A fast centering positioning clamping device for u-shaped thin-walled rotary parts

A thin-walled rotary and clamping device technology, applied in the direction of grinding workpiece supports, etc., can solve the problems of difficulty in guaranteeing workpiece rotation accuracy, uneven polishing surface accuracy, lack of centering and positioning mechanism, etc., and achieves easy popularization and wide application range. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

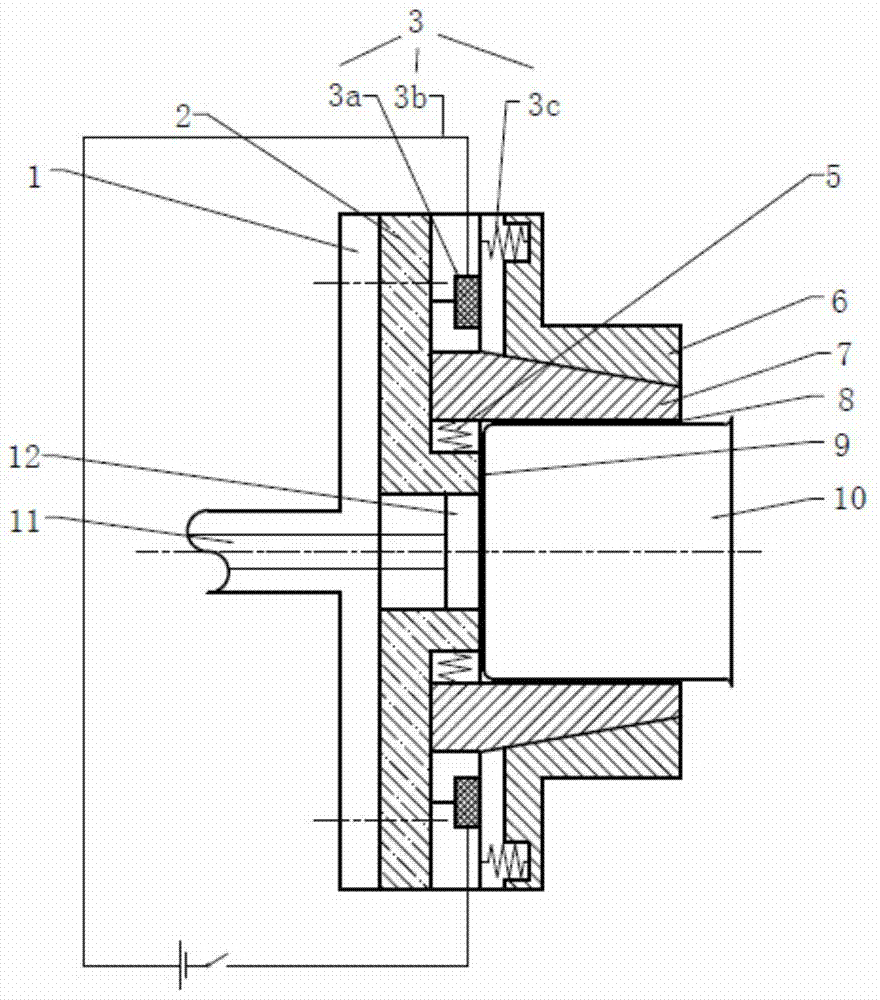

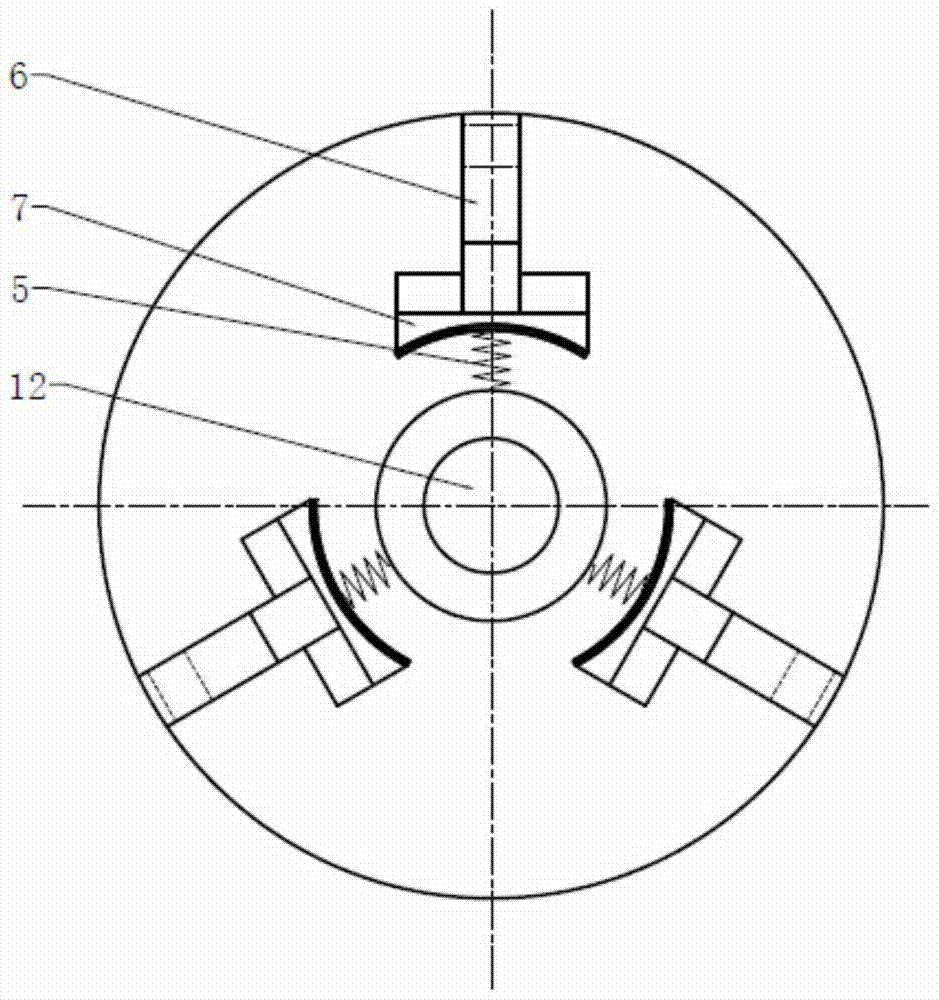

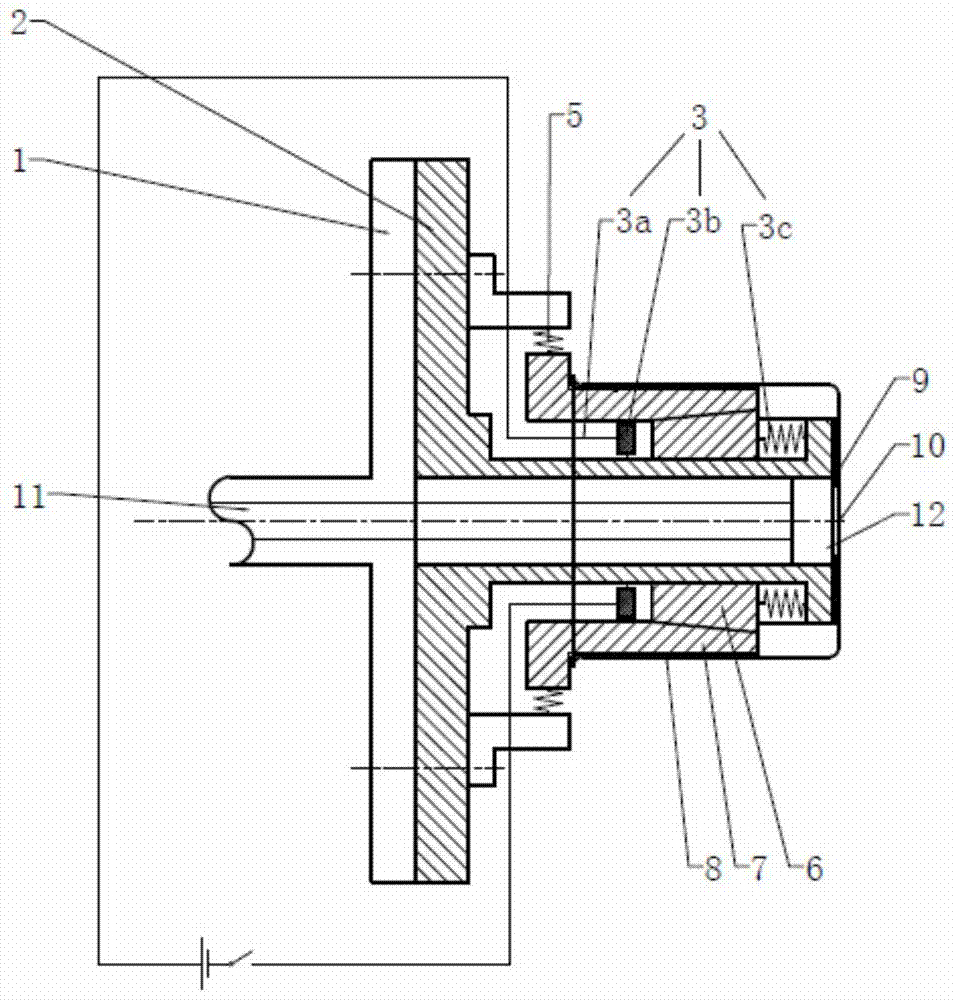

[0028] Such as Figure 1 to Figure 3 As shown, a U-shaped thin-walled rotary fast centering positioning clamping device includes a hollow rotary spindle 1, a spindle flange 2, a radially moving wedge 7, an axially moving wedge 6, and a radial reset member 5 and an axial drive mechanism 3; the hollow rotary spindle 1 has a built-in vacuum suction tube 12, one end of which is connected to a vacuum suction cup 12 to generate an attractive force to suck the bottom surface of the U-shaped thin-walled rotary member 10; the spindle flange 2 is fixed on the hollow rotary On the end of the main shaft 1, the radially moving wedge 7 is radially connected to the main shaft flange 2 through the radial reset member 5, and the axially moving wedge 6 is passed through the axial driving mechanism 3 It is axially connected with the main shaft flange, and the radially moving wedge 7 is slidingly fitted with the axially moving wedge 6; the axially moving wedge 6 is driven by the axial driving mec...

Embodiment 2

[0037] Such as Figure 4 As shown, compared with Embodiment 1, the main difference is that the axial drive mechanism is driven by the cylinder 4 or driven by an electronic push rod. Its working principle is basically the same as that of Embodiment 1, and will not be repeated here.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap