A Setting Method of Deformation Joint Obliquely Intersecting with Underground Box Culvert

A technology of deformation joints and box culverts, applied in underwater structures, buildings, artificial islands, etc., can solve problems such as unfavorable, discontinuous disconnection, and poor water-stopping effect at the corners of box culverts, achieving good waterproofing effect, saving energy The effect of the process of de-severing and re-connecting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

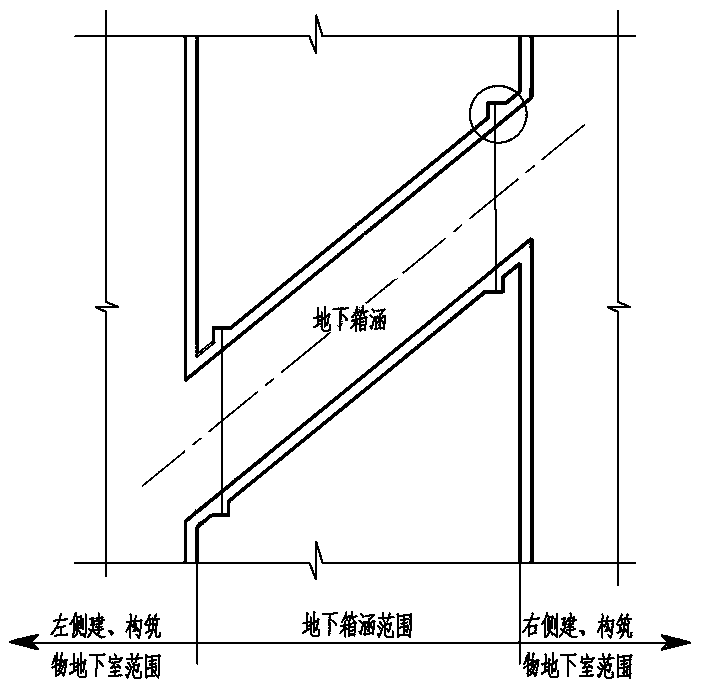

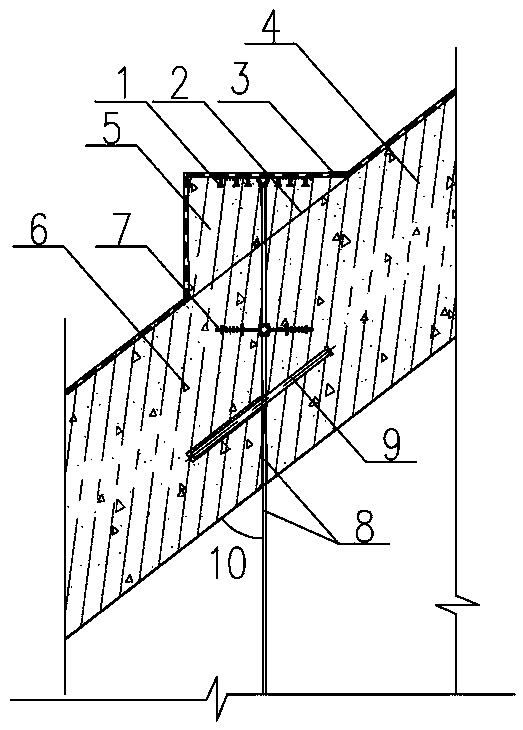

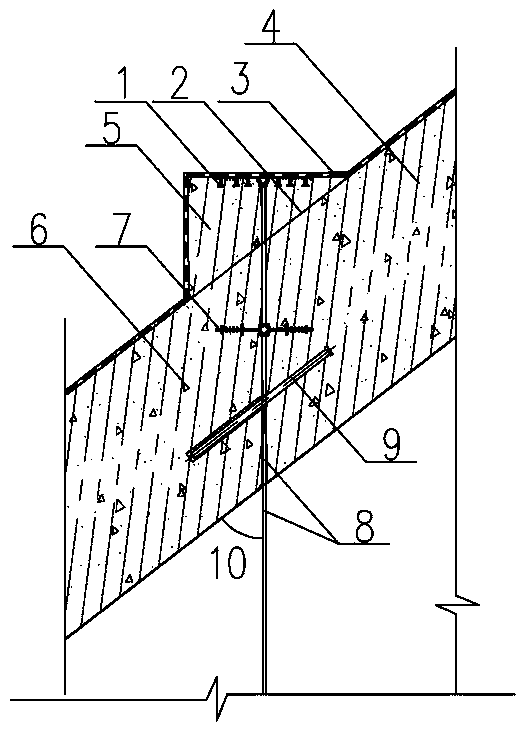

[0013] Embodiment: This embodiment specifically relates to a method for setting deformation joints obliquely intersecting with underground box culverts. By adding a convex reinforced concrete adjustment block on the side wall at the position of the deformation joints, the The external waterstop and mid-buried waterstop at the deformation joints can continuously and smoothly form a ring around the underground box culvert. The underground box culvert referred to here specifically refers to the reinforced concrete underground box culvert cast on site by the open-cut method , such as tunnels, underground passages and other underground caverns.

[0014] like figure 1 As shown, the basements of the buildings (structures) on both sides of the road need to be connected by underground passages. Therefore, the connecting channel between the two underground box culverts can only be arranged obliquely. Since the two different structures are connected, it is necessary to set up deformatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com