Fully Shielded Differential Connectors

A differential connector, fully shielded technology, applied in the direction of connection, parts of connecting devices, protective grounding/shielding devices of connecting parts, etc., can solve problems such as damage to the signal integrity of transmission lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

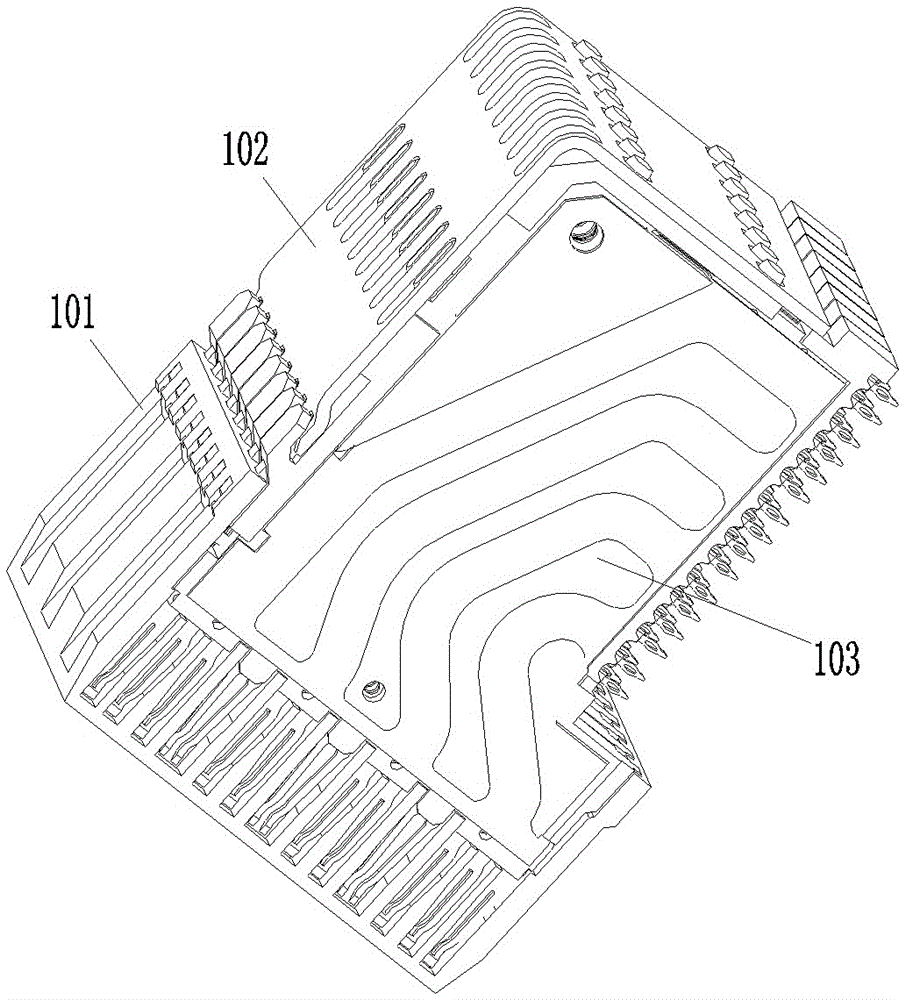

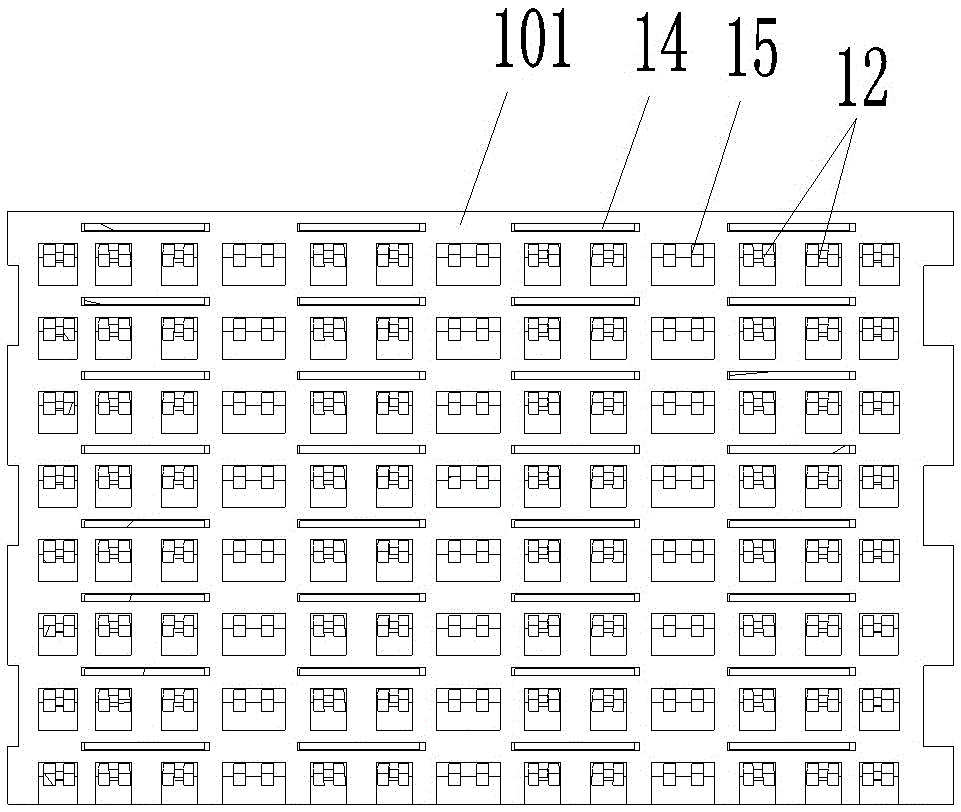

[0017] Examples of fully shielded differential connectors, such as Figure 1-6 As shown, the differential connector includes a housing 101 , a shield 102 and a differential module 103 .

[0018] The housing 101 is provided with mounting slots corresponding to the differential modules 103 one-to-one, and the shield 102 is a metal cover for cooperating with the housing 101 to fix the differential module 103 .

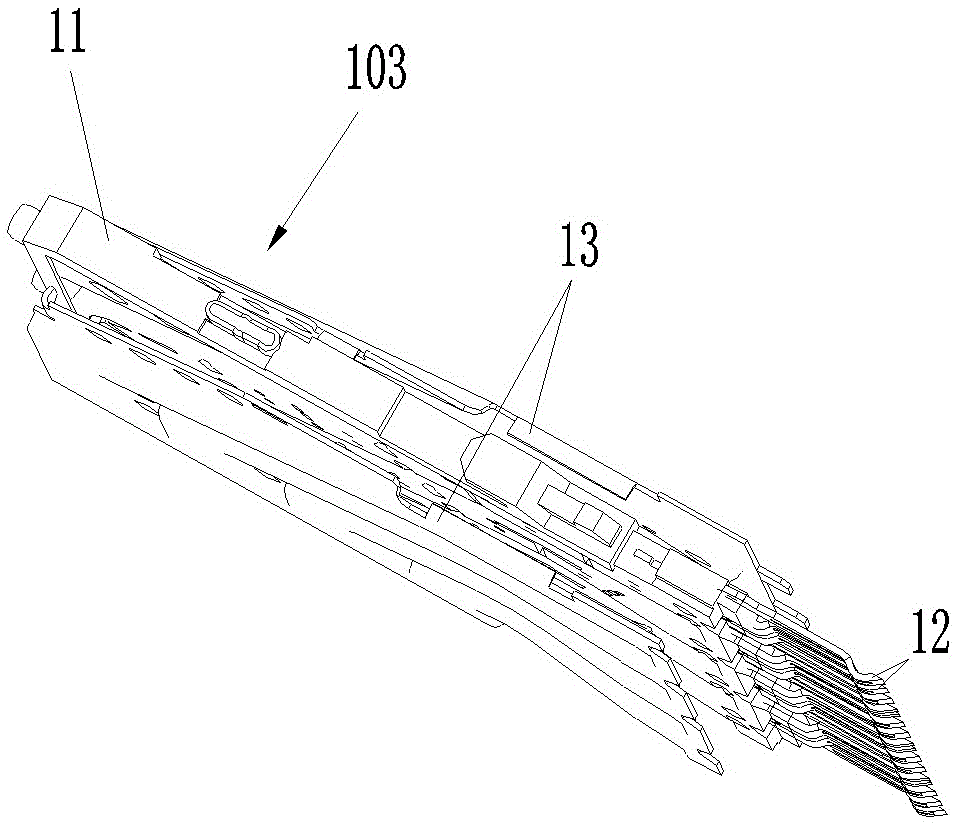

[0019] The differential module 103 includes an insulator 11 , a differential pair 12 and a ground pin 15 . The insulator 11 plays the role of combining the differential pair 12 and the grounding pin, and the two sides of the insulator are respectively provided with a wiring shield 13. In this embodiment, the wiring shield 13 is a shielding plate, which is fixedly assembled on the insulator 11.

[0020] One side of the differential pair 12 is provided with an end shield 14. In this embodiment, the end shield 14 is a shielding sheet, and the shielding sheet and the corres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com