A rapid method for evaluating the selectivity of iron catalysts to light olefins

A low-carbon olefin and iron catalyst technology, which is applied in the direction of chemical analysis using catalysis, can solve the problems of evaluation time not less than 10 hours and catalyst reaction evaluation time being too long, so as to improve evaluation efficiency and save time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The sample to be evaluated is a commercial ammonia synthesis catalyst HA202Q (Pingxiang Baisheng Chemical Packing Co., Ltd.).

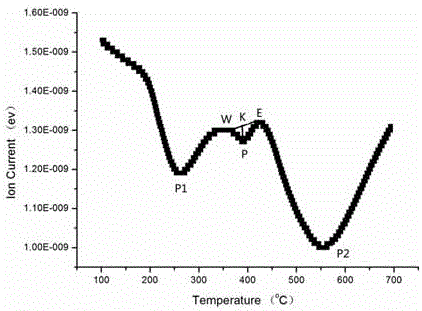

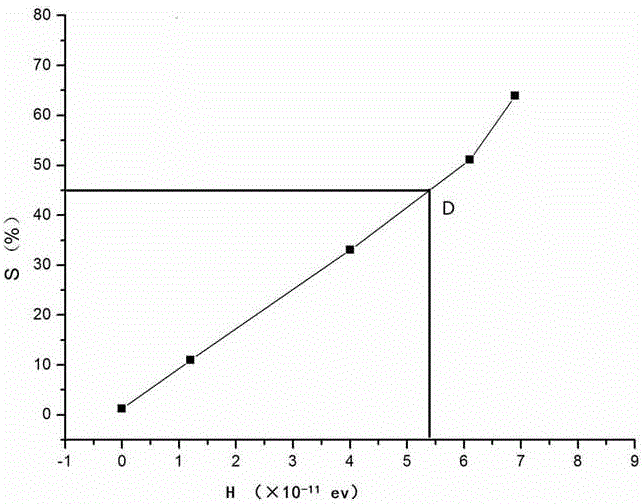

[0027] First, a carburizing performance reference curve Q is formed.

[0028] In the first step, adopt the co-precipitation method of ferric nitrate (Shanghai test, AR), manganese nitrate (Shanghai test, AR) and ammonia water (Shanghai test, GR), according to the molar ratio Mn / Fe=0, 0.001, 0.01, 0.02 and 0.05 Preparation of oxidation state samples of Fe with different contents of additive Mn;

[0029] In the second step, take 0.1 g of the sample in the oxidation state prepared in the first step, put it into the reaction unit in the test platform, and perform the reduction treatment of H2 to form a metal sample in the reduced state; the specific treatment method is that the temperature is 450 After processing for 2 hours under H2 normal pressure at ℃, switch to Ar purge for 20 minutes after cooling down to room temperature in H2 atmosphere;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com