Dismountable hub motor of DC electric vehicle

A hub motor, detachable technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problems of increasing user maintenance costs, waste of resources, etc., and achieve easy, fixed and stress-resistant wheel hub replacement process reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below through specific examples.

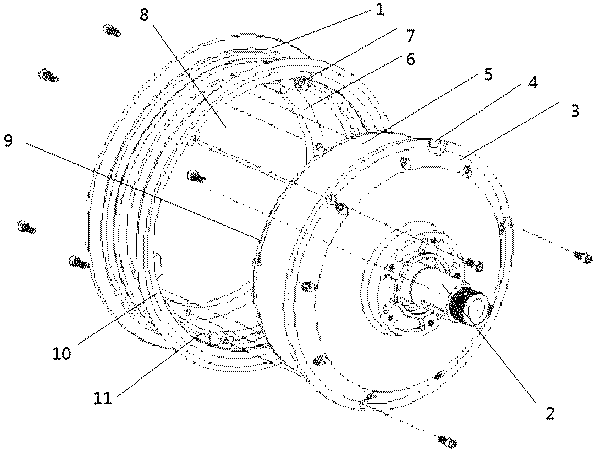

[0018] Such as figure 1 As shown, a detachable hub motor of a DC electric vehicle includes a stator and a rotor. The stator includes iron core windings, a motor shaft 2, a power line, a Hall, and a circuit board. The structure of the stator is different from that of the current hub motor. The structure of the stator is the same and will not be described here.

[0019] The rotor includes a side cover plate 3, magnetic steel and an end cover, the end cover includes a side plate portion 9 and a cylindrical portion 5, the side plate portion 9 is fixed to one end of the cylindrical portion 5, and the magnetic steel is installed on the cylindrical portion 5, the side cover 3 is rotatably mounted on the motor shaft 2, the iron core winding is located inside the cylindrical part 5 to cooperate with the magnetic steel, and the side cover 3 is fixed to the other end of the cylindrical pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com