Large-scale device of automatic silk reeling machine

A technology of silk reeling machine and dayu, which is applied in the field of dayu device, can solve the problems of many processes, labor and time, shortening the processing flow of raw silk, etc., and achieves the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

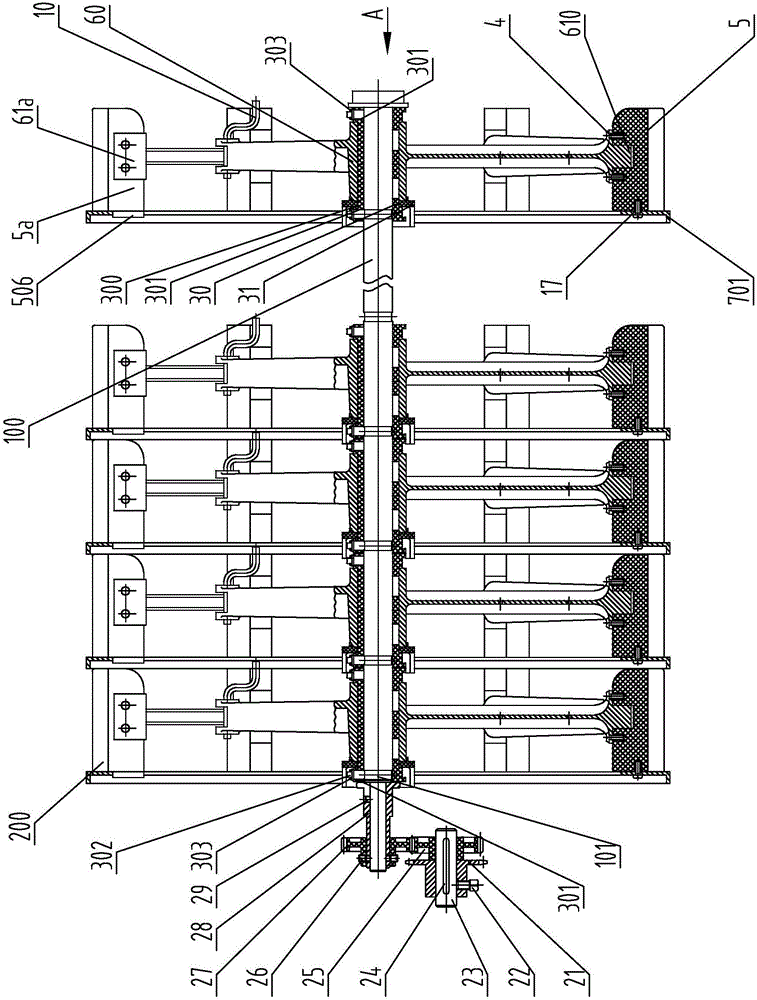

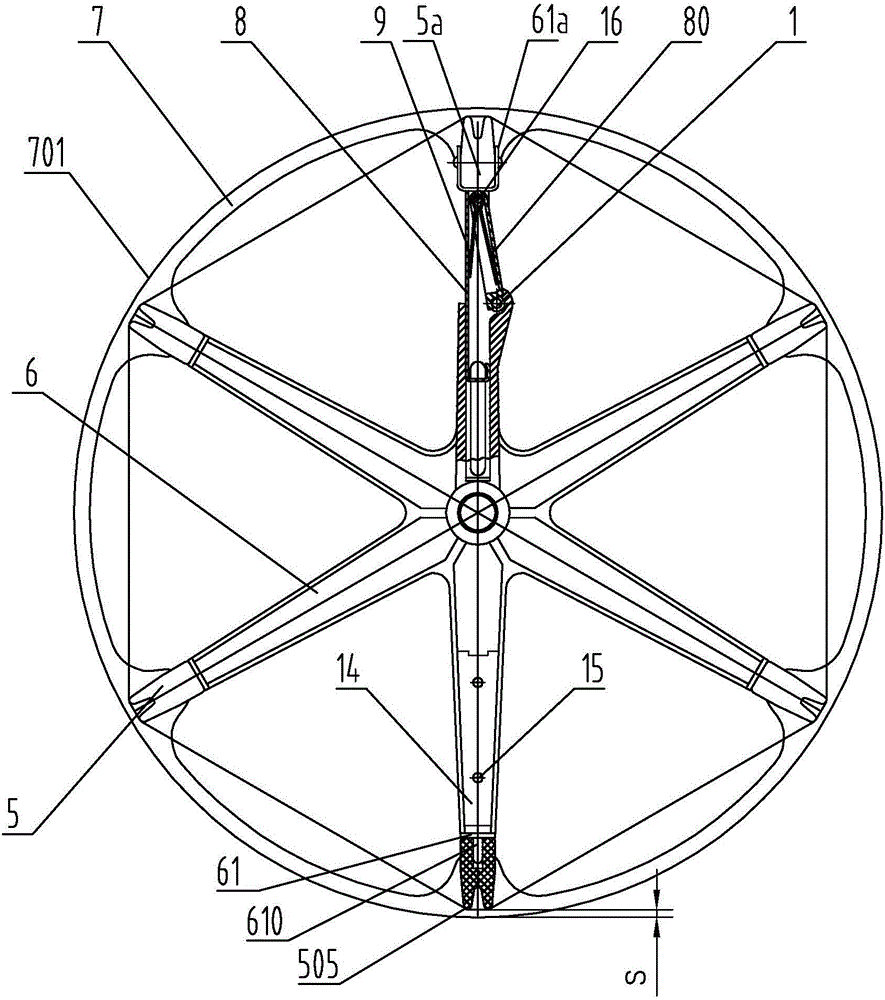

[0030] Refer to attached picture , the big yoke device of the automatic silk reeling machine provided by the present invention comprises a transmission device, a big yoke shaft 100, and a plurality of big yoke 200 for silk reeling are sheathed side by side on the big yoke shaft 100, and the big yoke 200 for silk reeling is in The axial position on the major axis is located.

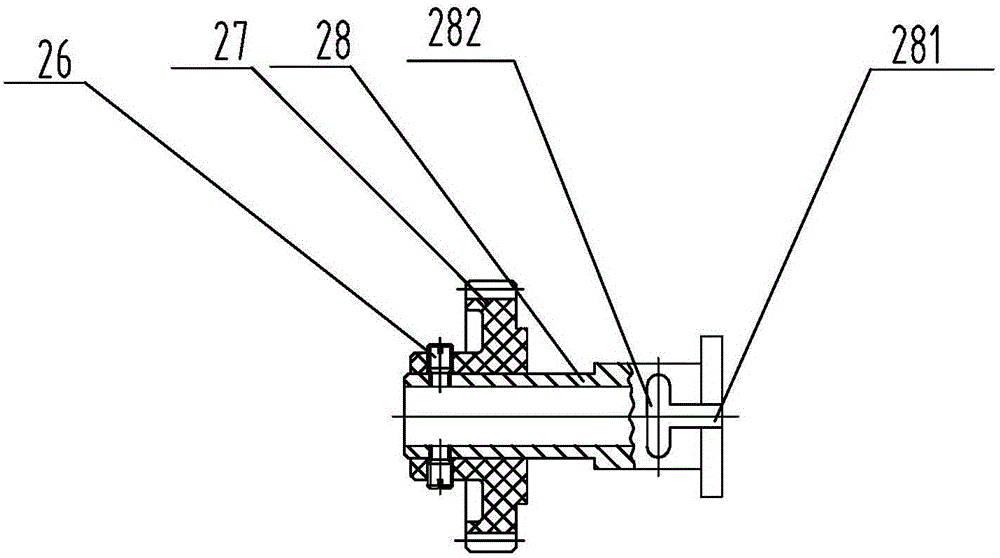

[0031] The transmission device connects the power to the large shaft 100 through the shaft sleeve 28 detachably connected with the large shaft 100, and the shaft sleeve 28 is provided with a "shaft pin introduction port 281" and a shaft pin slot 282. T"-shaped structure, the width of the shaft pin introduction port 281 and the shaft pin slot 282 is not less than the diameter of the large-Yu shaft transmission shaft pin 29, and the "T"-shaped structure is used to cooperate with the large-Yu shaft transmission pin shaft 29 to drive the shaft Cover 28 is detachably connected with big or small shaft 100.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com