Film thickness measuring device

A technology for measuring device and film thickness, which is applied in the direction of measuring device, instrument, scientific instrument, etc., and can solve the problems that cannot be uniformly corrected, and cannot accurately calculate the thickness of Al film 102

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Hereinafter, the present invention will be described in detail using the illustrated embodiments.

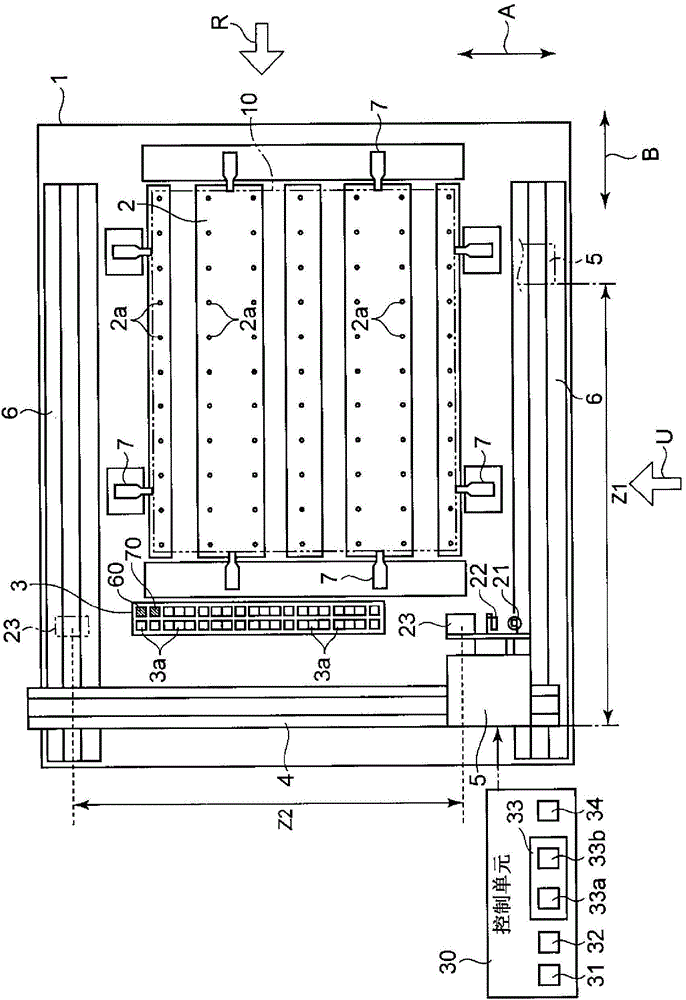

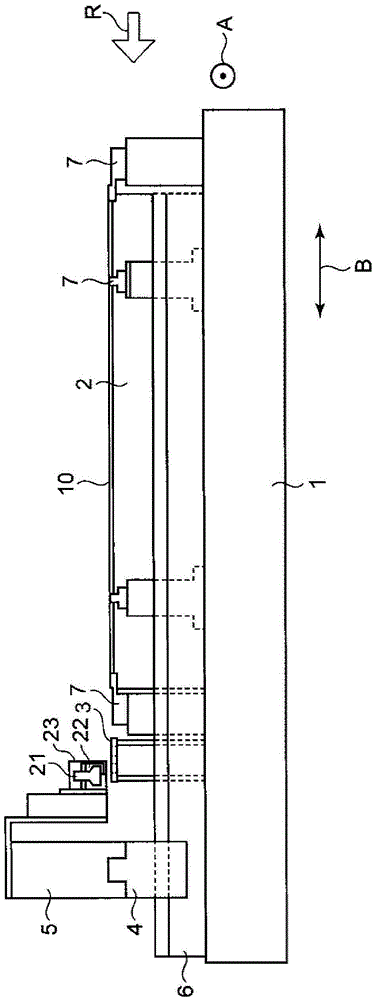

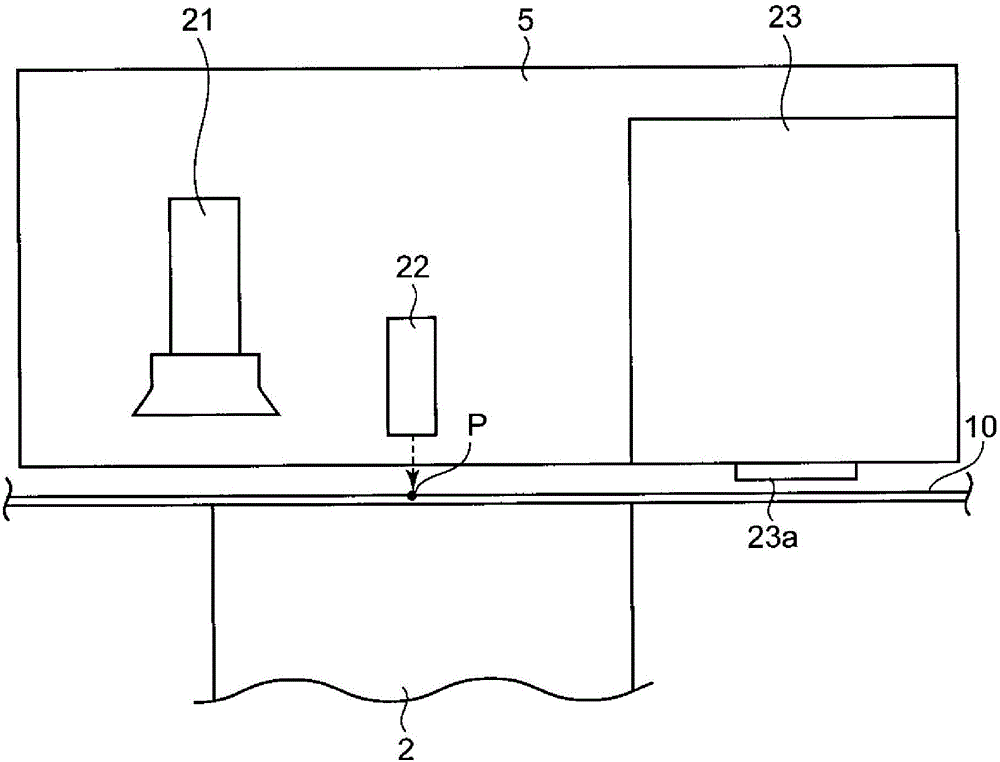

[0049] figure 1 It is a plan view showing the film thickness measurement device of one embodiment of the present invention. figure 2 From figure 1 A side view viewed in the direction of the arrow U. Such as figure 1 and figure 2 As shown, the film thickness measuring device has a base 1 , a substrate table 2 , a calibration table 3 , a gantry 4 , a slider 5 , a plurality of measuring devices 21 , 22 , 23 , and a control unit 30 .

[0050] The substrate stage 2 is provided on the base 1 and includes a plurality of stages. The film-formed product substrate 10 is placed on the substrate stage 2 .

[0051] The above-mentioned substrate table 2 is provided with a plurality of air holes 2a, and air is sucked in from the air holes 2a, whereby the product substrate 10 can be closely attached to the substrate table 2, and on the other hand, air is blown out from the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com