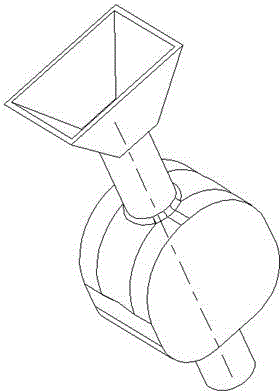

Plate-valve potato seeder

A seeding device and potato technology, applied to potato planters, planting methods, applications, etc., can solve the problem of low unit yield, achieve the effect of improving success rate, simple structure, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

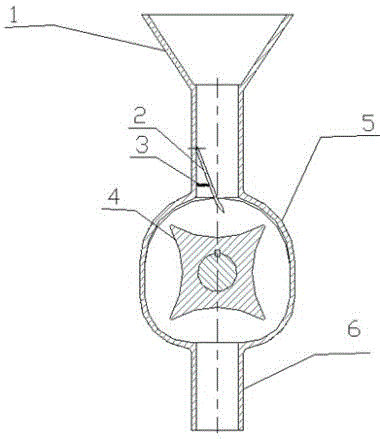

[0016] The structural composition and working principle of the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

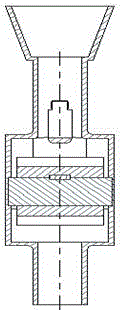

[0017] Working process: Potato seeds fall into the bottom opening of the seed box 1 due to gravity, press up the guide plate 2 and then fall to the seed metering wheel 4 close to the seed dredging tube. At this time, under the action of the compression spring 3, the guide plate 2 bounces up again to block the potato seed potatoes behind. The potato seed potatoes that fell into the seed metering wheel 4 before are sent to the bottom of the seed metering device with the rotation of the seed metering wheel 4, and are discharged through the seed metering port 6. This process is repeated continuously to achieve one-by-one sowing of seed potatoes.

[0018] As described above, similar technical solutions can be derived in combination with the content of the solutions given in the drawings an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com