Switch device, leaf spring manufacturing method and leaf spring

A switch device and leaf spring technology, which is applied in the field of leaf springs, can solve the problems such as the decline of fatigue characteristics of leaf springs, and achieve the effects of inhibiting the decline of fatigue characteristics and delaying oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] One embodiment of the switch device will be described below.

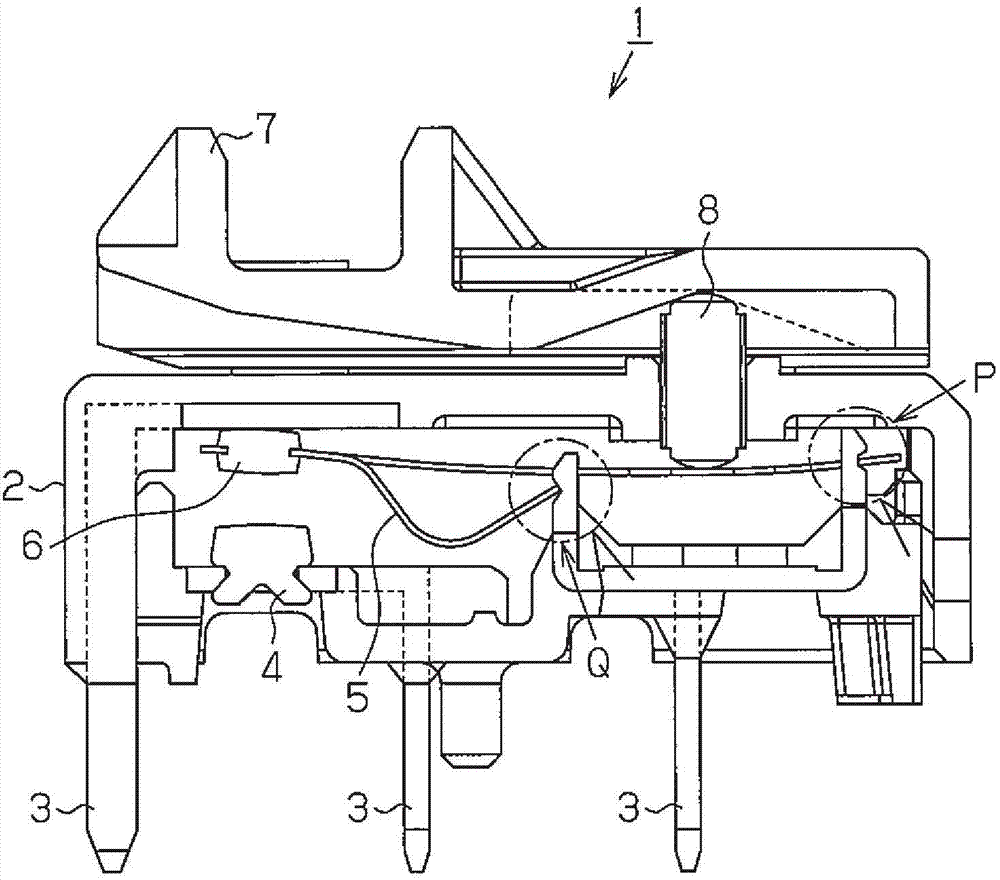

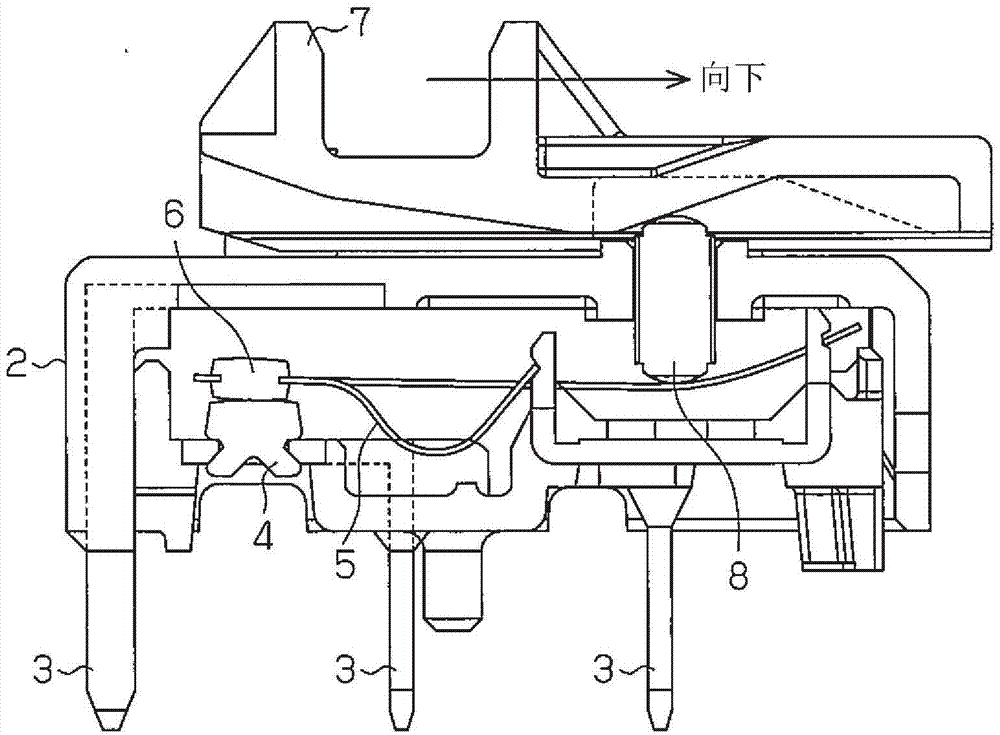

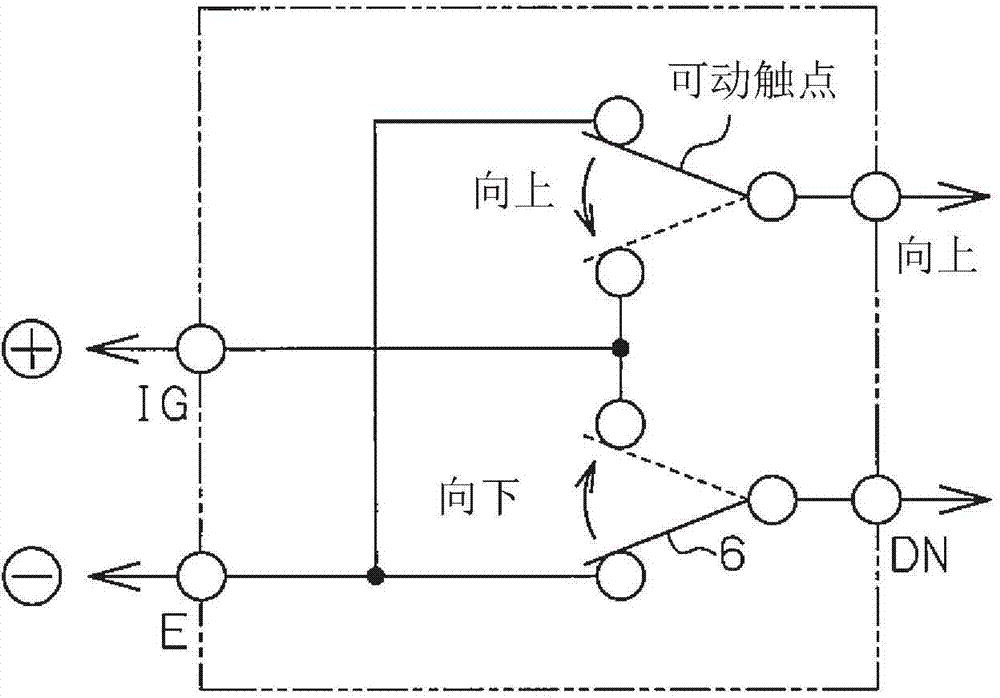

[0024] Such as figure 1 As shown, a power window switch 1 which is an example of a switch device includes an insulator 2 forming a support base. A plurality of (four in this example) terminals 3 are attached to the insulator 2 . exist figure 1 3 of the 4 terminals 3 are shown in . A fixed contact 4 is connected to a specific one of the four terminals 3 . In this example, the four terminals 3 are UP terminal, DN terminal, IG terminal, and E terminal. The UP terminal is provided in association with the upward movement of closing the door glass, and the DN terminal is provided in association with the downward movement of opening the door glass. The IG terminal is connected to the high potential side of the power supply, and the E terminal is connected to the low potential side of the power supply. In this example, the IG terminal is used for the specific terminal 3 above.

[0025] In the inner space of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com