Method for the prevention of mist formation in a device comprising rolls during the coating of flexible supports with a cross-linkable liquid silicone composition

A roll coating, silicone technology, applied to the surface coating liquid device, coating, etc., can solve the problem of not providing quantitative factors for evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0343] 1) preparation of antifogging additive E:

[0344] In the following examples, the following compounds were used.

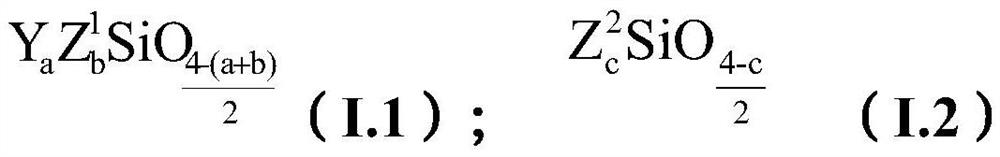

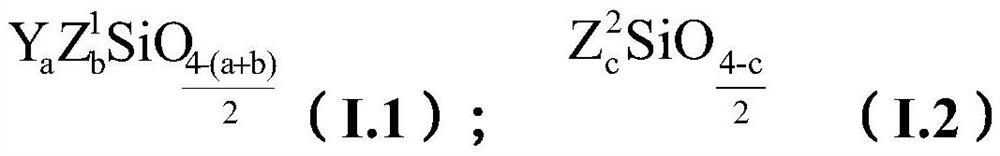

[0345] F1: organopolysiloxane of the following formula having 31 mmol of acrylate functional groups per 100 g.

[0346]

[0347] F2: Silmer ACR Supplier Siltech Corporation, which is a dimethyl polysiloxane with two acrylate functional groups at the chain ends, has 50 mmol of acrylate functional groups per 100 grams.

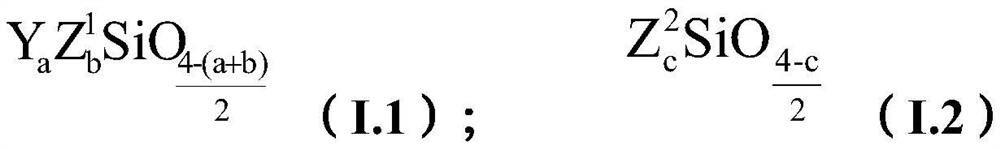

[0348] G1: organopolysiloxane having the same general formula as F1, with 199 mmol of acrylate functional groups per 100 g.

[0349] H1: hexanediol acrylate with 885 mmol of acrylate functional groups per 100 g.

[0350] N1: organopolysiloxane of the formula having 43 mmol of amine functional groups per 100 g.

[0351]

[0352] Isopropanol

[0353] Synthesis of branched polymers:

[0354] All compounds tested as anti-fogging additives were synthesized by the same method.

[0355] Compounds F, G, H and N were introduced into th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com