Anti-glare film

A technology of anti-glare film and anti-glare layer, which is applied in the direction of identification devices, instruments, and other household appliances, can solve problems such as uneven quality, high cost, and poor quality, and achieve the effect of suppressing poor conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0173] Examples are given below to describe the present invention in more detail, but the present invention is not limited by these examples. In the examples, % and parts indicating content or usage-amount are based on weight unless otherwise specified. In addition, the evaluation methods of molds and anti-glare films in the following examples are as follows.

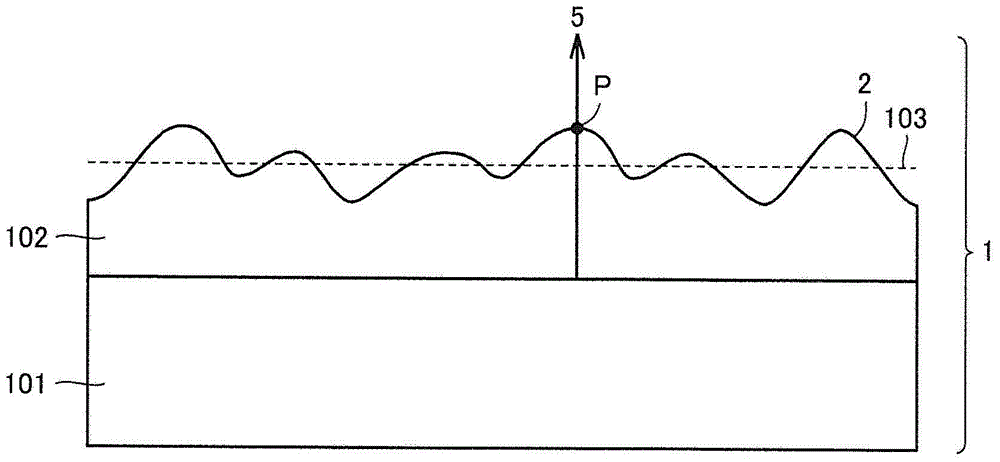

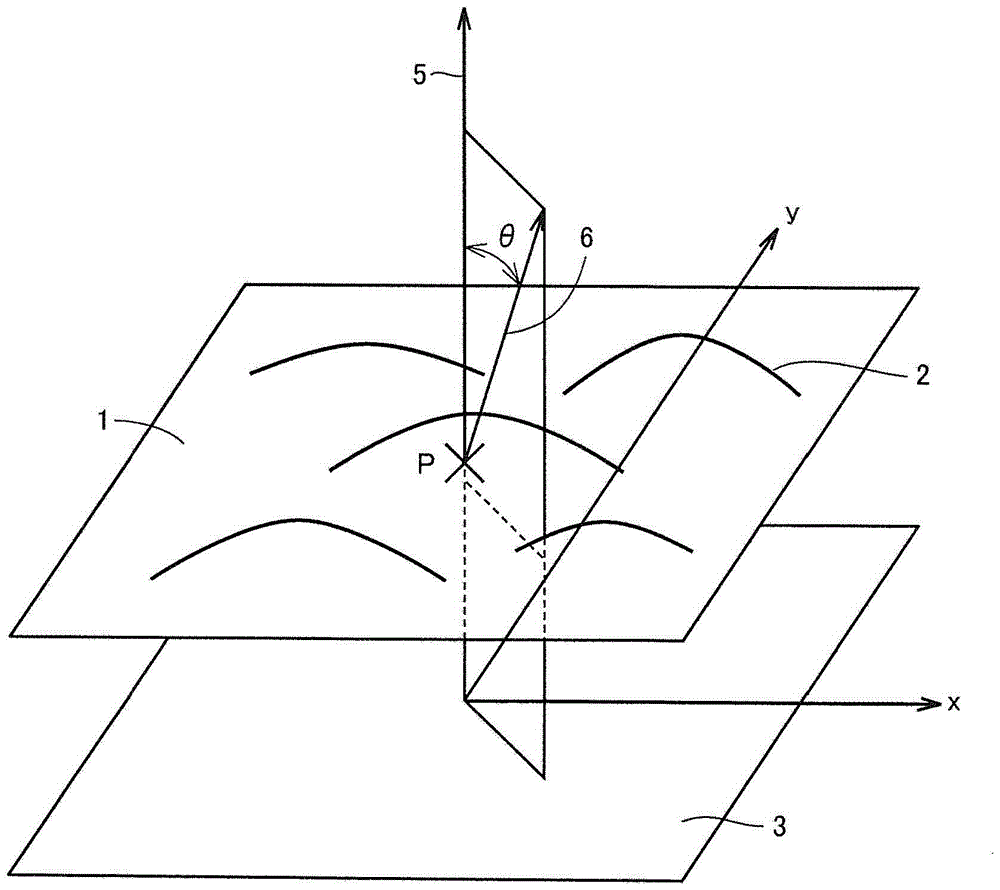

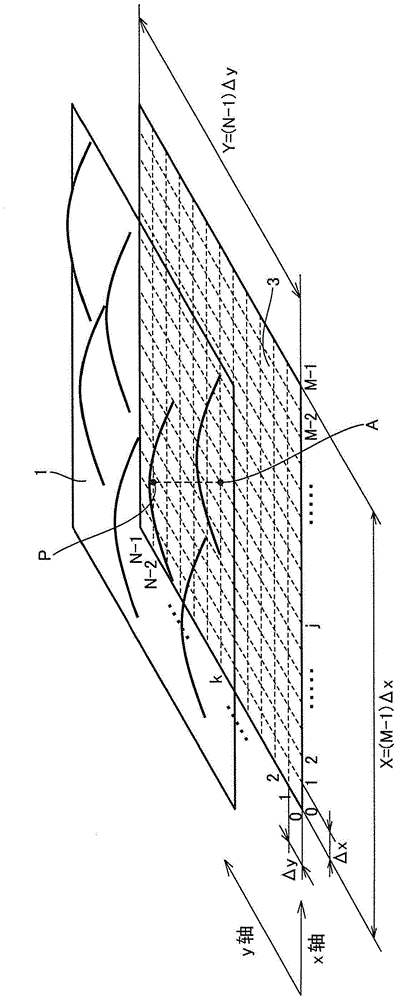

[0174] [1] Measurement of surface shape of anti-glare film

[0175] (measurement of surface altitude)

[0176] The elevation of the surface of the antiglare film was measured using a three-dimensional microscope PLμ2300 (manufactured by Sensofar). In order to prevent the warping of the sample, it was used for measurement after being bonded to a glass substrate with an optically transparent adhesive so that the concave-convex surface became the surface. In the measurement, the magnification of the objective lens was set to 10 times, and it measured. The horizontal resolutions Δx and Δy are both 1.66 μm, and the measu...

Embodiment 2

[0219] In addition to repeating the order Figure 15 The pattern shown in (made by passing it through a band-pass filter that removes components in a specific spatial frequency range from a pattern having a random brightness distribution) is exposed on the photosensitive resin film by laser light, Mold B was produced in the same manner as in Example 1, and an antiglare film B was produced in the same manner as in Example 1 except that the mold B was used.

Embodiment 3

[0221] Except having set the etching amount of the 2nd etching process to 10 micrometers, the mold C was produced similarly to Example 2, and the antiglare film C was produced similarly to Example 2 except having used the mold C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com