Cabinet

A kind of cabinet and sliding part technology, applied in the direction of cabinet/cabinet/drawer parts, electrical components, sealed shell, etc., can solve the problems of unfavorable cabinet heat dissipation, loss of cabinet cold air flow, hot air entering the cabinet, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

other Embodiment approach

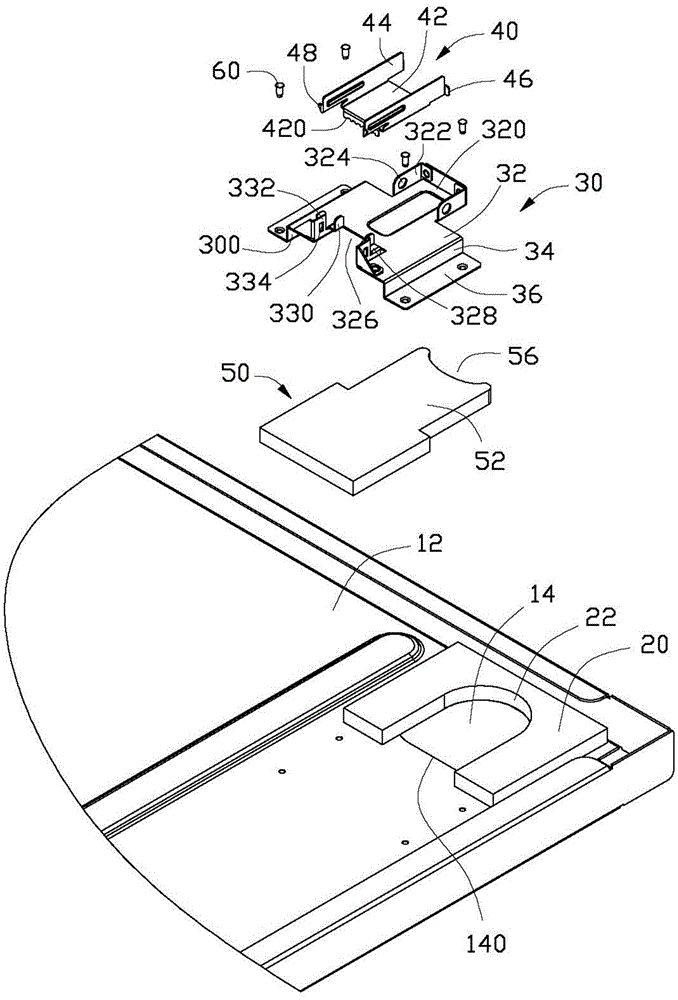

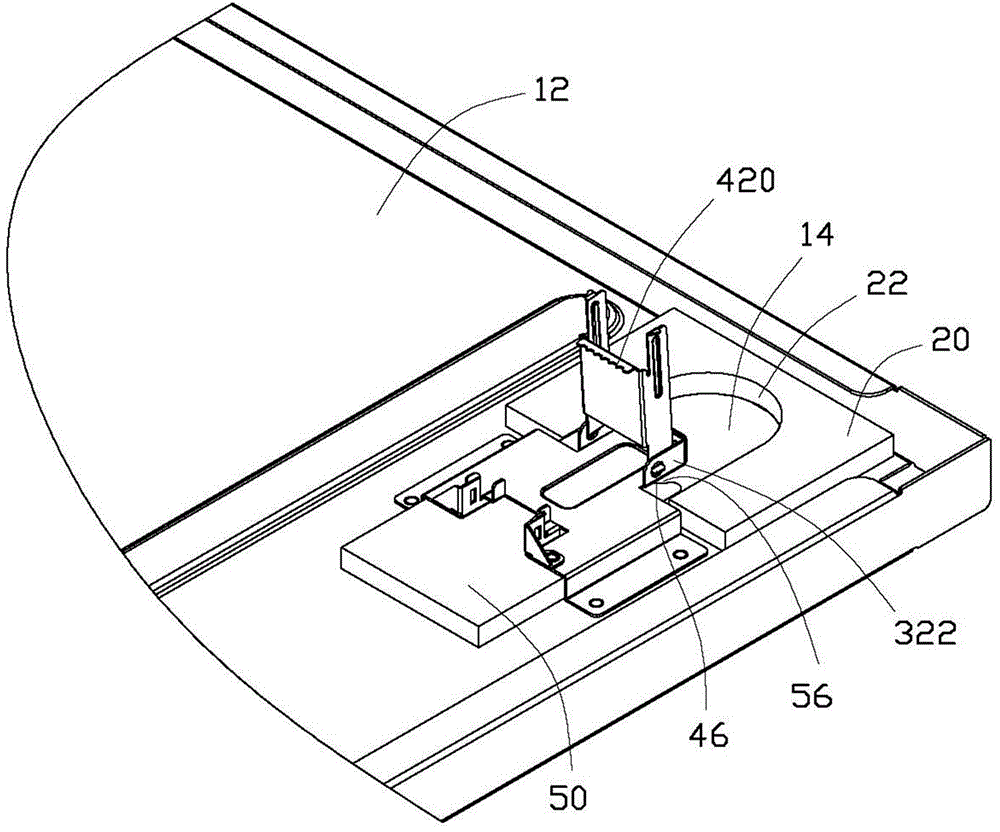

[0022] In other embodiments, the extension piece 320 of the mounting portion 30 may be omitted, and the two side arms 322 are protruded on two sides of the top surface of the connecting plate 32 .

other Embodiment approach

[0023] In other embodiments, the carrying piece 328 and the blocking piece 330 of the mounting portion 30 can be omitted.

other Embodiment approach

[0024] In other embodiments, the sliding portion 50 may also be fixed to the board body 12 in other ways. For example, screws are passed through the sliding part 50 and then locked into the board body 12 , or adhesive tape is used to press the sliding part 50 to the board body 12 , and so on.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com