Driving separation type potato seeding device

A seeding device and a separate technology are applied in the field of active separate potato seeding devices, which can solve the problems of low unit yield and the like, and achieve the effects of improving the success rate, simple structure, and reducing the void rate and the replanting rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

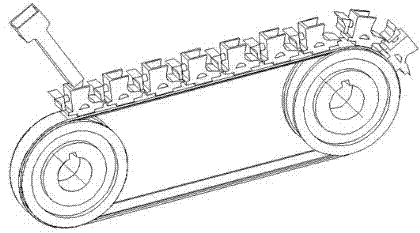

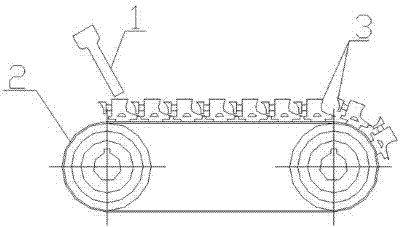

[0016] The structural composition and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

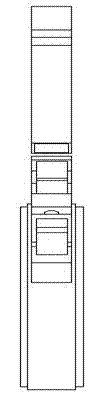

[0017] Working process: Seed potatoes first enter the hopper 1 and line up. With the continuous rotation of the pulley 2, the spring clamping device 3 constantly experiences two motion processes of linear motion and circular motion. When the spring clamping device 3 is in a circular motion, there will be a gap between the front and rear two spring clamping devices 3, and when it is about to end the circular motion and turn into a linear motion, the gap will gradually decrease; the hopper 1 The outlet is set at the position where the circular motion of the clamping device 3 is about to turn into a linear motion, so the potato seed at the bottom outlet of the hopper 1 will be clamped by the front and rear spring clamping devices 3 and brought to a straight line At the end of the motio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com