Method for accurately monitoring closure distance between switch rail and base rail of turnout

A base rail and close sticking technology, which is applied to the locking mechanism, measuring device, electromagnetic means and other directions for turnouts, can solve the problems such as the inability to monitor the close distance between the switch tip rail and the base rail, and the inability to provide safety evaluation indicators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

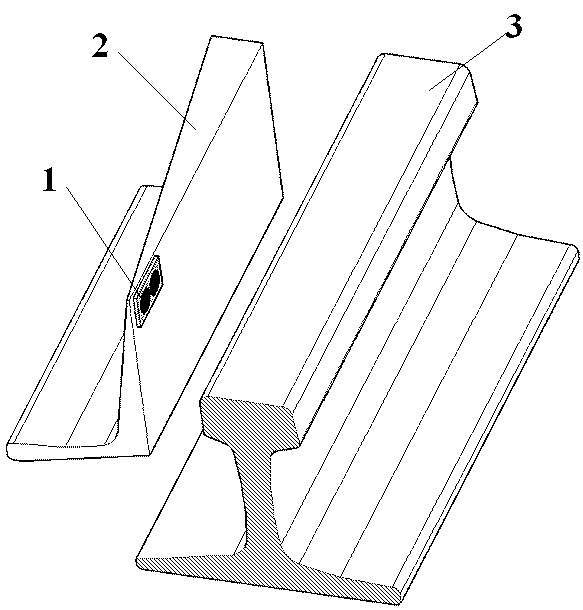

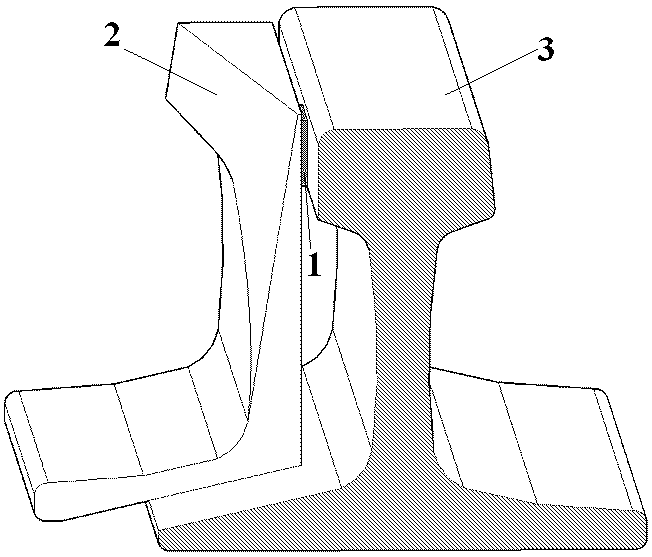

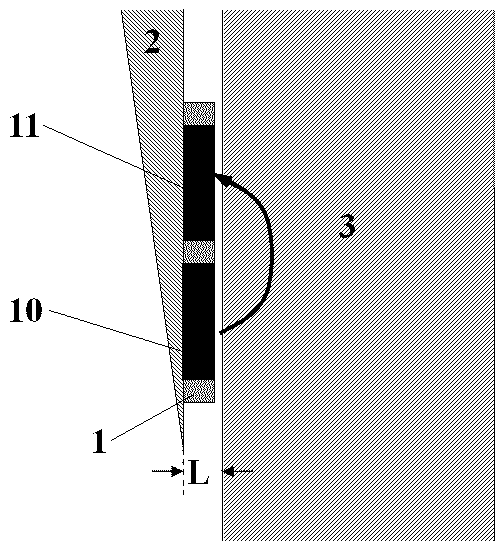

[0019] figure 1 , figure 2 , image 3 In the first embodiment shown, an accurate monitoring method for the distance between the tip rail and the base rail of a switch, the monitoring method includes two processes of initial calibration and actual monitoring,

[0020] The first calibration process is,

[0021] a. Paste and fix a sheet-shaped electromagnetic eddy current detection sensor 1 on the vertical side where the tip of the switch point rail 2 is closely attached to the base rail 3, and the electromagnetic eddy current detection sensor 1 is connected to the electromagnetic eddy current detection instrument through a sensor cable. There are two detection coils in the electromagnetic eddy current detection sensor 1 of shape, and wherein one detection coil is excitation coil 10, and another detection coil is receiving coil 11, and the thickness of electromagnetic eddy current detection sensor 1 is less than the point between switch tip rail 2 and base rail 3. The maximum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com