A nanoscale three-state resistive memory and its preparation method

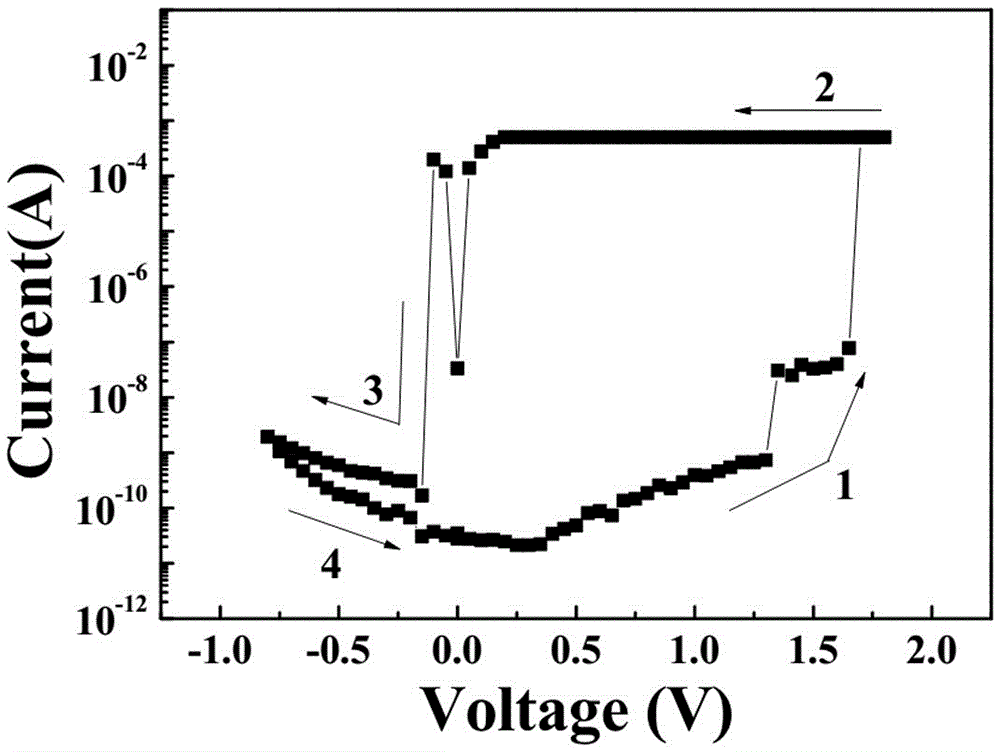

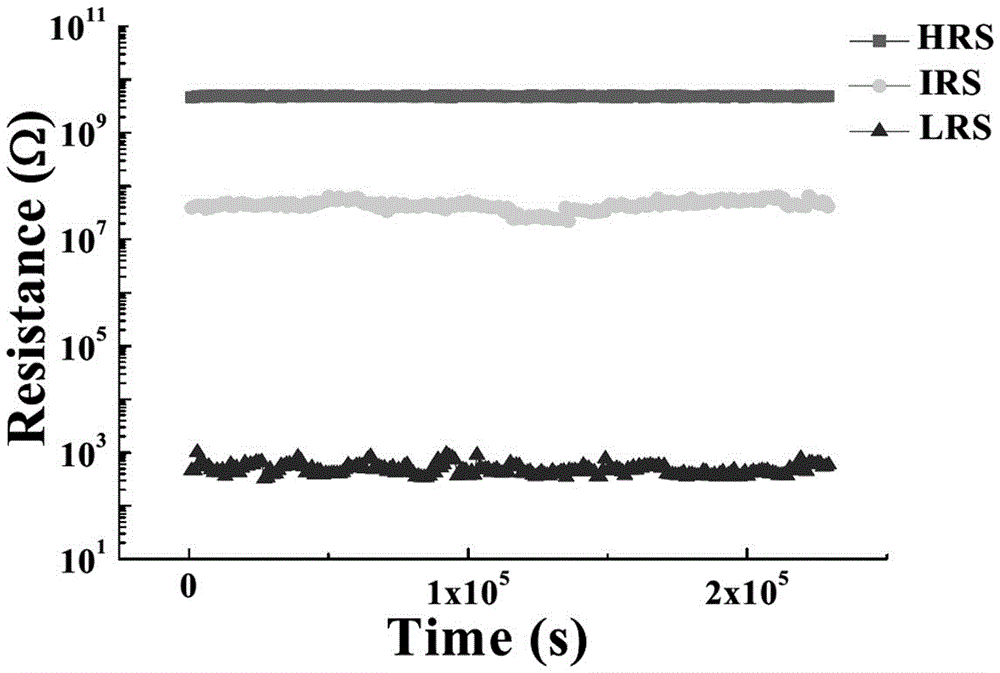

A technology of tri-state resistance and memory, applied in the direction of electrical components, etc., can solve the problems of poor switching performance and short holding time of multi-resistance resistance switching devices, and achieve the effects of good performance, significant switching effect, and good switching performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

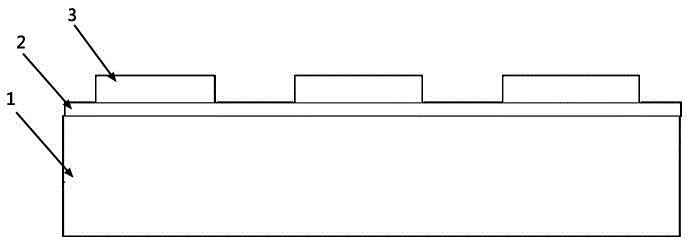

[0036] Example 1: Preparation of a three-state resistive memory with Ag / nc-Si:H / Pt structure

[0037] 1. In Pt / Ti / SiO 2 Deposition of nc-Si:H film on / Si substrate:

[0038] 1. Selection and processing of substrate materials: choose Pt / Ti / SiO 2 / Si as the substrate, first place it in acetone and ultrasonically clean it for 10 minutes, then put it in alcohol and clean it ultrasonically for 10 minutes, then take it out with a plastic clip and put it in deionized water and clean it ultrasonically for 5 minutes, then take it out and clean it with nitrogen (N 2 ) and blow dry.

[0039] 2. Put in the substrate and vacuumize: open the chamber of the PECVD equipment (radio frequency plasma enhanced chemical vapor deposition system), and put the cleaned substrate (ie Pt / Ti / SiO 2 / Si substrate) placed on the substrate table of the PECVD equipment cavity and fixed, then close the cavity, set the plate spacing to 2cm according to the conventional operation requirements, then turn on th...

Embodiment 2

[0047] Embodiment 2: the Raman spectrogram of the nc-Si:H thin film prepared in embodiment 1

[0048] Detect the Raman spectrogram of the nc-Si:H film of the memory element (i.e. the three-state resistive memory of Ag / nc-Si:H / Pt structure) prepared in Example 1 for analysis, the results are as follows Figure 5 shown. Figure 5 , the peak is located near 500cm-1, by Figure 5 It can be calculated that the crystallization rate of nc-Si:H film is 42.4%.

Embodiment 3

[0049] Example 3: High Resolution Transmission Electron Microscopy (HRTEM) image of the nc-Si:H thin film prepared in Example 1

[0050] Use high-resolution transmission electron microscopy (HRTEM) to scan the high-resolution transmission electron microscope (HRTEM) figure of the nc-Si:H film of the memory element prepared in Example 1, and the results are as follows Figure 6 shown. Depend on Figure 6 It can be seen that in the uniform amorphous network, there are small grains around the amorphous matrix, and the grains gather together in the amorphous matrix to form spherical nanoparticles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com