Mold for injection molding and injection molding method

A technology for injection molding and moulds, which is applied in the field of injection molding molds, and can solve problems such as warping deformation, shrinkage cavity, and poor cooling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Exterior parts of products such as thin TVs and car navigation systems are sometimes used as resin molded parts and molded using molds for injection molding.

[0018] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

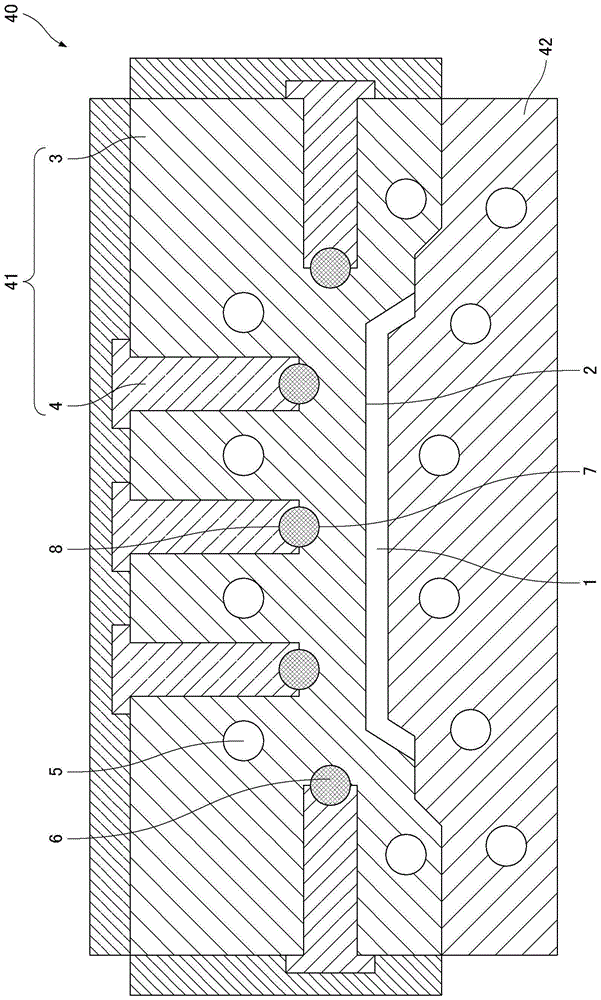

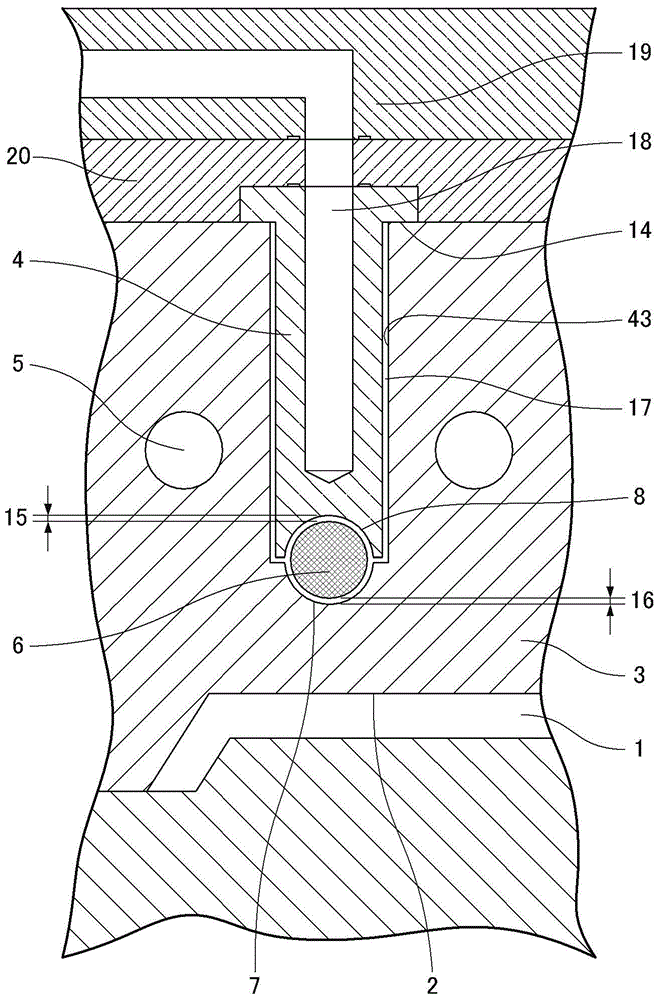

[0019] figure 1 It is a sectional view showing the structure of the mold for injection molding of the present invention, which is a view showing the structure of a mold for molding an exterior molding.

[0020] exist figure 1 Among them, the mold 40 for injection molding is composed of an upper mold 41 and a lower mold 42, and the space formed when the upper mold 41 and the lower mold 42 are combined constitutes a cavity 1, which is a molding area of a resin molded product. The cavity surface 2 of the cavity 1 becomes the outer surface of the resin molded part, and when a high-gloss surface is required, it is mirror-polished. The upper mold 41 is divided into a first slug 3 and a second slug 4 . Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com