Constant pressure staged unpacking packer

A packer, constant pressure technology, used in sealing/packing, wellbore/well components, earth-moving drilling, etc., can solve problems such as early unpacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

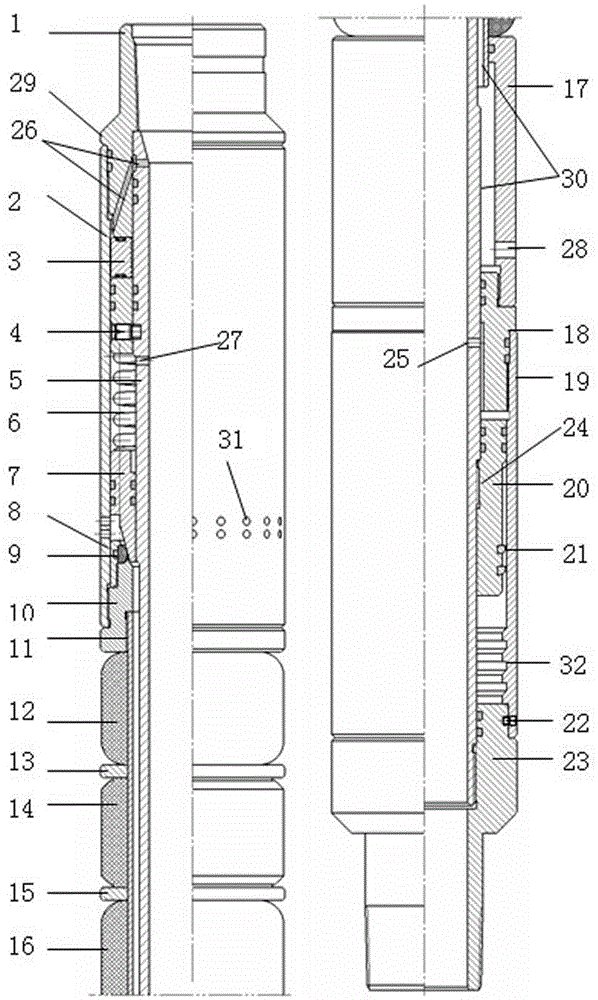

[0011] see figure 1 , a new type of graded unsealing packer of the present invention, including an upper joint 1, an upper connecting sleeve 2, a booster piston 3, an unsealing pin 4, a central tube 5, a spring 6, a well flushing piston 7, a pressure cap 8, a sealing Ring 9, base 10, outer central tube 11, upper rubber cylinder 12, upper retaining ring 13, middle rubber cylinder 14, lower retaining ring 15, lower rubber cylinder 16, lower connecting sleeve 17, setting piston 18, snap ring sleeve 19 , Circlip seat 20, circlip 21, setting pin 22 and lower joint 23 are formed. Firstly, after installing 4 booster pistons 3 into the upper joint 1 (four hollow holes are evenly distributed along the circumference on the wall of the upper joint 1, and a booster piston 3 is installed in each hollow hole), set the upper joint 1 in the center On the tube 5, install the unsealing pin 4, insert the spring 6 into the central tube 5, and make the upper end of the spring 6 push against the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com