A plastic sleeve socket device

A technology of plastic sleeves and sleeves, applied in the field of parts assembly, can solve the problems of unsuitability for use, differences in the position of plastic sleeves, time-consuming and labor-intensive, etc., and achieve the effect of reducing position differences and improving accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

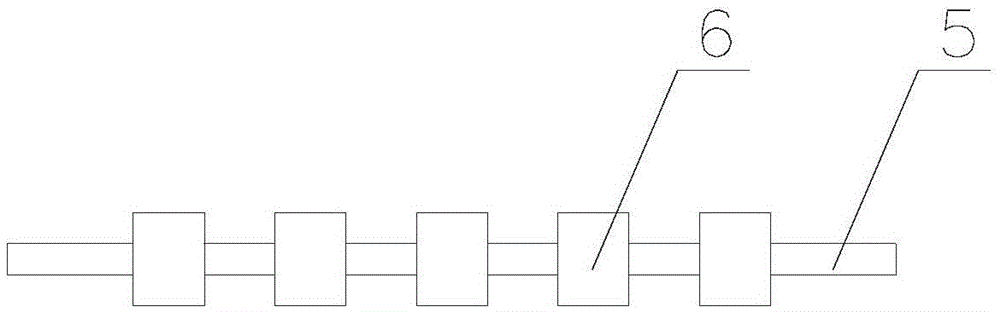

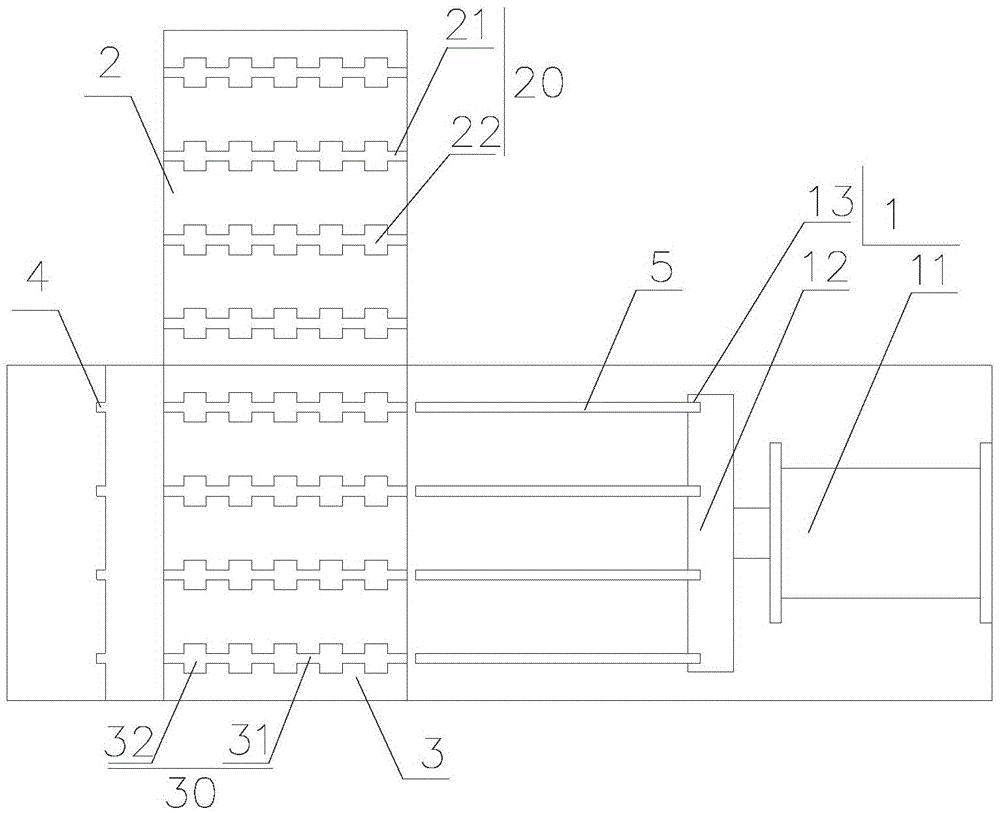

[0012] Such as figure 2 as shown, figure 2 It is a structural schematic diagram of a plastic sleeve socket device proposed by the present invention.

[0013] refer to figure 2 , a plastic sleeve socket device proposed by the present invention is used to set a plurality of plastic sleeves 6 on the stick 5 to obtain figure 1 The product shown includes a base, a power mechanism 1, and a plastic sleeve fixing mechanism. The power mechanism 1 and the plastic sleeve fixing mechanism are fixedly installed on the base, and the power mechanism 1 pushes a stick 5 through the plastic sleeve for fixing. Plastic sleeve 6 in the mechanism.

[0014] The power mechanism 1 comprises a power unit 11 and a baffle plate 12 fixed on the drive shaft of the power unit 11, the baffle plate 12 is provided with a top hole 13, and one end of the stick 5 is fitted in the top hole 13, and the power mechanism 1 pushes the stick The object 5 moves back and forth. Specifically, the power device 11 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com