Rolling-cylinder-type potato seeding device

A seeding device, potato technology, applied in potato planting machine, planting method, application and other directions, can solve problems such as low unit yield, and achieve the effects of improving success rate, simple structure, reducing void rate and replanting rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

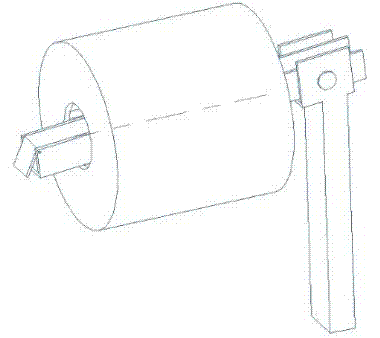

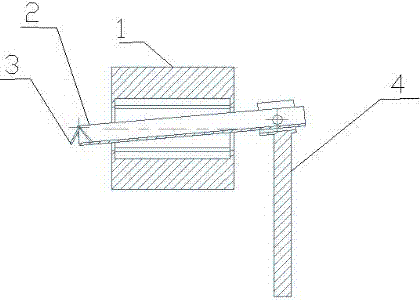

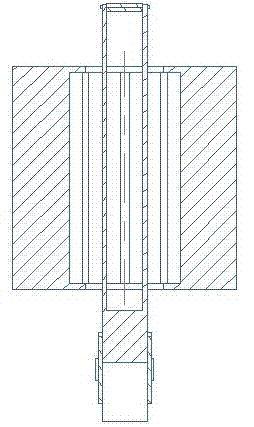

Image

Examples

Embodiment Construction

[0015] The structural composition and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0016] Working process: Seed potatoes first enter the drum 1 and rotate with the drum 1 in the drum 1. When the cylinder 1 turns to the top, the potato seeds fall into the groove of the transport track 2, and are transported to the oscillator 4 along with the transport track 2, and one end advances to the baffle plate 3 with the swing of the oscillator 4. The baffle plate 3 is always in the closed state due to the action of gravity. Whenever the seed potato is pushed forward along the conveying track 2 by the action of the vibrator 4, the baffle plate 3 will be opened once to broadcast a seed potato.

[0017] As mentioned above, a similar technical solution can be derived in combination with the solutions presented in the drawings and the embodiments. However, any simple modificatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com