Fixing device applied to tension and pressure vibration fatigue test of components

A technology of fixing devices and tension-compression vibration, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of less research on fatigue resistance of beam-type member structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the drawings and specific embodiments.

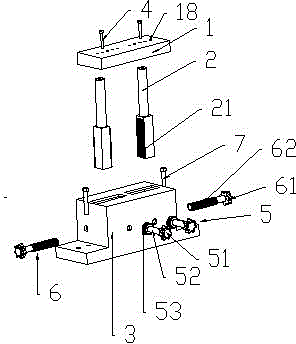

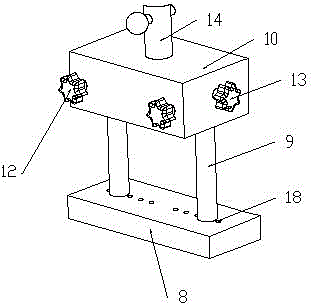

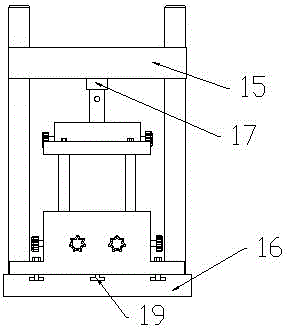

[0023] see figure 1 , figure 2 , image 3 and Figure 4 What is claimed is a fixture for component tension-compression vibration fatigue experiments, comprising an end fixture and an intermediate fixture connected to a vibration fatigue testing machine.

[0024] Wherein, the end fixing device includes a top fixing plate 1, a side fixing plate 2 and a bottom fixing plate 3, the top fixing plate 1 is connected with the side fixing plate 2 through a top fixing bolt 4, and the bottom fixing plate 3 is provided with a The up and down lifting adjustment device 5 and the left and right movement adjustment device 6 of the fixed plate 2. The bottom fixing plate 3 is provided with bottom fixing bolts 7 for integrally fixing the end fixing device on the foundation base 16 , and the top fixing plate 1 is also provided with spare bolts 18 .

[0025] The middle fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com