Planar spiral coiled tube marking forming machine

A spiral and forming machine technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of reduced work efficiency, deformation, and failure to find copper pipes in time, so as to achieve the effect of not easy to deform and improve transfer efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

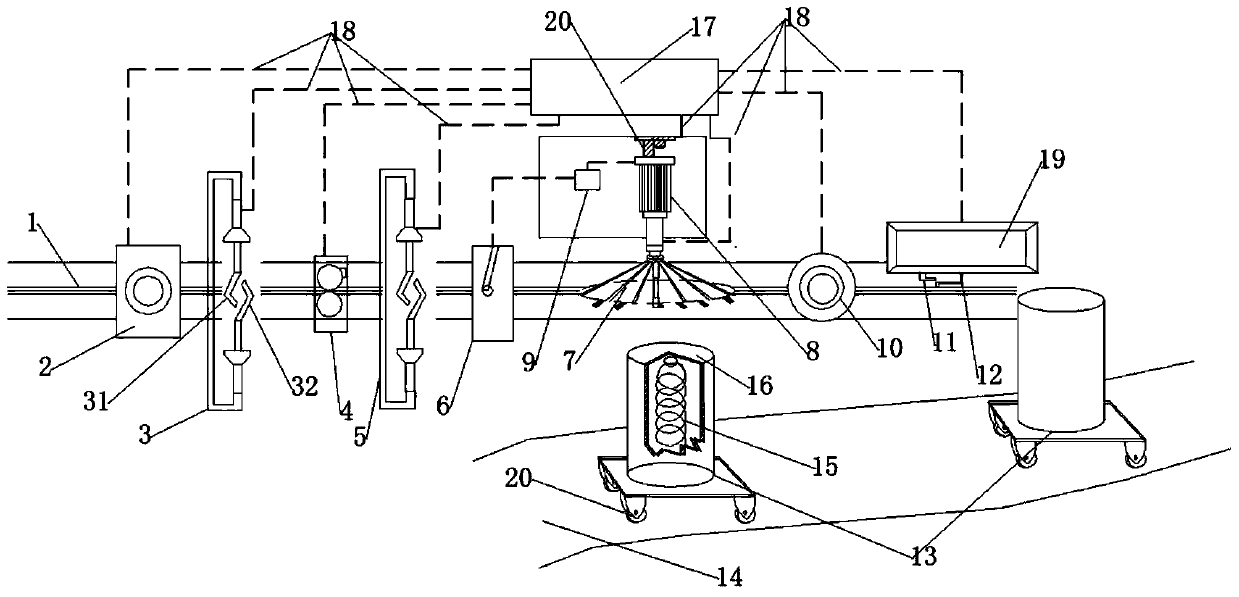

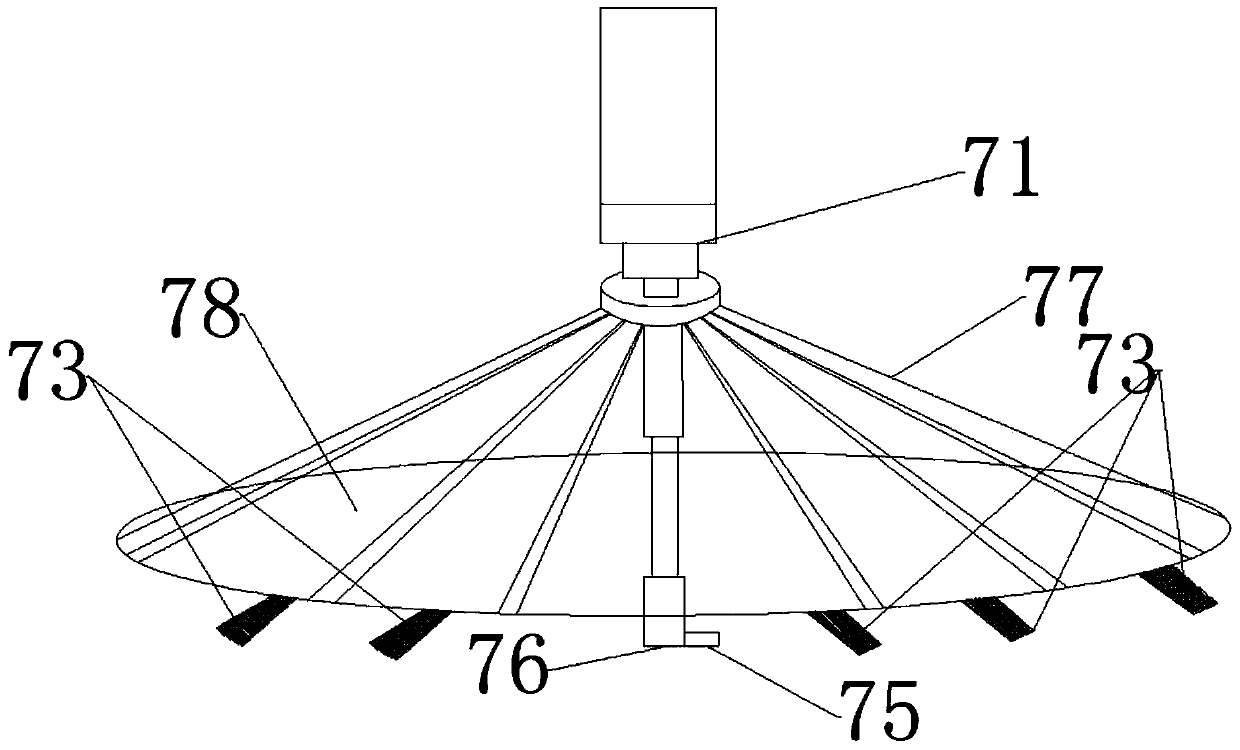

[0019] Such as Figure 1-2 As shown, a marking plane spiral coil forming machine includes: feeding slide 1, flaw detector 2, hydraulic shear 1 3, length recorder 4, hydraulic shear 2 5, detection unit 6, coiling head 7 , fast weighing device 10, marking device 19, plane spiral coil transfer tube 13; coiling machine head 7 is provided with cover body 77, and cover body 77 is connected with cover bottom 78 to form cavity, and the center of cover bottom 78 leaves for The hole through which the rotor 76 passes is provided with a stopper 75 for blocking the copper pipe passing through for the first time, and a plurality of baffles 73 are arranged around the cover body 77 to ensure the tightness of the flat spiral coil tube. The upper part of the rotor 76 A transmission shaft 71 is connected, a motor 8 is connected above the transmission shaft 71, an electric cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com