A device for measuring the corrosion rate of downhole pipe string by flue gas and its application

A technology of corrosion rate and downhole pipe string, which is applied in the field of devices for measuring the corrosion rate of downhole pipe string by flue gas, and can solve the problems of inaccurate simulation of downhole multi-component system components and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

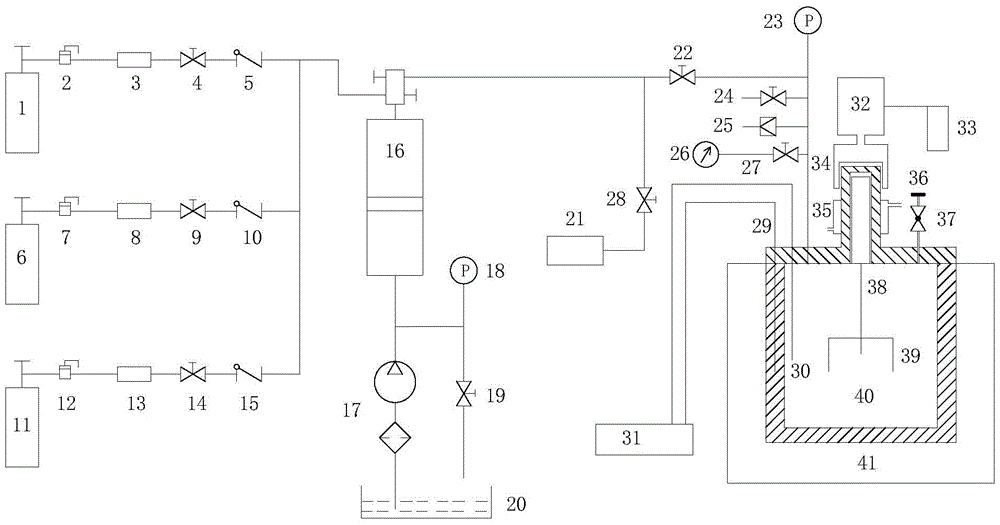

[0057] A device for measuring the corrosion rate of flue gas on downhole pipe strings, including a gas source part, a gas mixing part and a reactor 40 simulating a corrosion environment;

[0058] The gas source part includes a nitrogen gas source 1, an oxygen gas source 6, and a carbon dioxide gas source 11;

[0059] The gas mixing section includes a mixing pressurized container 16;

[0060] The reaction kettle 40 of the simulated corrosive environment comprises a kettle body, an experimental rotating part axially arranged in the kettle body, a motor 32 driving the experimental rotating part, and the experimental rotating part includes a rotor 38 and a coupon holder 39. The motor 32 includes a speed controller 33 and a magnetic transmission device 34; a rubber sealing sheet and a ball valve are arranged on the top of the kettle body; the ball valve is vertically installed on the top of the kettle body, and a rubber sealing sheet is encapsulated on the ball valve ;

[0061] T...

Embodiment 2

[0070] A device for measuring the corrosion rate of flue gas to downhole pipe strings as described in Example 1, the difference is that the pipeline between the nitrogen gas source 1 and the mixing pressurized container 16 is sequentially provided with a first decompression Valve 2, first gas mass flow meter 3 and first one-way check valve 5;

[0071] A second pressure reducing valve 7, a second gas mass flow meter 8 and a second one-way check valve 10 are arranged in sequence on the pipeline between the oxygen source 6 and the mixing pressurized container 16;

[0072] A third decompression valve 12 , a third gas mass flow meter 13 and a third one-way check valve 15 are arranged in sequence on the pipeline between the carbon dioxide gas source 11 and the mixing pressurized container 16 .

Embodiment 3

[0074] A working method of the device for measuring the corrosion rate of the downhole pipe string by flue gas as described in embodiment 1, comprising the following steps:

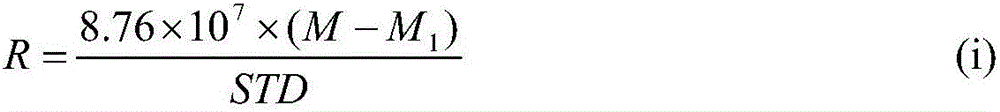

[0075] (1) Referring to the standard JB / T 7901. Metal material laboratory uniform corrosion full immersion test method, the downhole pipe string to be tested is processed into a sample to be tested that meets the above standards, and the sample to be tested is punched to measure the The mass M of the sample to be tested before the test; the sample to be tested is fixed on the rack;

[0076] (2) the coupon rack is installed on the rotor, and then the reaction kettle of the simulated corrosion environment is sealed;

[0077] (3) the valve on the pipeline between the mixing pressurized container and the reactor of the simulated corrosion environment, the valve on the pipeline between the vacuum gauge and the reactor of the simulated corrosion environment and the valve at the vacuum pump end are opened respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com