Automatic packaging system of cheeses

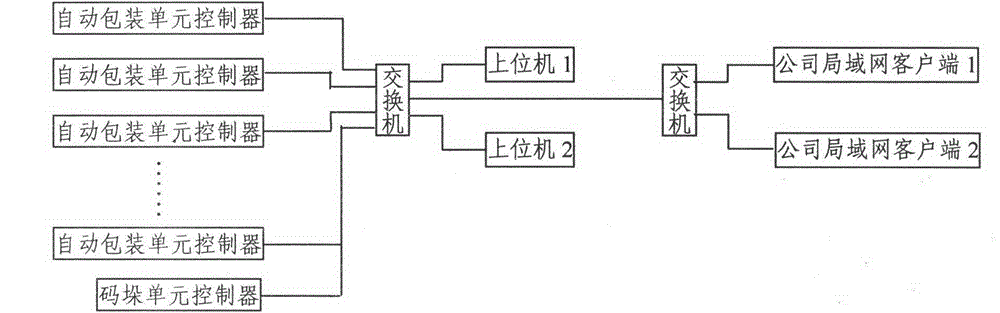

An automatic packaging and cheese yarn technology, applied in packaging, packaging protection, transportation and packaging, etc., can solve problems such as inability to meet the quality error of each woven bag, lack of fixed weight control links, and packaging lines difficult to meet domestic market demand, etc. The effect of reducing labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Two specific embodiments of the cheese automatic packaging system of the present invention are provided below, and the embodiments are only illustrations of the cheese automatic packaging system of the present invention, and do not constitute limitations to the claims of the present invention, and the unmentioned parts of the present invention are applicable in existing technology.

[0040] An embodiment of the package automatic packaging system of the present invention: the package production machine in this embodiment is an automatic winding machine, and the package is a tapered package.

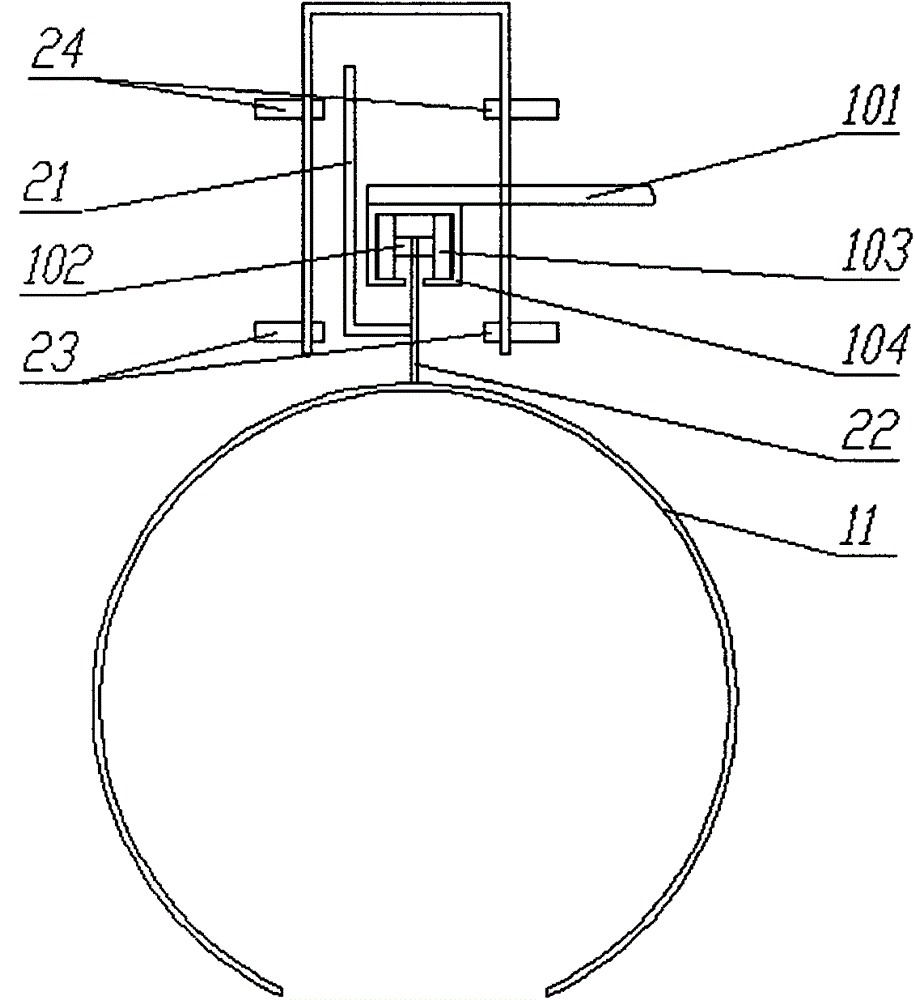

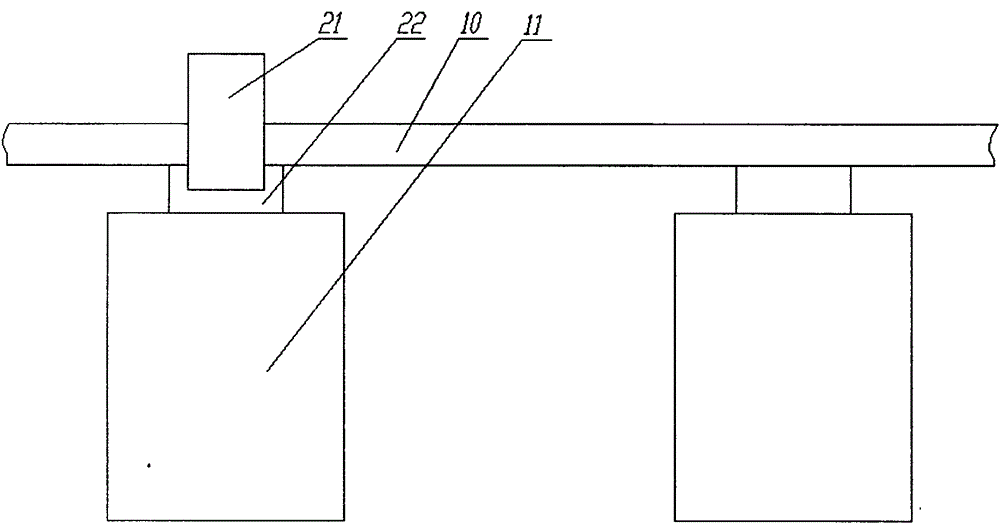

[0041] The cheese delivery device 1 is specifically (see figure 1 , figure 2 ): a circulating conveyor chain 10, conveyor chain roller 103 and conveyor chain roller shaft 102 passing through conveyor chain roller 103 are installed in its conveyor chain slideway 104, and a counting steel plate 22 is used for every 600mm spacing on the conveyor chain 10. A yarn carrier 11 is hung on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com