Static blasting and fracturing method for low-permeability shale gas reservoir exploitation

A low-permeability oil and gas reservoir, static blasting technology, applied in the field of oil and gas exploitation, can solve the problems of poor safety, limited fracturing effect, narrow application range of blasting and fracturing technology, etc., achieve long action time, ensure continuity and effective performance, easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

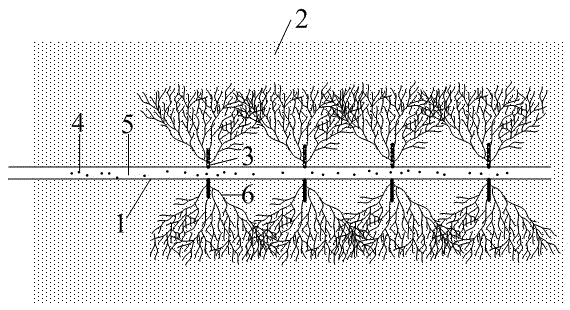

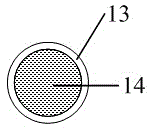

[0026] A certain shale gas reservoir has a buried depth of 2,000 meters and a thickness of 20 meters. Such as figure 1 and image 3 1 is part of the horizontal well, 2 is the shale gas reservoir, 3 is the expansion hole, 4 is the blasting agent wrapped in the biodegradable film, 5 is the hydrolase solution, 6 is the fracture; 13 is the biodegradable film , 14 is blasting agent. Drill horizontal wells to the shale gas reservoir 2 along the direction of the minimum principal stress of the formation. After cementing, perforate the production layer at 20 holes / m to obtain expansion holes 3. The diameter of the expansion holes can be 20-100 mm, and the hole depth can be 0.2 ~1.5m. Put the blasting agent 4 wrapped by the biodegradable film into the well, entrained by the hydrolase solution 5 into the expansion hole 3, the diameter of the wrapped blasting agent 5 is about 5 mm, and about 1.6 kg of blasting agent 5 is filled in each hole, and the solution 6 hydrolase The dosage is...

Embodiment 2

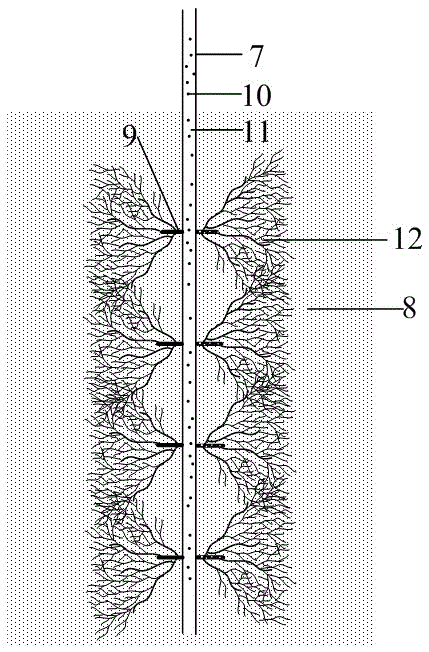

[0028] Such as figure 2 As shown, a coalbed methane reservoir is buried 1500 meters deep and 30 meters thick. Such as figure 2 and image 3 As shown, 7 is a part of the well section of the vertical well, 8 is the coalbed methane reservoir, 9 is the expansion hole, 10 is the blasting agent wrapped by the biodegradable film, 11 is the hydrolytic enzyme solution, 12 is the fracture; 13 is the biodegradable film, 14 For blasting agent. Drill vertical wells to the coalbed methane reservoir 8. After cementing, horizontally drill the production layer at 15 holes / m to obtain expansion holes. The diameter of the expansion holes can be 20-100mm, and the hole depth can be 0.2-1.5m. Put the blasting agent 10 wrapped in the biodegradable film into the well, entrained by the solution 11 of the hydrolytic enzyme into the expansion hole 9, the diameter of the blasting agent 10 wrapped in the biodegradable film is about 5 mm, and about 2 kg of the blasting agent 5 is filled in each hole, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com