Disposable multi-piece laminated mattress 90-degree rotation mechanism and rotation method

A rotating mechanism and one-time technology, applied in packaging and other directions, can solve problems such as irregular arrangement of laminated mattresses, obstruction of laminated mattresses, failure to ensure standard opening of bag openings, etc., to solve bagging failure, bagging The effect of easy specification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

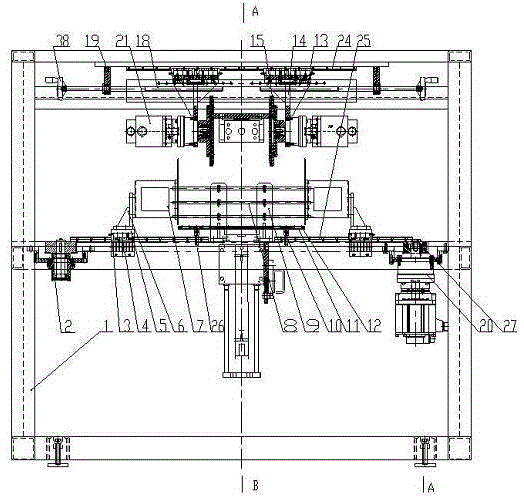

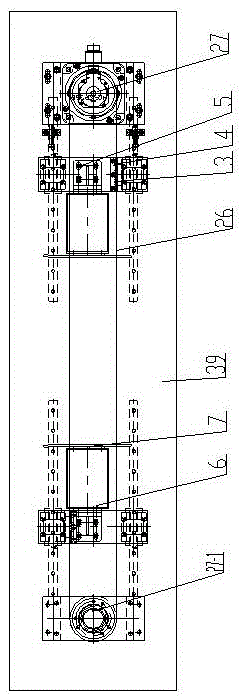

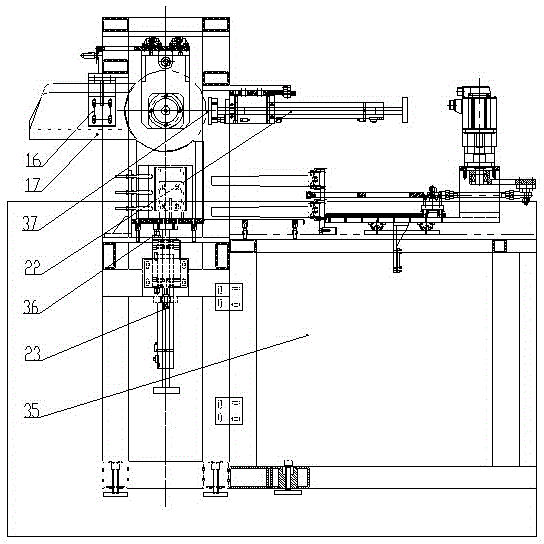

[0016] Embodiment 1: with reference to attached Figure 1-5 . A disposable multi-piece laminated mattress 90-degree rotation mechanism, including a frame 1, and two pressing plates 7 in the horizontal clamping mechanism of the laminated mattress pass through the respective timing belt splint 3 and the timing belt transmission mechanism respectively. The synchronous belt 26 is connected and driven by the synchronous belt 26 in the synchronous belt transmission mechanism to clamp or release multiple laminated mattresses, and the first push-out cylinder 23 is vertically located in the two compressed mattresses in the horizontal clamping mechanism of the laminated mattress. The first push plate 36 formed by the plate 7 under the clamping or release opening space and fixed on the piston end face of the first push-out cylinder 23 rotates and compresses the laminated mattress above the horizontal clamping mechanism of the laminated mattress In the plate mechanism, two rotating press...

Embodiment 2

[0026] Embodiment 2: On the basis of Embodiment 1, a method of rotating a one-time multi-piece laminated mattress with a 90-degree rotation mechanism, the servo motor 34 is pushed out to drive the rocker arm 33, and the rocker arm 33 drives the connecting rod A30 and the connecting rod B32 in the Under the action of the mattress product horizontal pushing plate 31, the laminated mattress is pushed out from the pinna 29 and the supporting plate 28, pushed between the pressing plate 7, the supporting plate 11, and the front bar 8, and the servo drive in the synchronous belt transmission mechanism The motor 20 drives the synchronous belt 26 to rotate through the active synchronous pulley and the passive synchronous pulley, and the synchronous belt 26 drives the two pressing plates 7 connected to it to move in opposite directions to compress the multi-piece laminated mattress to a specified thickness. After the plates 7 are compressed to the specified position, the first push plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com