Retaining plate

A technology for retaining plates and traps, which is applied to suction filters, cleaning equipment, vacuum cleaners, etc., can solve the problems of expensive, complex retaining plates of plastic materials, and inability to join retaining plates, and achieve low tool cost, fast and economical production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

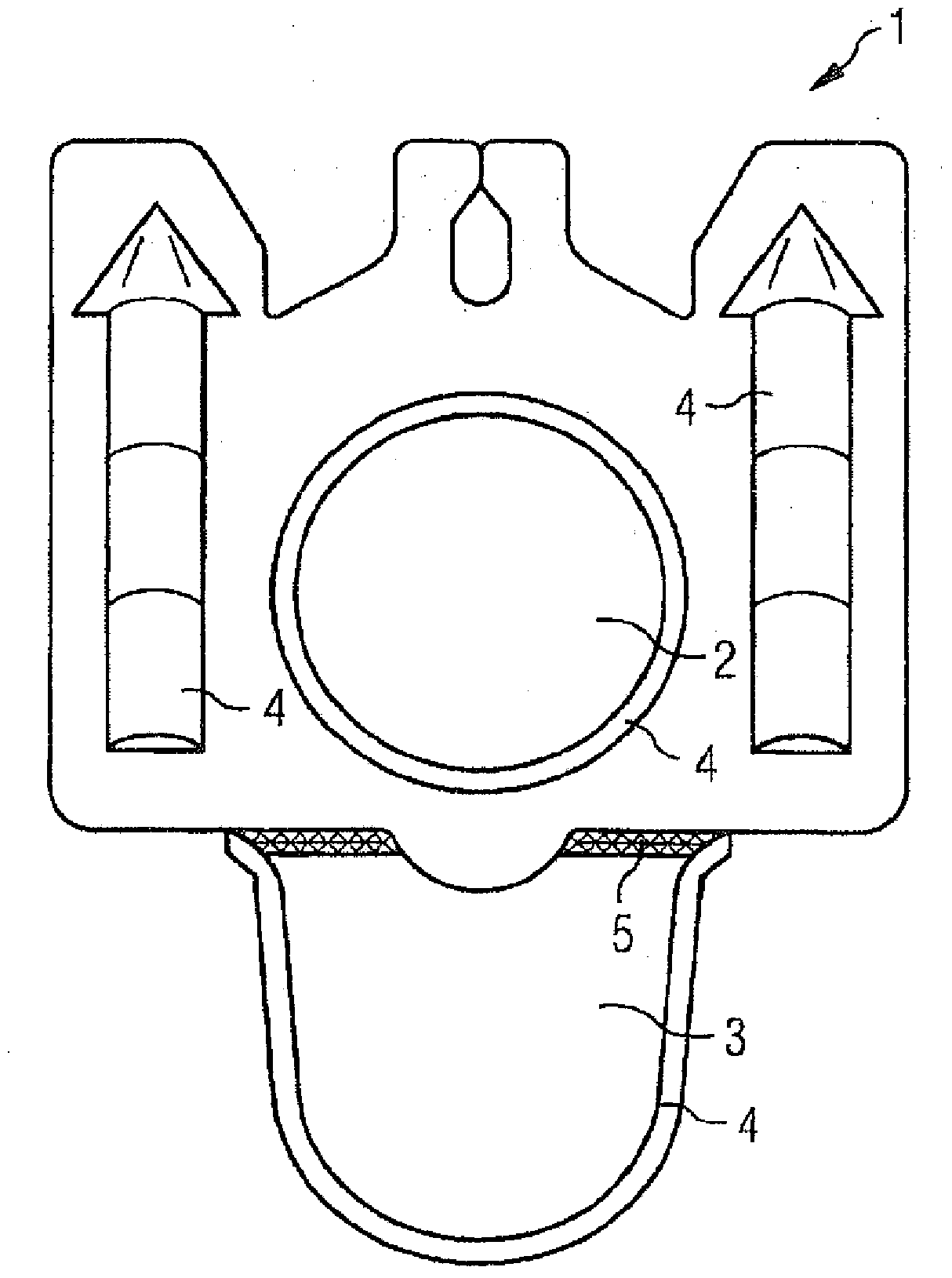

[0017] figure 1 The retaining plate 1 shown in has an inlet 2 which can be closed by a flap 3 . figure 1 The embodiment shown in is constructed as a one-piece part, ie the holding plate 1 is formed from a film by thermoforming and stamping. Such as figure 1 As described in , the retaining plate 1 also has reinforcing ribs 4 . The reinforcing rib 4 can be configured in various ways. They are preferably configured (similarly to the ribs 4 ) as arrowheads with a high-deep structure. The reinforcing ribs 4 can also be replaced by reinforcing fibers, which are present in the membrane, or which are present in combination with said reinforcing ribs. Therefore, the flap 3 is integrated with the retaining plate 1 via the film hinge 5 . Due to the fact that the flap 3 can be joined to the retaining plate 1 by means of a film hinge 5, since the flap 3 does not need to be joined to the remaining parts of the retaining plate 1 in a separate step, the flap 3 and the retaining plate 1 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com