High-speed embossing, sorting, flipping, sorting and conveying device for double-layer composite material coins/chapters

A composite material and conveying device technology, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of inability to arrange and arrange the flat cakes, and cannot produce coins at high speed, so as to achieve simple and convenient conversion and installation, accurate flipping, and eliminate The effect of wrong coins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

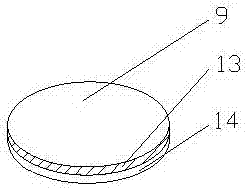

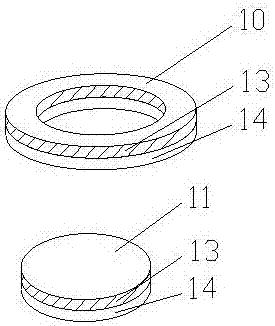

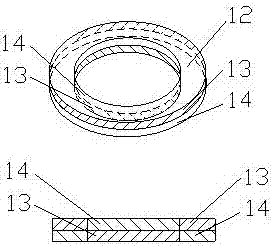

[0063] Such as Figure 4 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 The schematic diagram of the feeding device for double-layer composite material imprinting of the horizontal imprinting machine is shown, and the specific specifications are as follows:

[0064] 1. Detect coin flat cake specifications, diameter max=Φ30mm, thickness max=3mm, corresponding to the specifications of the flat cake sorter for detecting coin flat cakes, and the detection accuracy of geometric specifications is ≤0.03 mm (mm).

[0065] 2. Equipped with a cake conveying turntable with a maximum output of 1000 pieces / minute, the automatic detection speed reaches 400 pieces / minute.

[0066] 3. The coin flat cake of this device enters the cake conveying chute to set the width = Φ31mm, set the thickness = 3.2mm, to ensure the detection and detection efficiency one by one.

[0067] The mounting bracket 1 is installed on the embossing machine, and is connec...

Embodiment 2

[0079] Such as Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 14 The schematic diagram of the double-layer composite material coin imprint feeding device of the vertical imprint machine is shown, and the specific specifications are as follows:

[0080] 1. Detect coin flat cake specifications, diameter max=Φ30mm, thickness max=3mm, corresponding to the specifications of the flat cake sorter for detecting coin flat cakes, and the detection accuracy of geometric specifications is ≤0.03 mm (mm).

[0081] 2. Equipped with a cake conveying turntable with a maximum output of 1000 pieces / minute, the automatic detection speed reaches 400 pieces / minute.

[0082] 3. The coin flat cake of this device enters the cake conveying chute to set the width = Φ31mm, set the thickness = 3.2mm, to ensure the detection and detection efficiency one by one.

[0083] The mounting bracket 1 is installed on the embossing machine, and is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com