A conductive rod assembly tooling

A technology for assembling tooling and conductive rods, which is applied in the direction of cable laying equipment, etc., can solve the problems of increasing the cost of use, heavy tooling, increasing the labor load and operation difficulty of installing conductive rods in the busbar tube, and achieving the effect of easy portability and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

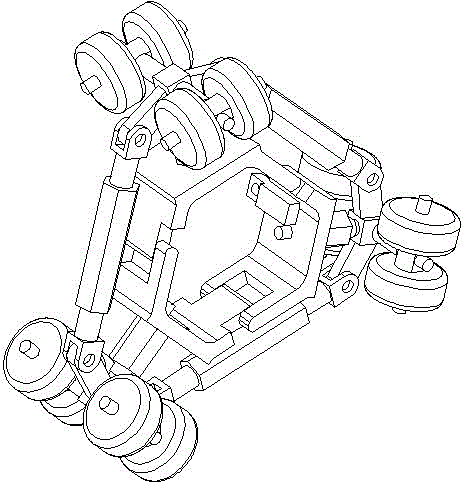

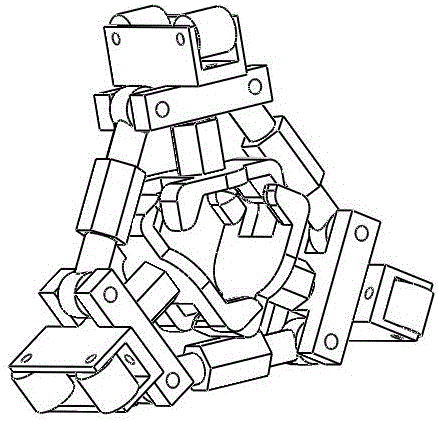

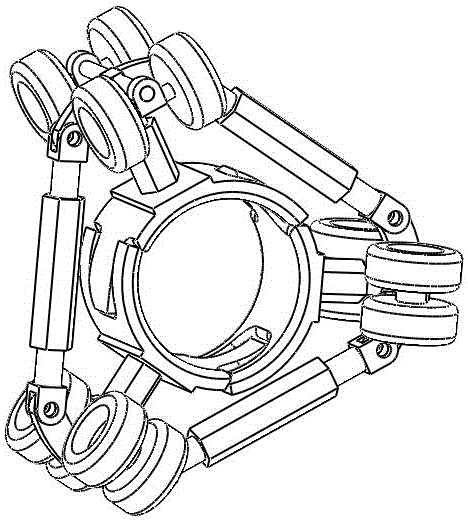

[0031] Embodiment 1 of a conductive rod assembly tooling of the present invention: as Figure 1-9 As shown, it includes three support frames 1 evenly distributed on a circumference, the center of the circle where the three support frames 1 are located coincides with the axis of the installed pipe 21, and two adjacent support frames 1 are connected to each other through an adjustable connection mechanism , and form a ring-shaped outer frame, three support frames 1 are connected with rollers 8 for contacting the inner wall of the installed pipe 21 at one end outside the ring-shaped outer frame, and three support frames 1 are connected at one end inside the ring-shaped outer frame. The supporting plate 2 is in contact with the conductive rod 22 installed in the center of the installed pipe 21 and positions the conductive rod 22 .

[0032] The support frame 1 includes a threaded column 16 for connecting with the supporting plate 2, the threaded column 16 extends in the radial dire...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap