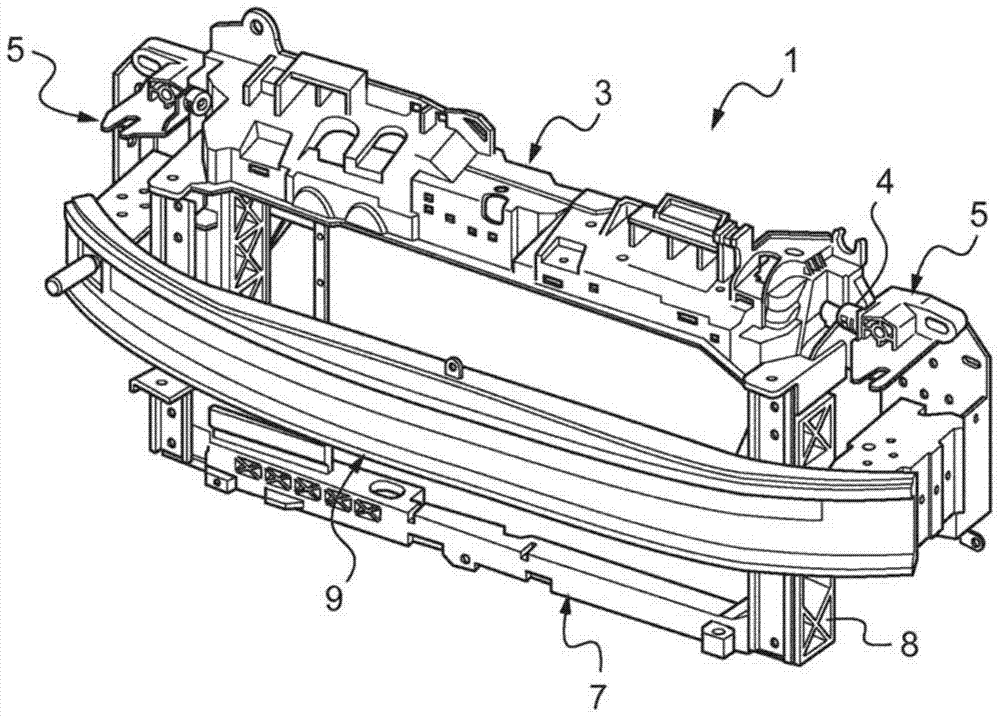

[0025] figure 1 is a schematic illustration of the front-end module. The front-end module 1 comprises support parts 3, 7, 8, to which parts such as cooling modules (not shown) can be fastened. The supporting components 3 , 7 , 8 include a bottom beam 7 , a side pole 8 and a top beam 3 . These various parts may be a single piece or separate parts fastened together. Thus, the top beam 3 can be independent and fastened to the top of the side uprights 8 . The side uprights 8 and the bottom cross member 7 may also form one and the same part, which thus has a general "U" shape.

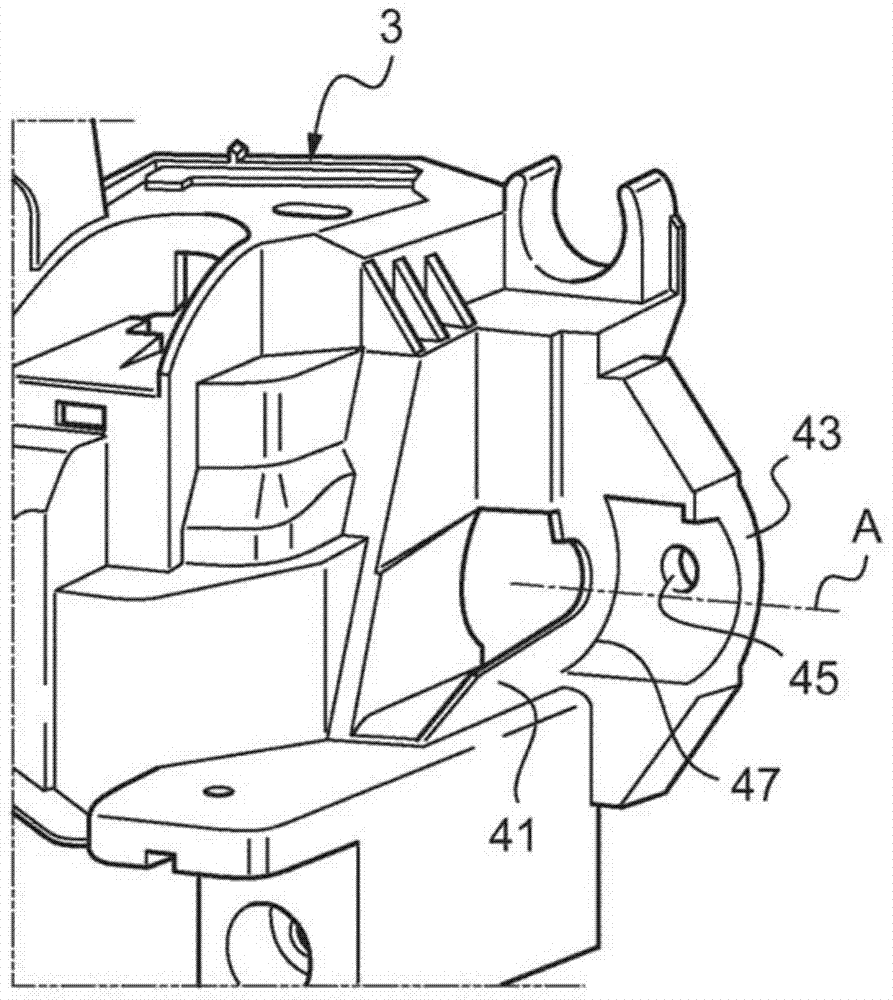

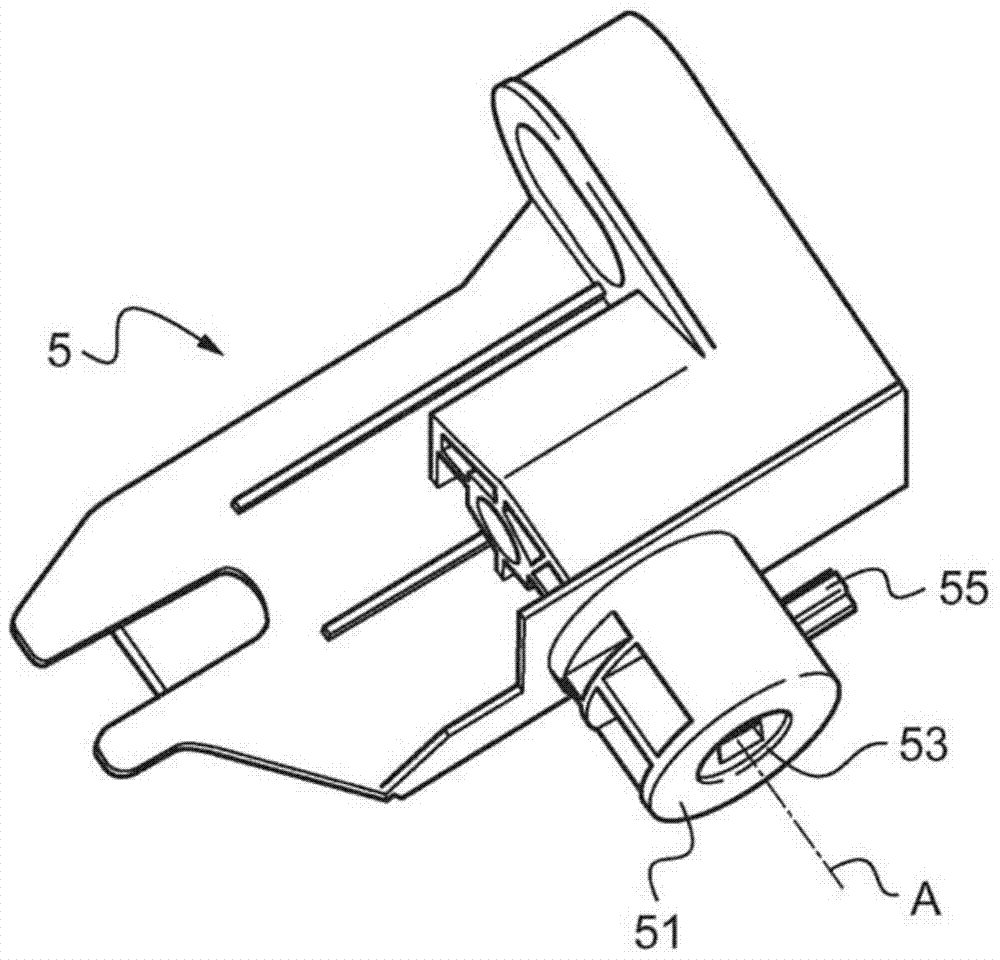

[0026] The front-end module 1 also includes a headlight support 5 on each side thereof. Said headlight support 5 is fastened on a dedicated fastening area 4 to the support parts 3 , 7 , 8 and to the vehicle chassis. The fastening area 4 can also be suitably positioned on the top beam 3 (eg figure 1 shown) or on the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com